Alky6

150cc

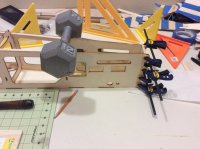

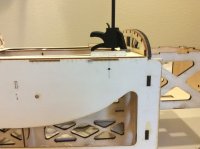

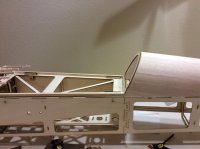

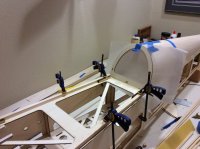

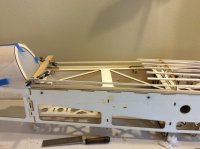

Talking with Al Young this week, they are working on a new prototype scale airframe. It is the Ashcraft DR-109 (radial version) with the round fuse. Pretty flipping cool! Should add some great variety to available kits to build for somethig different! Here is a link to the ashcraft page and some pics of construction progress.

http://www.ashcraftaeroworks.com/newprojects_landing.html

http://www.ashcraftaeroworks.com/newprojects_landing.html

Last edited:

. So I cut and sanded the old sheeting off and went and picked up some replacement balsa.

. So I cut and sanded the old sheeting off and went and picked up some replacement balsa.