You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale 1/3 Scale Piper Tri Pacer Build - WE Technical Service Plans

- Thread starter TonyHallo

- Start date

Stevendavis

100cc

Me Too!I’m bad about never bothering with pants.

Wife gets on me when we're expecting company!

TonyHallo

640cc Uber Pimp

Got a few pieces glued together, 2 formers and sides are joined. The plans instruct you to score the sides and bend inward, an interesting way of doing it. You really have to score and leave only one ply to get the sides to bend as shown on the plans, I decided to glass the side to the former before moving on. The thicker plywood pieces on the outside are for alignment purposes only and will be removed. The sides bent inward behind the rear former, I have been soaking those with ammonia and weights to form the bends, it is difficult to get plywood to bend. The left side is bent in almost an inch, just started soaking the right side.

The drawing pack arrived, there is an index for each of the various short wing Pipers, it is not a complete set but is great asset none the less. One drawing I was hoping for is the main gear VEE assembly which happens to be missing. Even the Univar parts web page doesn't have a photo!

The drawing pack arrived, there is an index for each of the various short wing Pipers, it is not a complete set but is great asset none the less. One drawing I was hoping for is the main gear VEE assembly which happens to be missing. Even the Univar parts web page doesn't have a photo!

TonyHallo

640cc Uber Pimp

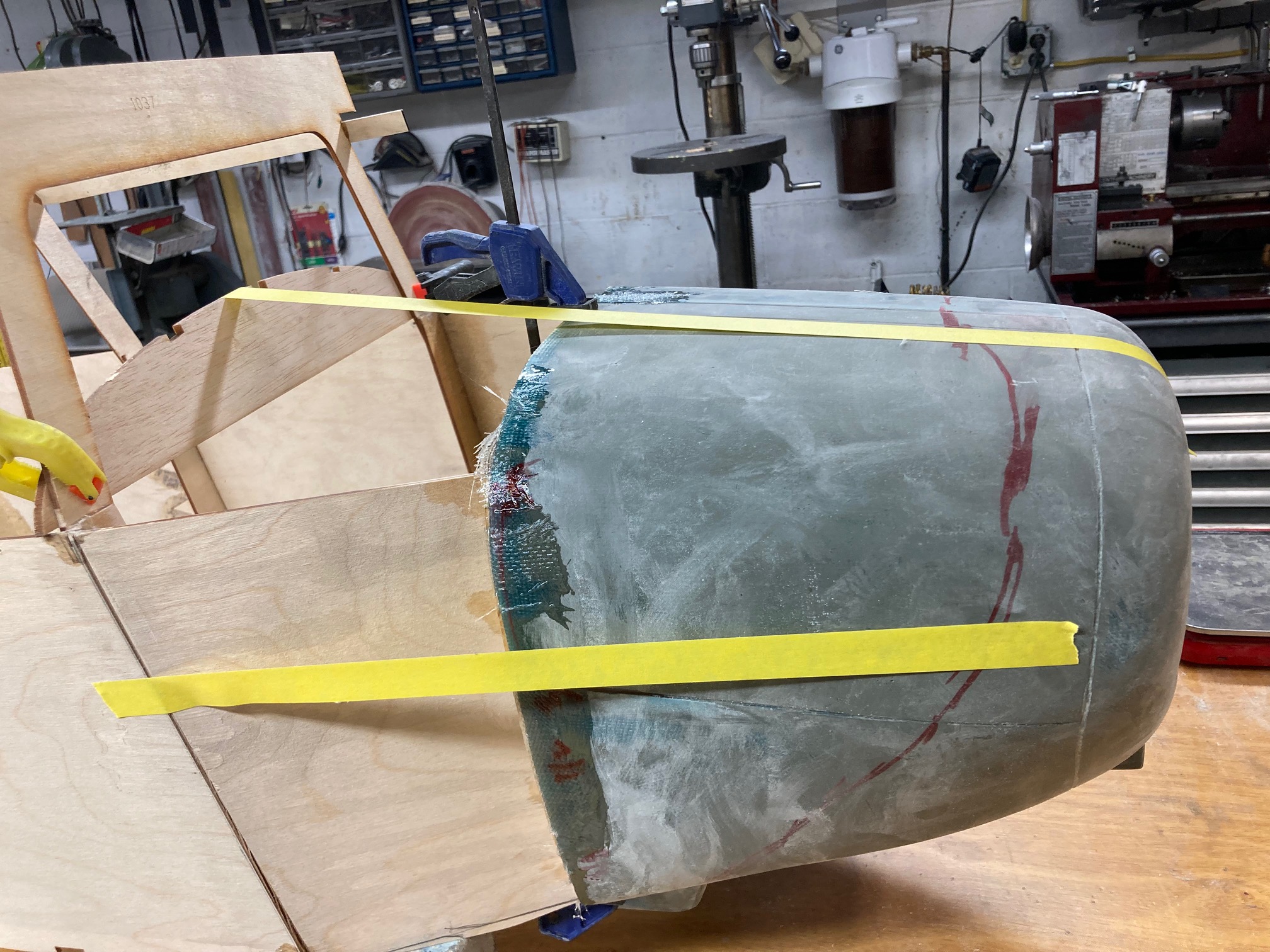

I'm at a decision point now, the cowl is fitted however I'm not keen on the way the plane is designed. According to the three view the nose tapers in slightly from the windshield to the nose bowl. The plans show a greater taper from the windshield to the back of the cowl while the cowl is nearly straight. The cowl is fitted on and aligned to the centerline. I thinking to fill the low areas with Bondo to form a more gradual taper. This might close to 3/4" thick in some areas. I had planned to make a new mold and cowl anyway so it is only a minor set back. The red line indicates the tangent point where the Bondo will extend to. The cowl is getting glassed on the the balsa formers and I plan to set the build aside for a while as weather is improving and it is time to think about paint.

