You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aerobeez "BANSHEE" 91" Slick build

- Thread starter Xpress

- Start date

stangflyer

I like 'em "BIG"!

Well alrighty then.It's all good, but if you do it again you'll be needing to send that 70 twin to me

Xpress

GSN Sponsor Tier 1

Build time!!!!

First things first, gotta get her onto her feet. I started by bolting the landing gear in place- the hardware for the landing gear is inside of the same bag as the axles. There should be 4 washers and 4 lock washers, lock washers go on the nut side inside of the canister tunnel.

You will want to slip your gear cuffs on and glue them in place. There are lots of different ways to fit them on, but I opted to glue them using a silicone rubber-type glue (I actually had this stuff lying around without a label so I have no idea what brand it actually it ). Seems to be sturdy..

). Seems to be sturdy..

Next up, bolting said axles in place.

This is a bit of an important step that ensures the collars will stay in place, grinding some flat spots onto the axle. Just put your wheel on and test fit the pant on to see where the wheel needs to go. Mark the positions and grind a flat spot.

Next I slipped the inside collars on and slid the wheels in place.

Outside collar on.

Lastly, bolted the pants in place using 2 bolts and 2 washers.

I went ahead and bolted the vent plates in place right now, I will start cutting the vent holes out tomorrow when there's more energy. Glue the landing gear cover plate in place using medium CA, epoxy, silicone glue, etc. I used medium CA.

That's all for tonight. She's on her mains, more work will come in the next couple of days.

You may want to opt to use blue threadlocker on all of the bolts, I did so on the main gear bolts. It'll help keep all of your nuts and bolts in place, you wouldn't want to lose your nuts would you?

Don't threadlock the vent plates in place, they will eventually need to be removed for whatever maintenance you will need to do- the forward plate serves as an access point for the bottom cowl bolts.

First things first, gotta get her onto her feet. I started by bolting the landing gear in place- the hardware for the landing gear is inside of the same bag as the axles. There should be 4 washers and 4 lock washers, lock washers go on the nut side inside of the canister tunnel.

You will want to slip your gear cuffs on and glue them in place. There are lots of different ways to fit them on, but I opted to glue them using a silicone rubber-type glue (I actually had this stuff lying around without a label so I have no idea what brand it actually it

). Seems to be sturdy..

). Seems to be sturdy..Next up, bolting said axles in place.

