stangflyer

I like 'em "BIG"!

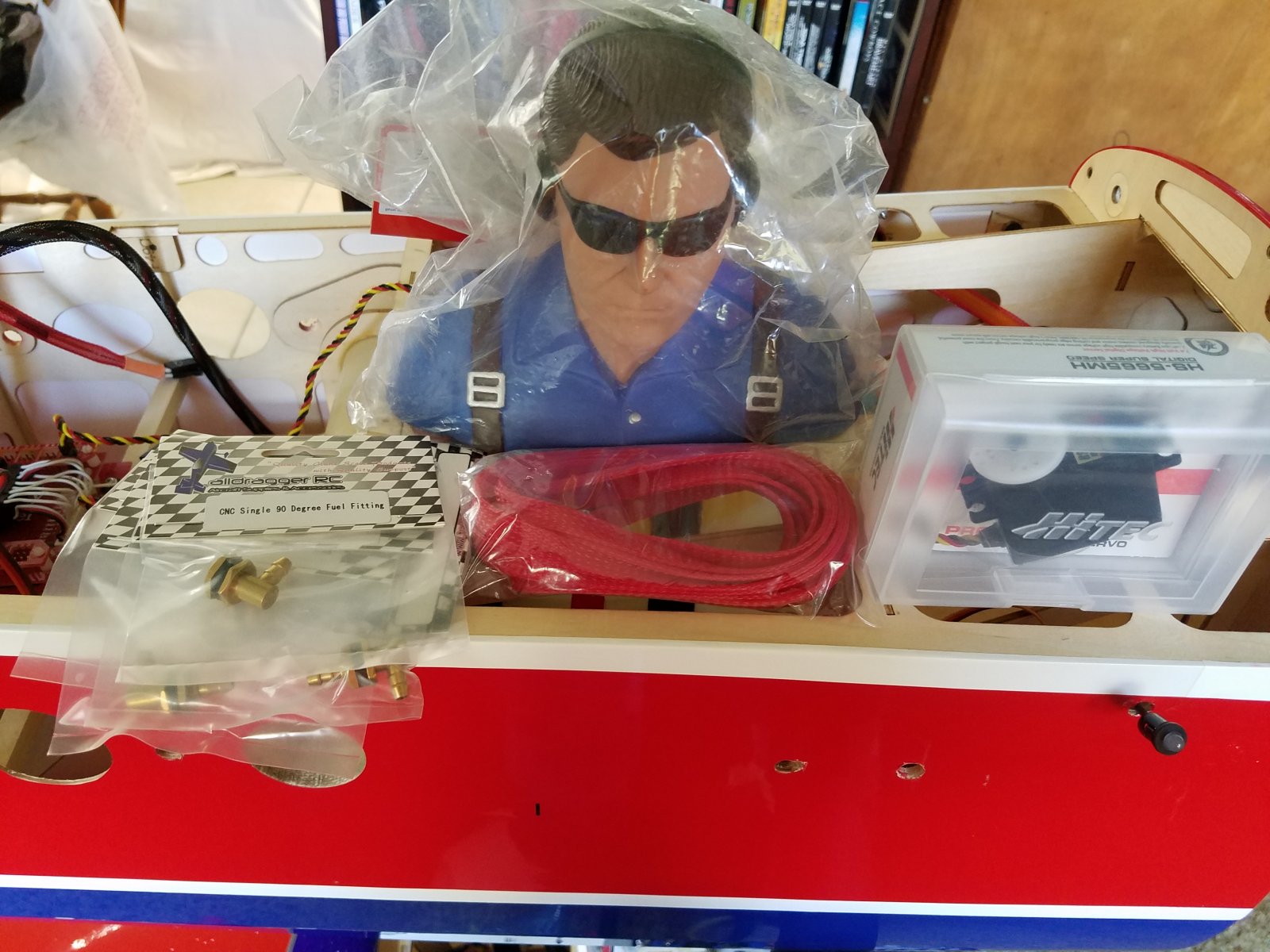

Oh how sweet it is. Lookie what I got. Parts...yay. The Edge will be real close tonight.

I have never tried it for that one reason, to soft.How well do planers plane balsa wood I was under the impression the it could not be planed to soft.

I was just about to ask the same question on how he ends his snakeskin.@stangflyer are you using heat shrink to seal the ends of the snake skin.

I tried it once it made a mess. And the thickness was all over the place, even with a new set of blades. And that was on General machine which is one of the best. I guess the only way is on a big sanding machine and they are expensive.I have never tried it for that one reason, to soft.

It is heat shrink tubing. It is about the nicest way I know of in terminating the ends on the snake skin. I have discovered that if you use just a little heat from your heat gun to shrink the tubing it does real nice job. But also does not damage the fuel tubing or any wires.@stangflyer are you using heat shrink to seal the ends of the snake skin.

The fuel fittings are double Barbed fittings. I have yet to have any come loose. It seems the 1/8 inch fuel tubing is a very good fit for the double Barbed fuel fittings. I have also found that if I have to replace a tube for whatever reason or do a replumb, I usually have to split the side of the tygon fuel tubing in order to get it off because it is so tight on the fittings.I was just about to ask the same question on how he ends his snakeskin.

Do have second question the fuel tank connections the gold colour ones have the right angle connection. Have you ever had one of the ends come lose on the fitting.