Fibertech

70cc twin V2

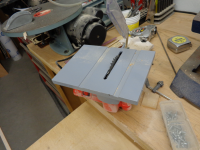

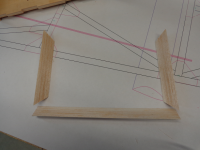

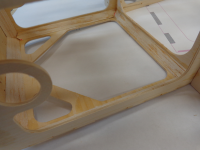

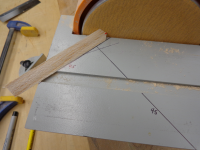

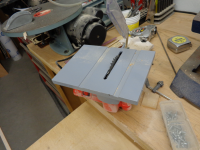

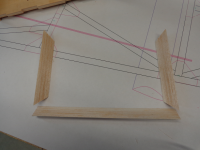

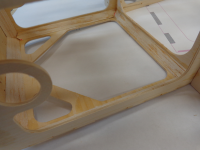

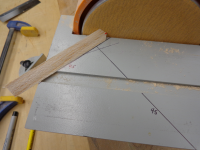

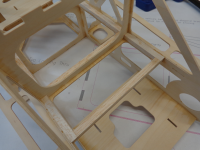

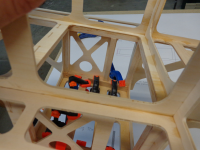

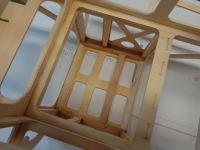

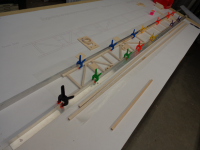

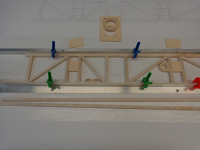

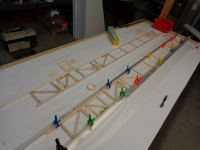

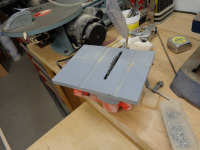

I was able to get some more done over the weekend. Now that I have all the parts joined for a test fit on the motor box it was time to start on gluing. I didn’t glue the top plate or the landing gear plate in at first to allow an easier access to fitting the balsa tri stock. Two of my machine friends are the little belt sander and the small table saw. Both are just cheap machines purchased from Harbor Freight but work great for this type of work. I started with the ½” tri-stock and fit it to the bottom corner. Same time I cut one for the top. I glued in the one for the bottom only. Then marked the length of the verticals for the two side corners and cut 45deg angles on both. I then glued the top in place and then the tri-stock. Once the front was done I moved onto the tri-stock for the top section.