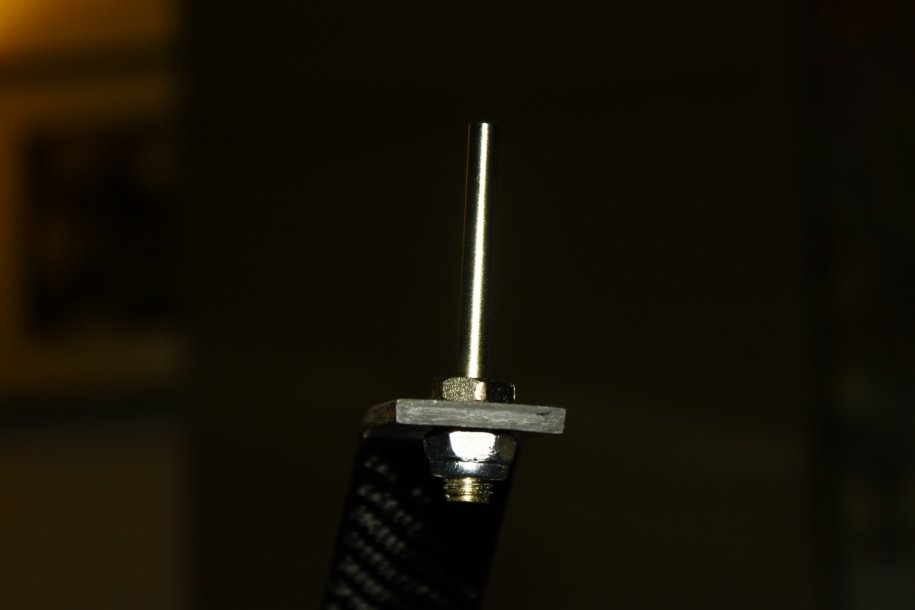

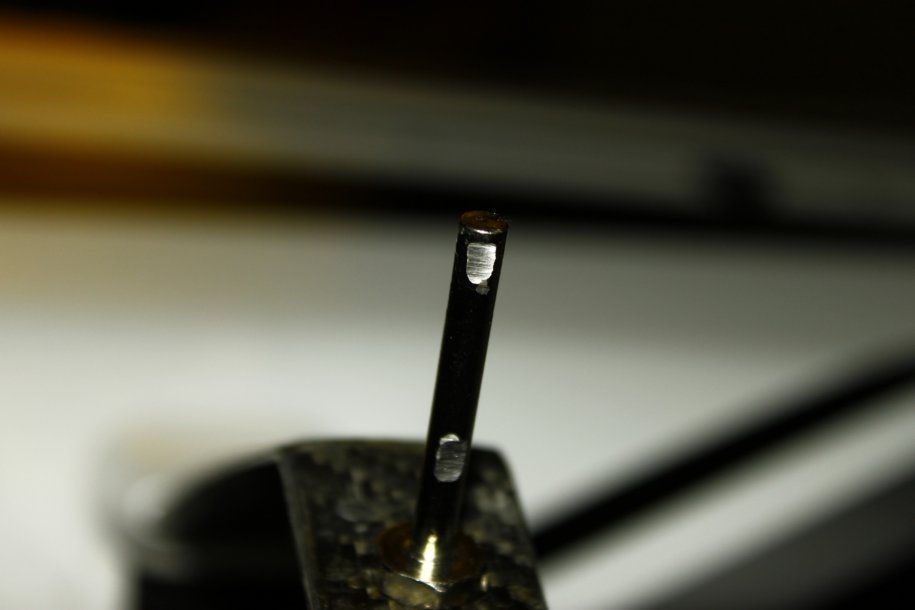

This is a bit of an important step that ensures the collars will stay in place, grinding some flat spots onto the axle. Just put your wheel on and test fit the pant on to see where the wheel needs to go. Mark the positions and grind a flat spot.

Next I slipped the inside collars on and slid the wheels in place.

Outside collar on.

Lastly, bolted the pants in place using 2 bolts and 2 washers.

I went ahead and bolted the vent plates in place right now, I will start cutting the vent holes out tomorrow when there's more energy. Glue the landing gear cover plate in place using medium CA, epoxy, silicone glue, etc. I used medium CA.

That's all for tonight. She's on her mains, more work will come in the next couple of days.

You may want to opt to use blue threadlocker on all of the bolts, I did so on the main gear bolts. It'll help keep all of your nuts and bolts in place, you wouldn't want to lose your nuts would you?

Don't threadlock the vent plates in place, they will eventually need to be removed for whatever maintenance you will need to do- the forward plate serves as an access point for the bottom cowl bolts.

Terryscustom

640cc Uber Pimp

Sorry one more side-track, I just bought some exhaust parts for some ES composite pipes I'll be installing soon. Saw that the 3dub 70 is back in stock: http://www.aircraftinternational.co...5/RtnTab/83/PageIndex/1/CatID/85/Default.aspx

It would have a hard time competing with the DA though, I'll say that with absolute confidence.

It would have a hard time competing with the DA though, I'll say that with absolute confidence.

stangflyer

I like 'em "BIG"!

That just looks wicked cool Tanner. Hey, if you get a minute and would be willing to do me a little favor... Would you grab an inside measurement of the cowl? Stopped over to pick up the 30% Pilot Yak from my buddy tonight. Doah....The cowl is too small for the 3dub. Plug cap to plug cap is too wide. Grrr.... So we're back to looking at the possibility of the Slick.Build time!!!!

First things first, gotta get her onto her feet. I started by bolting the landing gear in place- the hardware for the landing gear is inside of the same bag as the axles. There should be 4 washers and 4 lock washers, lock washers go on the nut side inside of the canister tunnel.

View attachment 48385

You will want to slip your gear cuffs on and glue them in place. There are lots of different ways to fit them on, but I opted to glue them using a silicone rubber-type glue (I actually had this stuff lying around without a label so I have no idea what brand it actually it). Seems to be sturdy..

View attachment 48381

Next up, bolting said axles in place.

View attachment 48382

This is a bit of an important step that ensures the collars will stay in place, grinding some flat spots onto the axle. Just put your wheel on and test fit the pant on to see where the wheel needs to go. Mark the positions and grind a flat spot.

View attachment 48386

Next I slipped the inside collars on and slid the wheels in place.

View attachment 48383

Outside collar on.

View attachment 48384

Lastly, bolted the pants in place using 2 bolts and 2 washers.

View attachment 48388

I went ahead and bolted the vent plates in place right now, I will start cutting the vent holes out tomorrow when there's more energy. Glue the landing gear cover plate in place using medium CA, epoxy, silicone glue, etc. I used medium CA.

View attachment 48387

That's all for tonight. She's on her mains, more work will come in the next couple of days.

View attachment 48389

You may want to opt to use blue threadlocker on all of the bolts, I did so on the main gear bolts. It'll help keep all of your nuts and bolts in place, you wouldn't want to lose your nuts would you?

