gyro

GSN Contributor

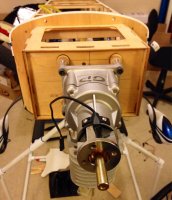

Continuing to get some work done, a little at a time. Right now, I've got the aileron and rudder control horns drying, and then I'll install the hinges.

One thing to note, is that there are three slots available for the aileron control horns in the wings. Following @bbrown2828's guess/suggestion on one of his builds, I choose the outboard pair to use with the surface mount servo spot, where as someone using the recessed servo location would use the inboard pair.

So, more on the wings....

First, add some thin ca to the anti rotation pins. They look very dry and soaked up a ton of glue.

On to the aileron servos and the recessed pocket. While I think the recessed look is cool, to me it's not strong enough for a 3D plane pushing 300+ oz/in torque to some big ailerons. So, I chose to install my servos in the traditional surface mount spots (also built in directly adjacent to the pocket).

Now my gripe: I've still got the pocket cover and slot to deal with on the wing. No screws for the cover were included in my kit but I had some in parts box to use. It's really cool to have the option to pick, but I think the recessed pocket should be covered over like the surface mount spot. Then, you decide which you want and cut the covering accordingly. The cover with slot can be included in the parts kit with the plane for those who need it.

since I chose not to use the recessed location, my underwing looks a little messy to me. I think I'll eventually add some black covering over the open cutout.

One thing to note, is that there are three slots available for the aileron control horns in the wings. Following @bbrown2828's guess/suggestion on one of his builds, I choose the outboard pair to use with the surface mount servo spot, where as someone using the recessed servo location would use the inboard pair.

So, more on the wings....

First, add some thin ca to the anti rotation pins. They look very dry and soaked up a ton of glue.

On to the aileron servos and the recessed pocket. While I think the recessed look is cool, to me it's not strong enough for a 3D plane pushing 300+ oz/in torque to some big ailerons. So, I chose to install my servos in the traditional surface mount spots (also built in directly adjacent to the pocket).

Now my gripe: I've still got the pocket cover and slot to deal with on the wing. No screws for the cover were included in my kit but I had some in parts box to use. It's really cool to have the option to pick, but I think the recessed pocket should be covered over like the surface mount spot. Then, you decide which you want and cut the covering accordingly. The cover with slot can be included in the parts kit with the plane for those who need it.

since I chose not to use the recessed location, my underwing looks a little messy to me. I think I'll eventually add some black covering over the open cutout.