You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Prop failure....... Have you had one??

- Thread starter Terryscustom

- Start date

Bunky.F.Knuckle

150cc

I've seen most of them delam. Not a pleasant sound when they do. Seen a Mejzlik 2 blade delam last year. Seen Hover props blow apart.

Snoopy1

640cc Uber Pimp

Looking at all specifications and the bolt type. For example if you are taking a 5M up to 90 in-lbs you are about 90% of the bolt yield. A lot of unknowns take place when tightening bolts, grease washers etc. just to explain something, when we were building high precision equipment our torque wrenches were calibrated once a week and if it was critical the torque wrench was calibrated at the number. The best torque wrenches are at best +/- 10%. If you do the numbers 6 -5M bolts will lift a car and our planes can at best do 50 lbs thrust of pull on 6 or even 4 bolts. Please note just trying to help and this is all just a suggestion. Please note that 12.9 class bolt is one of the best but if you look at the stress/ strain curve of it at that point it is very steep and there is very little room to play with before the bolt is at yield point. I know what I would recommend, but as you can understand that I am apprehensive.

Seeing a picture of six bolts and only one failed. The conclusion is, but let me make it clear that making a conclusion from just a picture can be dangerous and or incorrect. But if only one bolt failed and the other 5 after inspection are ok then I would say the bolt that failed was the only one carrying the load.

Seeing a picture of six bolts and only one failed. The conclusion is, but let me make it clear that making a conclusion from just a picture can be dangerous and or incorrect. But if only one bolt failed and the other 5 after inspection are ok then I would say the bolt that failed was the only one carrying the load.

stangflyer

I like 'em "BIG"!

So since this thread has brought about many experiences and insights, I'm noticing a large number of delaminating Biela props. This is concerning as my son is using a 32x12 two blade Biela on his DLE 222 on his big PAU Edge. Is there a significant risk or mitigating factor with the Biela props? Are they more susceptible to delamination verses Falcon, Mezjlike or other brands? I'd sure hate to see that gorgeous bird lost due to an inferior prop.

Terryscustom

640cc Uber Pimp

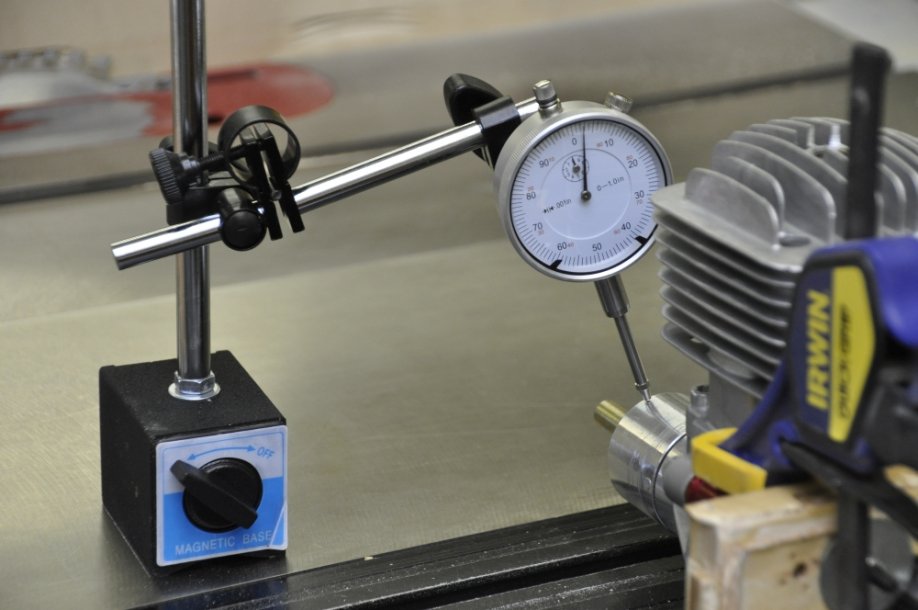

Well the good news is that at the front of the hub I only have .0025" of runout and at the very tip of the prop shaft there is .0040". So the engine should be good to go for LAW's new Decathlon. I'm going to try to pick up a prop down at Joe Nall next week.

Attachments

49dimes

Damn I'm hungry

Just my .02.......

Engine Hub.....Aluminum.

Prop Bolt.....Steel.

Threads in the hub will weaken first. I have been trying some stainless steel threaded inserts on small glow exhaust bolt holes and must say the tension is much better and have not loosened like the stock threads would. I wonder if this would be a better way to do the hubs on our large gassers?

Engine Hub.....Aluminum.

Prop Bolt.....Steel.

Threads in the hub will weaken first. I have been trying some stainless steel threaded inserts on small glow exhaust bolt holes and must say the tension is much better and have not loosened like the stock threads would. I wonder if this would be a better way to do the hubs on our large gassers?

Last edited:

Bill Vargas

50cc

Hi Snoopy1, appreciate the wordsLooking at all specifications and the bolt type. For example if you are taking a 5M up to 90 in-lbs you are about 90% of the bolt yield. A lot of unknowns take place when tightening bolts, grease washers etc. just to explain something, when we were building high precision equipment our torque wrenches were calibrated once a week and if it was critical the torque wrench was calibrated at the number. The best torque wrenches are at best +/- 10%. If you do the numbers 6 -5M bolts will lift a car and our planes can at best do 50 lbs thrust of pull on 6 or even 4 bolts. Please note just trying to help and this is all just a suggestion. Please note that 12.9 class bolt is one of the best but if you look at the stress/ strain curve of it at that point it is very steep and there is very little room to play with before the bolt is at yield point. I know what I would recommend, but as you can understand that I am apprehensive.

Seeing a picture of six bolts and only one failed. The conclusion is, but let me make it clear that making a conclusion from just a picture can be dangerous and or incorrect. But if only one bolt failed and the other 5 after inspection are ok then I would say the bolt that failed was the only one carrying the load.

Looking at all specifications and the bolt type. For example if you are taking a 5M up to 90 in-lbs you are about 90% of the bolt yield. A lot of unknowns take place when tightening bolts, grease washers etc. just to explain something, when we were building high precision equipment our torque wrenches were calibrated once a week and if it was critical the torque wrench was calibrated at the number. The best torque wrenches are at best +/- 10%. If you do the numbers 6 -5M bolts will lift a car and our planes can at best do 50 lbs thrust of pull on 6 or even 4 bolts. Please note just trying to help and this is all just a suggestion. Please note that 12.9 class bolt is one of the best but if you look at the stress/ strain curve of it at that point it is very steep and there is very little room to play with before the bolt is at yield point. I know what I would recommend, but as you can understand that I am apprehensive.

Seeing a picture of six bolts and only one failed. The conclusion is, but let me make it clear that making a conclusion from just a picture can be dangerous and or incorrect. But if only one bolt failed and the other 5 after inspection are ok then I would say the bolt that failed was the only one carrying the load.

Yup, I hear ya. Some new M5-60 bolts are in place now,,, but I do have a wee bit of reserve as to the structural integrity of the prop hub itself. Meaning the Heat Soaking the prop hub receives after the engine is shut down. Still, it leaves un-answered questions about the prop and its contributing factors with bolts breaking.

Bolt fatigue I understand and have seen in full size. Its just never happened to me in a very long time. Its a new prop and all the other props used never once an issue with the bolts,,, until I put this new prop on. It leads me to point the finger at the new prop or did that one bolt just time out because of the new prop?

Terryscustom

640cc Uber Pimp

Mowed the field and found a chunk of the Falcon right in the middle. Might have fallen off the plane during landing, otherwise it flew about 150 yards from the disintegration.

Wow, I bet it did fly off the plane. I killed the engine just as I got over the short grass and it was visibly only half a prop. THAT is crazy to toss a piece of wood all the way back to the field from where it happened!!! Considering where we picked up the rest of the canopy and the muffler extension that was all of 100-150 yards!!!