Don't threadlock the vent plates in place, they will eventually need to be removed for whatever maintenance you will need to do- the forward plate serves as an access point for the bottom cowl bolts.

Xpress

GSN Sponsor Tier 1

That just looks wicked cool Tanner. Hey, if you get a minute and would be willing to do me a little favor... Would you grab an inside measurement of the cowl? Stopped over to pick up the 30% Pilot Yak from my buddy tonight. Doah....The cowl is too small for the 3dub. Plug cap to plug cap is too wide. Grrr.... So we're back to looking at the possibility of the Slick.

About 11 1/2" where the engine would sit. The 3W70 should fit perfectly inside without cutting, I know the DA70 will. Like I said the cowl is huge, I can fit my gigantic head in it

Xpress

GSN Sponsor Tier 1

Sorry one more side-track, I just bought some exhaust parts for some ES composite pipes I'll be installing soon. Saw that the 3dub 70 is back in stock: http://www.aircraftinternational.co...5/RtnTab/83/PageIndex/1/CatID/85/Default.aspx

It would have a hard time competing with the DA though, I'll say that with absolute confidence.

I'm one of those guys where bench comparisons don't mean much to me, I have to see the actual performance of the engine in the airplane (side by side preferably) before I jump to conclusions.

Terryscustom

640cc Uber Pimp

I'm one of those guys where bench comparisons don't mean much to me, I have to see the actual performance of the engine in the airplane (side by side preferably) before I jump to conclusions.

Exactly, I love they guys online that spout on how their "XYZ" airplane part is the best out there, but have never tried anything else.

Last edited:

Xpress

GSN Sponsor Tier 1

The servos I opted to go with for this airplane are the Hitec HSB-9485SH servos (9465 on the throttle).

These are our more budget friendly, steel gear equipped brushless servos that still feature a constant torque output, lower current draw, and an extremely linear and consistent speed throughout. The 9485 has 361oz/in of torque at either 6.0v or 7.4v, so what voltage you opt to run (be it LiFe, LiPo, or even a 5 cell nickel battery) doesn't matter, you still get the full torque output of the servo. The only changing variable for any of the Hitec brushless servos is the speed of the servo. At 7.4v, the 9485 is 0.15 which is still plenty quick for mostly any type of 3D flying.

Current draw is approximately 1/3-1/5 that of a conventional digital coreless equivalent, and when the servo stalls, it doesn't spike the current through the roof. The circuit is intelligent enough to identify when the motor inside stalls and can adjust the current flow accordingly. Some of the other guys that have been using them have been reporting extremely low current draw and are seeing MORE flights on a single charge- lets me run smaller flight batteries (the Thunder Power 2S 1900 RX packs are what I am using, should still be plenty for a day of fun) and save on flying weight. I'm looking forward to putting them into one of my own personal airplanes for long term use and experience.

FYI, the equivalent conventional digital coreless to the HSB-9485SH in our Hitec lineup is the HS-7954SH. With the 9485's constant torque output, it'll be able to push the surfaces just as well out at the limits of the servos throw. So if you're already running 7954's (or even 7955's) then you can very easily swap to the 9485 and see the same performance, if not better, all the while reducing your current draw.

These are our more budget friendly, steel gear equipped brushless servos that still feature a constant torque output, lower current draw, and an extremely linear and consistent speed throughout. The 9485 has 361oz/in of torque at either 6.0v or 7.4v, so what voltage you opt to run (be it LiFe, LiPo, or even a 5 cell nickel battery) doesn't matter, you still get the full torque output of the servo. The only changing variable for any of the Hitec brushless servos is the speed of the servo. At 7.4v, the 9485 is 0.15 which is still plenty quick for mostly any type of 3D flying.

Current draw is approximately 1/3-1/5 that of a conventional digital coreless equivalent, and when the servo stalls, it doesn't spike the current through the roof. The circuit is intelligent enough to identify when the motor inside stalls and can adjust the current flow accordingly. Some of the other guys that have been using them have been reporting extremely low current draw and are seeing MORE flights on a single charge- lets me run smaller flight batteries (the Thunder Power 2S 1900 RX packs are what I am using, should still be plenty for a day of fun) and save on flying weight. I'm looking forward to putting them into one of my own personal airplanes for long term use and experience.

FYI, the equivalent conventional digital coreless to the HSB-9485SH in our Hitec lineup is the HS-7954SH. With the 9485's constant torque output, it'll be able to push the surfaces just as well out at the limits of the servos throw. So if you're already running 7954's (or even 7955's) then you can very easily swap to the 9485 and see the same performance, if not better, all the while reducing your current draw.

Last edited: