rodman

50cc

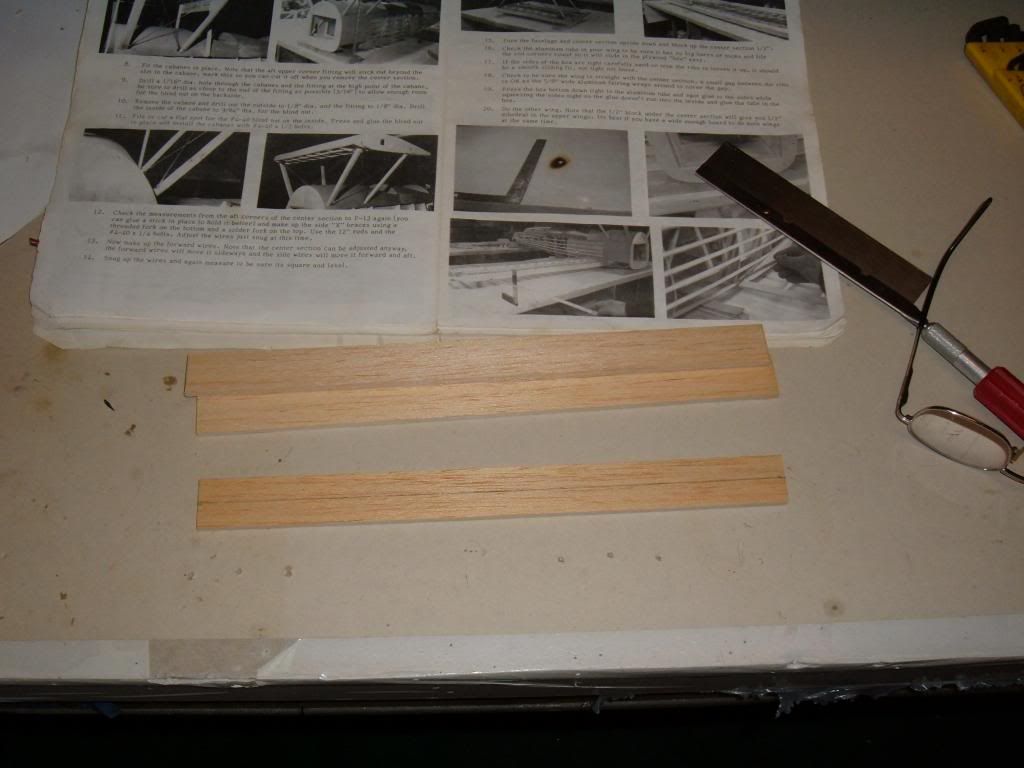

While I was messing around with the fire wall I figured out about where the throttle and choke linkages should go

I did a little cutting on the fiber glass cowling that goes behind the engine

This is just a ruff cut to make it easier to handle

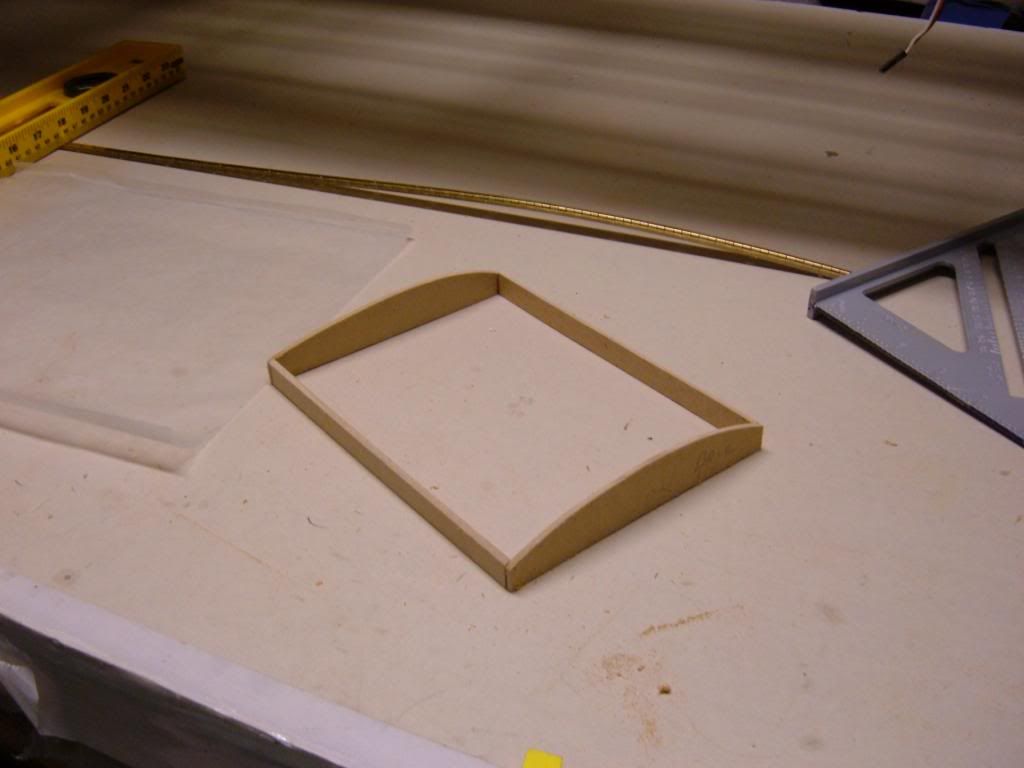

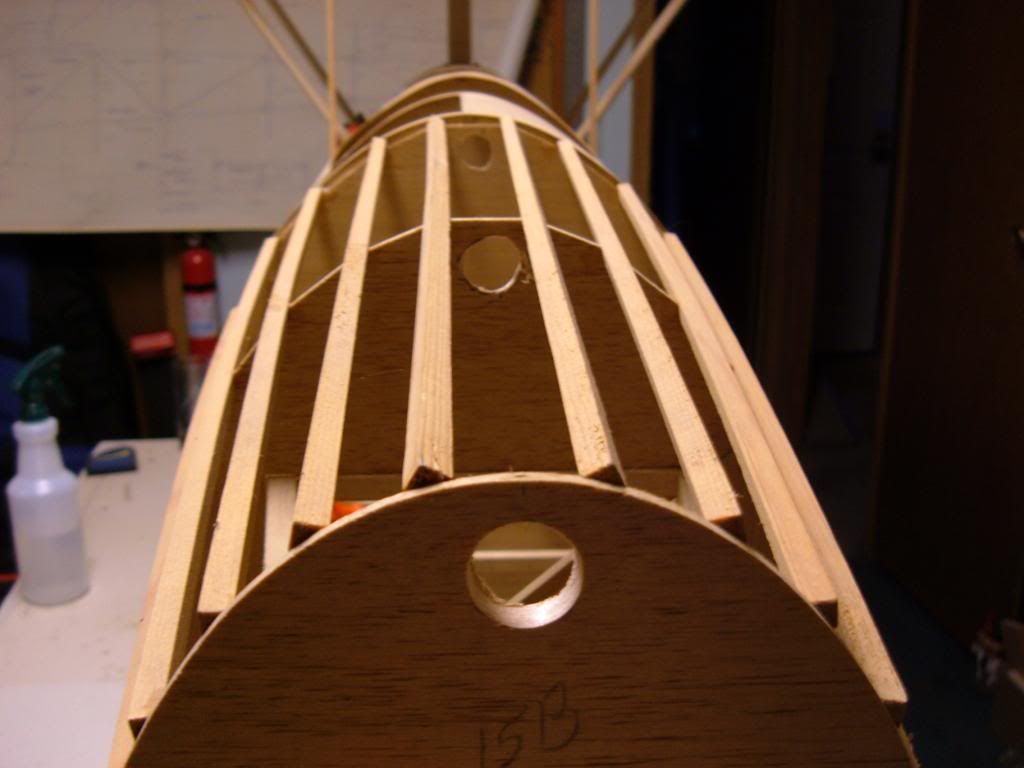

now I have to decide what to tackle next most likely it will be mounting and cutting

the cabanes for the upper wings center section

this is critical that the measurements are correct so I'll be taking my time with this one.

I did a little cutting on the fiber glass cowling that goes behind the engine

This is just a ruff cut to make it easier to handle

now I have to decide what to tackle next most likely it will be mounting and cutting

the cabanes for the upper wings center section

this is critical that the measurements are correct so I'll be taking my time with this one.