Attachments

TonyHallo

640cc Uber Pimp

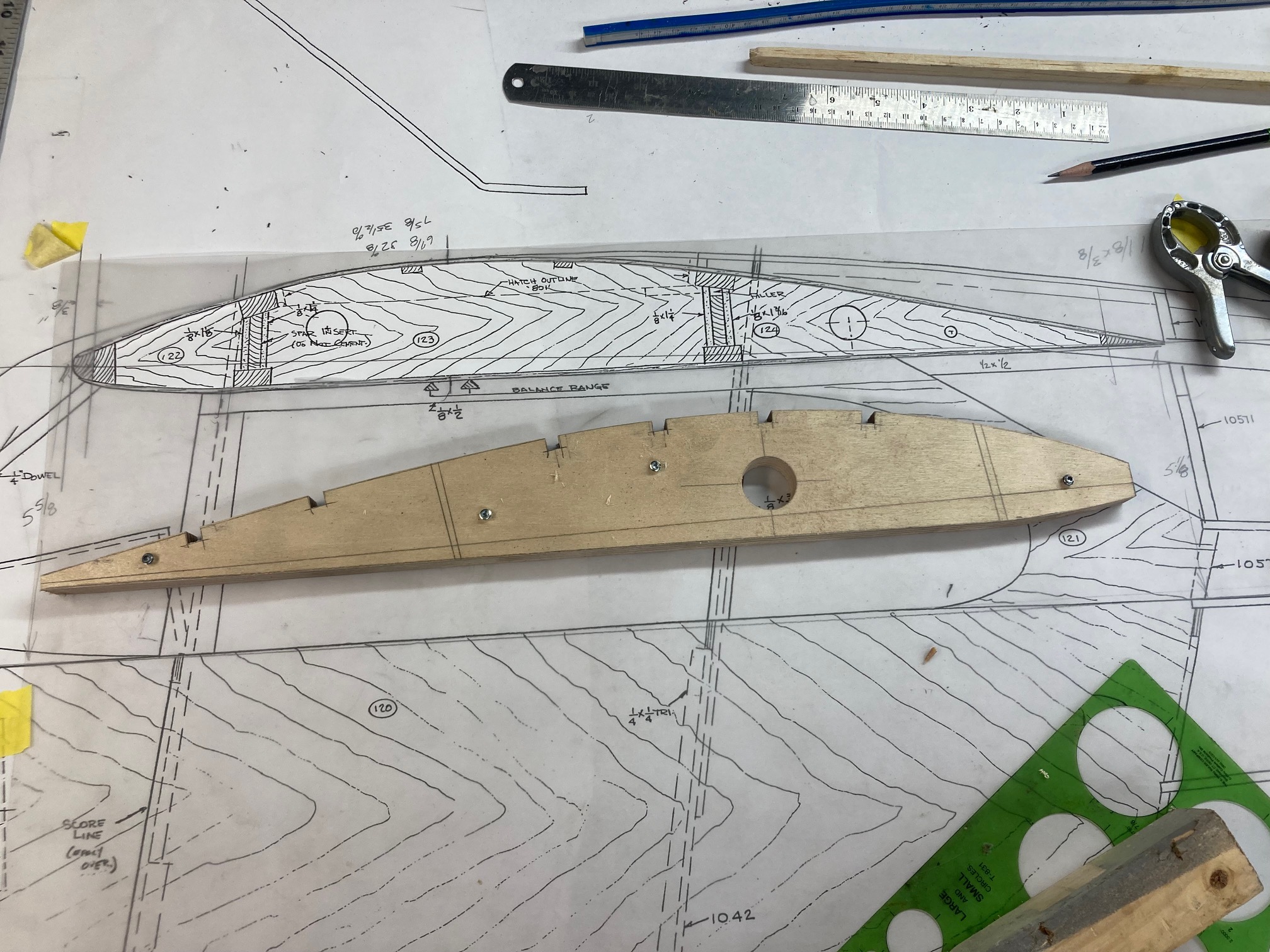

Decided to add a little more strength to the upper part of the fuselage before cowl modification's. Installing a 1" wing tube rather than the designed wing jointers, a lot less parts. The photo below shows the original rib, three airfoil pieces, four odd shaped pieces of balsa captured between the four spar caps. And there are four of these on the top of the fuselage.

Since I don't own a CNC or a laser cutter I had to rely on the old trusty SCS (Stack, Cut, Sand) method to produce four identical profiles. Still need to add a few lighting holes aft of former 4 and on the outer most rib sections. The drawing shows the wing incidence at 1.3 degrees positive from top of the fuselage sides.

Since I don't own a CNC or a laser cutter I had to rely on the old trusty SCS (Stack, Cut, Sand) method to produce four identical profiles. Still need to add a few lighting holes aft of former 4 and on the outer most rib sections. The drawing shows the wing incidence at 1.3 degrees positive from top of the fuselage sides.