TonyHallo

640cc Uber Pimp

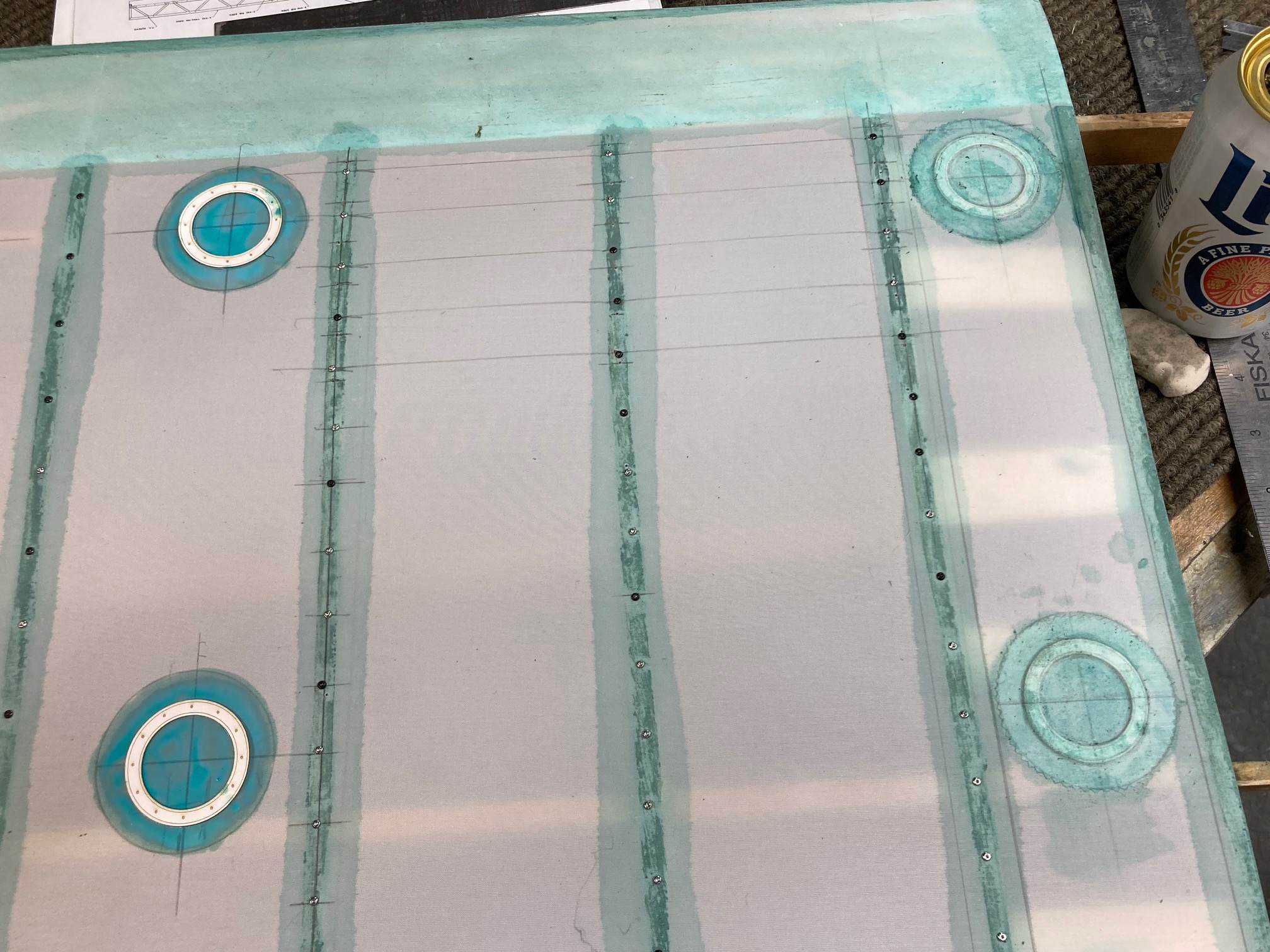

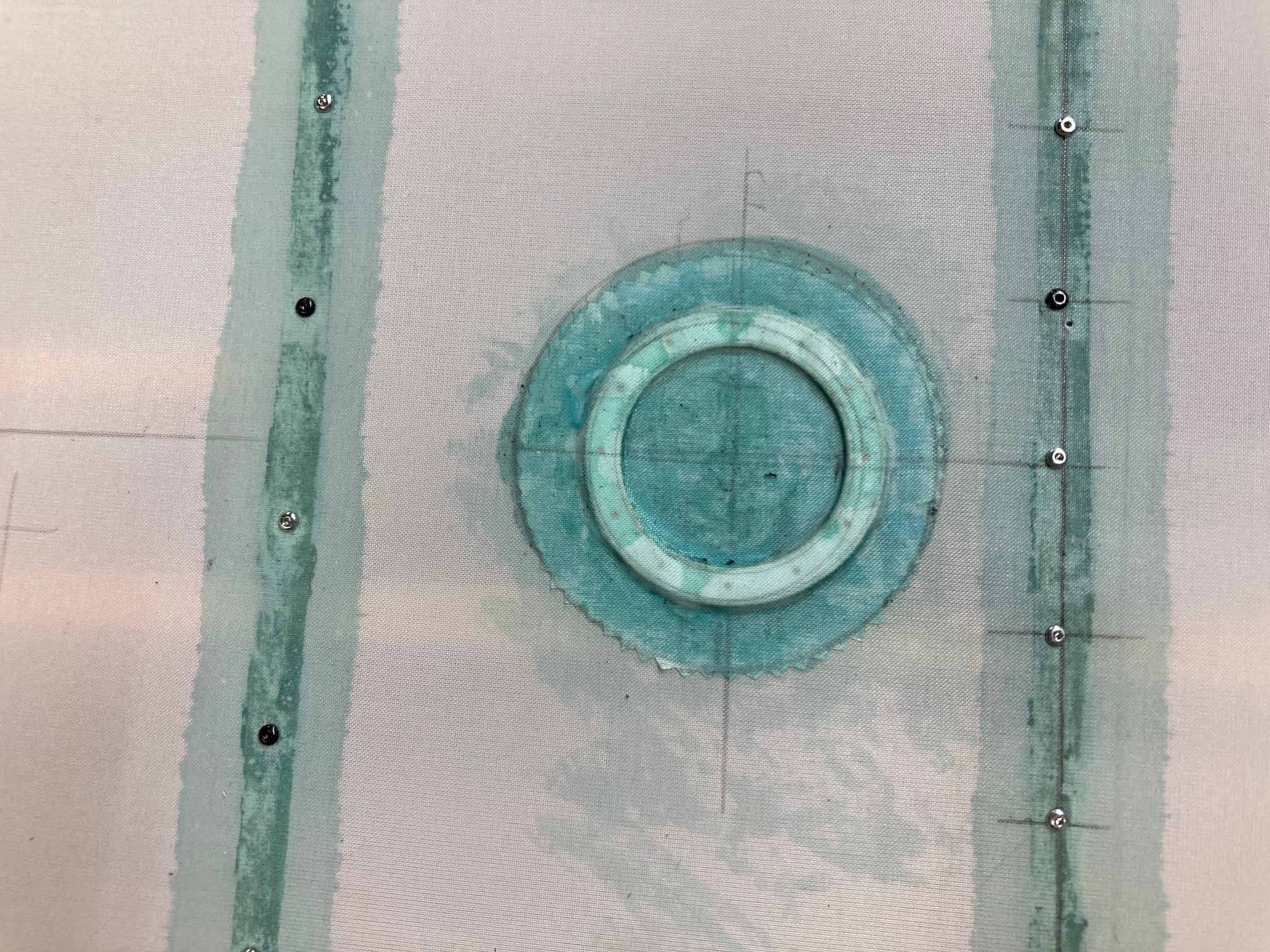

The fabric arrived today, put the top fabric on and shrunk all the fabric to 250 degrees. Then started on the inspection rings. I really do like the way the rings look when covered with the doily. Four are done, nine more to go, it takes 15 minutes or so to get the doily ironed down around the inspection ring since only working with the tip of the iron. I enjoy every one of them.