Terryscustom

640cc Uber Pimp

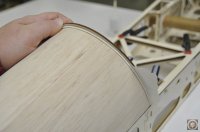

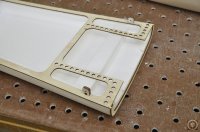

Next is the optional split ailerons and the final end caps. Always cool when the last of the foam is covered and you know you're almost done building!!

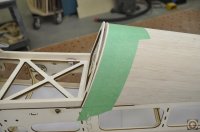

I use my miter saw to split the ailerons. The cut is 90 degrees form the hinge line, but you must put the aileron back into the foam what was cut out when the ailerons were cut out. That way the cut will be perpendicular to the horizontal center of the wing (see pics). Mark the end of the inner aileron and then 3/16" out from there.

On the elevator you also have to remove some stock from the inner edge to give plenty of clearance next to the fuselage. I normally take off 3/8". All of these foam areas that are exposed now get sheeted with 1/16" balsa scraps from the sheeting process.

I use my miter saw to split the ailerons. The cut is 90 degrees form the hinge line, but you must put the aileron back into the foam what was cut out when the ailerons were cut out. That way the cut will be perpendicular to the horizontal center of the wing (see pics). Mark the end of the inner aileron and then 3/16" out from there.

On the elevator you also have to remove some stock from the inner edge to give plenty of clearance next to the fuselage. I normally take off 3/8". All of these foam areas that are exposed now get sheeted with 1/16" balsa scraps from the sheeting process.

Attachments

Last edited: