cardenflyer

70cc twin V2

Can't wait to see this smoking it up in a hover on the deck!

Can't wait to see this smoking it up in a hover on the deck!

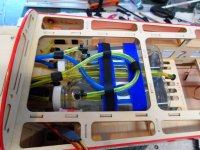

Got the smoke system installed yesterday. Doing a little research I'm finding that everyone's CG on this plane requires there batteries around the tank area, which wont work for this plane with 2 tanks. So I put the smoke pump up front hoping this will allow me to put the Lipos behind the wing tube.

The fuse has a removable canister tunnel plate, so I mounted the pump to it. Pump has 2 lines, one feeds right from tank threw a filter into the pump, then pump feeds oil out threw a one way valve into the smoke muffler. The muffler then heats the oil and creates smoke. Very simple to set up really.

View attachment 18764

ALthough this looks like a handy forward position to mount the smoke pump, I'm asking myself the question now: how will you be providing exit venting for airflow?

You've got the air intake holes in the front of the cowl, but where will that air exit the plane?

On my 30cc birds and my 50cc bird, there is a vent plate on the bottom of the cannister tunnel which can be used for exit air vents...but if you've got the cannister tunnel blocked with the smoke pump, that won't work for you...

perhaps mounting the smoke pump to the bottom of the motor box would work beter? Then you could leave the cannister opening off and provide exit air venting in the normal manner?

ALthough this looks like a handy forward position to mount the smoke pump, I'm asking myself the question now: how will you be providing exit venting for airflow?

You've got the air intake holes in the front of the cowl, but where will that air exit the plane?

On my 30cc birds and my 50cc bird, there is a vent plate on the bottom of the cannister tunnel which can be used for exit air vents...but if you've got the cannister tunnel blocked with the smoke pump, that won't work for you...

perhaps mounting the smoke pump to the bottom of the motor box would work beter? Then you could leave the cannister opening off and provide exit air venting in the normal manner?

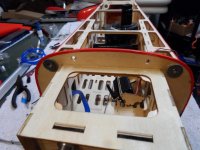

In really like the current mounting location, especially since the cowl design itself has a cooling vent built at the aft/bottom side.

Notice it in this picture how the bottom protrudes and has a hump? It's open to the rear for airflow to move through and out:

View attachment 18787