You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale RCM 1/3 Scale Champ Build

- Thread starter TonyHallo

- Start date

TonyHallo

640cc Uber Pimp

Got a little time yesterday on the Champ, working on the landing gear. As previously posted the new gear is 3/4" longer. The original design used 4-40 screws as the hinge pins and hinged portion was riding on the threads, never cared for that so I decided to fit the main struts with 1/4" brass bushings that are 1/64" proud of the strut. The 4-40 screws will tightened so that the bushing is stationary pinched between the plates.

While I was at it I decided to do the same to the control arms. These will get a 3/16" bushing, again proud so that the screws will tighten down. While in the mill, the ends were skim cut to correct misalignment when built, took about .010" on one side and .004"on the opposite side to clean up. In hind site, it would have been better to put the flats on the end after it was silver brazed. I didn't have the ER32 collet set and four sided collet block at that time which makes setup much easier.

Back to work on my daughter's bathroom today, installing cement board, have all the wallboard up and ready to finish. The PEX pipe makes the water hookup very easy however I had trouble the the 1/2" NPT joints. Originally used pipe compound from Lowe's, very thick and it appears that the threads just pushed it out of the way. Went back used used Teflon tape. That caused several days of delay getting a good leak check.

I had trouble on the chrome nipples to the PEX teardrop fittings and the shower valve to the PEX fittings so I can only assume the problem lies with the PEX fittings.

While I was at it I decided to do the same to the control arms. These will get a 3/16" bushing, again proud so that the screws will tighten down. While in the mill, the ends were skim cut to correct misalignment when built, took about .010" on one side and .004"on the opposite side to clean up. In hind site, it would have been better to put the flats on the end after it was silver brazed. I didn't have the ER32 collet set and four sided collet block at that time which makes setup much easier.

Back to work on my daughter's bathroom today, installing cement board, have all the wallboard up and ready to finish. The PEX pipe makes the water hookup very easy however I had trouble the the 1/2" NPT joints. Originally used pipe compound from Lowe's, very thick and it appears that the threads just pushed it out of the way. Went back used used Teflon tape. That caused several days of delay getting a good leak check.

I had trouble on the chrome nipples to the PEX teardrop fittings and the shower valve to the PEX fittings so I can only assume the problem lies with the PEX fittings.

TonyHallo

640cc Uber Pimp

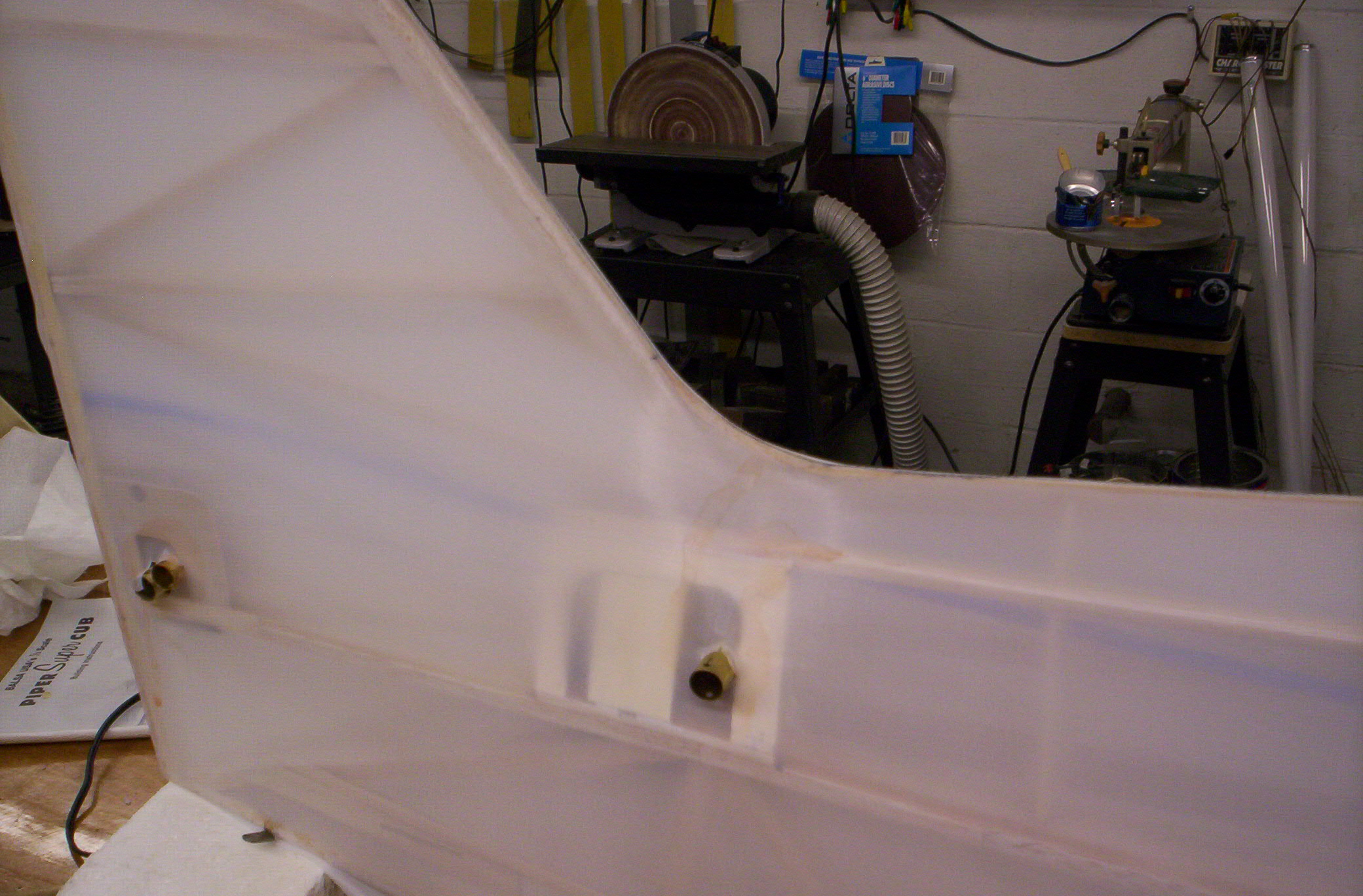

I have covered three planes with fabric. Without a doubt the most difficult area is the transition between the vertical fin and the fuselage. You really can't stretch fabric like Monokote. When putting on the finishing tape it's really tough using the precut F&M tape since it is cut straight with the fabric threads. When covering the plane originally I bet I pulled the tape off three times before I was satisfied. I did the same on the Super Cub I built some time ago. On full scale airplanes bias cut tape is used in the these areas since the fabric is cut on a 45 degree angle with the cords which allows the tape to flow. Pinked bias cut tape is not available from F&M for models. The 3 mm pinking shears now make this possible.

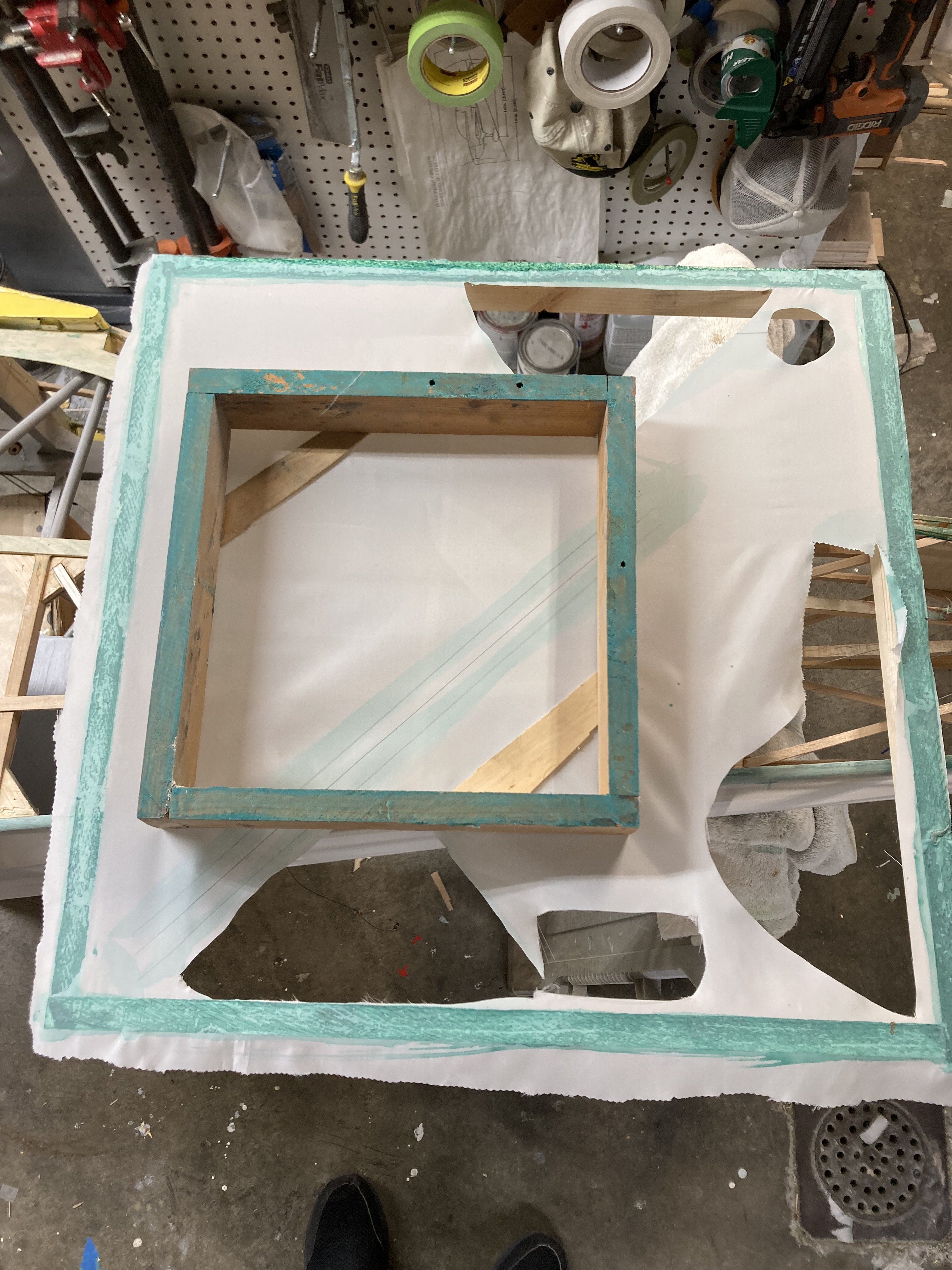

For making patches and such out of fabric, the fabric is pre-shrunk to 250 degrees before cutting and installing. The frame I used in the past is sitting on top of the larger frame since now I need to make longer cutouts. You can see I have the finish tape laid out. I have found the pinked edges come out much better if I cover the cutline with glue and allow it to dry, it locks in the small pieces of thread. Brush the Ekobond glue on and wipe it off with a paper towel, let it dry and then cut. If using Stits, Poly Brush would be used.

For making patches and such out of fabric, the fabric is pre-shrunk to 250 degrees before cutting and installing. The frame I used in the past is sitting on top of the larger frame since now I need to make longer cutouts. You can see I have the finish tape laid out. I have found the pinked edges come out much better if I cover the cutline with glue and allow it to dry, it locks in the small pieces of thread. Brush the Ekobond glue on and wipe it off with a paper towel, let it dry and then cut. If using Stits, Poly Brush would be used.

Stevendavis

100cc

Hey Tony,

Did you cover just the tail on purpose? I've alway tried to use one full length piece on each side and overlap at the top. Is it easier to do just the tail section first?

Did you cover just the tail on purpose? I've alway tried to use one full length piece on each side and overlap at the top. Is it easier to do just the tail section first?

TonyHallo

640cc Uber Pimp

I'm using the blanket method and the Champ lacks a center stringer so it works out better to do the tail separate. Notice in the photo how the leading edge of the rudder just disappears into the space between the two top stringers. The sides and the top are simple to do, there's more work in the tail getting it to blend nicely into the fuselage. The Piper Cub has a center stringer so that makes doing the side and vertical fin together easier.

When I built the Super Cub I used the envelope method. The sides were marked, sewed together and installed in one piece as it is done on full scale.

When I built the Super Cub I used the envelope method. The sides were marked, sewed together and installed in one piece as it is done on full scale.