Been a bit of progress, since I have been running around all day, at work, and before work and after wards, I added some more time to Fuselage 1. Great Advice I received: DO not start on Fuselage 2, until I get Fuselage 1 all framed and the phenolics glued in. Once they are glued in, I can remove fuselage 1 from build table, and then start over with step 3, 4, 5, and 6 of the fuselage construction. SO far, for Fuselage 2, I have the TRUSS built, but it is not sheeted, and the plywood phenolic supports are not glued on yet.

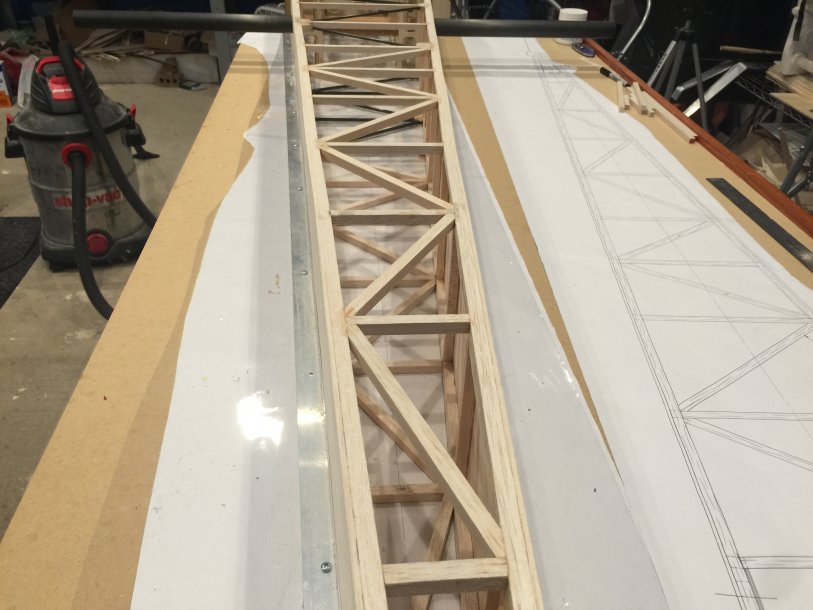

SO here we are, back on Fuselage 1, and this is what has been done and completed this morning:

all of the top and bottom cross braces are glued in.

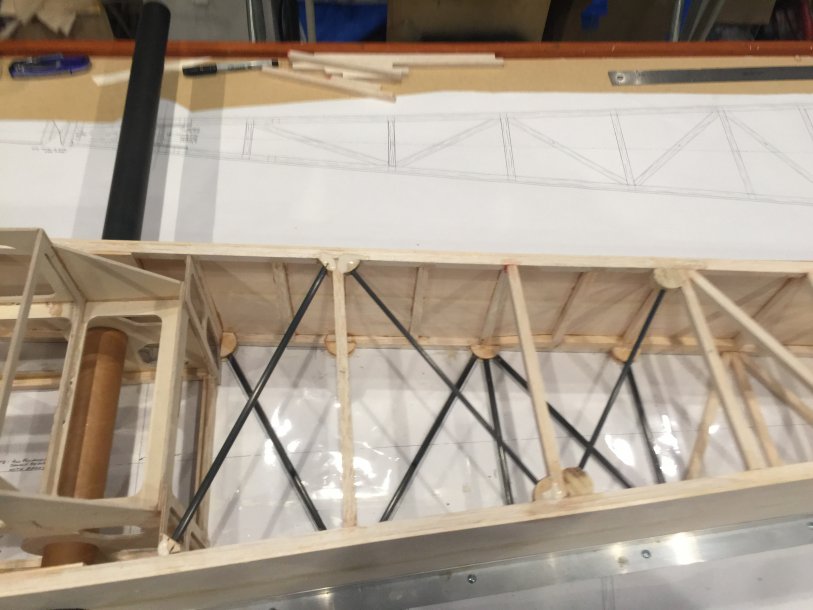

I used carbon fiber rods for the area under the canopy/hatch.

the top cross braces run in an opposite direction to the bottom cross braces. (this is on the plans).

here is to demonstrate the true and straight fuselage sides....

you can again see the canister tunnel and see the "straight" aspect of the bottom of the fuselage.

I like this picture! It is so cool!!! this is before the phenolics are glued in.

time to now start looking at the symmetry between the wing tube and stab tube and the fuselage. Will get into this more next.

SO here we are, back on Fuselage 1, and this is what has been done and completed this morning:

all of the top and bottom cross braces are glued in.

I used carbon fiber rods for the area under the canopy/hatch.

the top cross braces run in an opposite direction to the bottom cross braces. (this is on the plans).

here is to demonstrate the true and straight fuselage sides....

you can again see the canister tunnel and see the "straight" aspect of the bottom of the fuselage.

I like this picture! It is so cool!!! this is before the phenolics are glued in.

time to now start looking at the symmetry between the wing tube and stab tube and the fuselage. Will get into this more next.