TonyHallo

640cc Uber Pimp

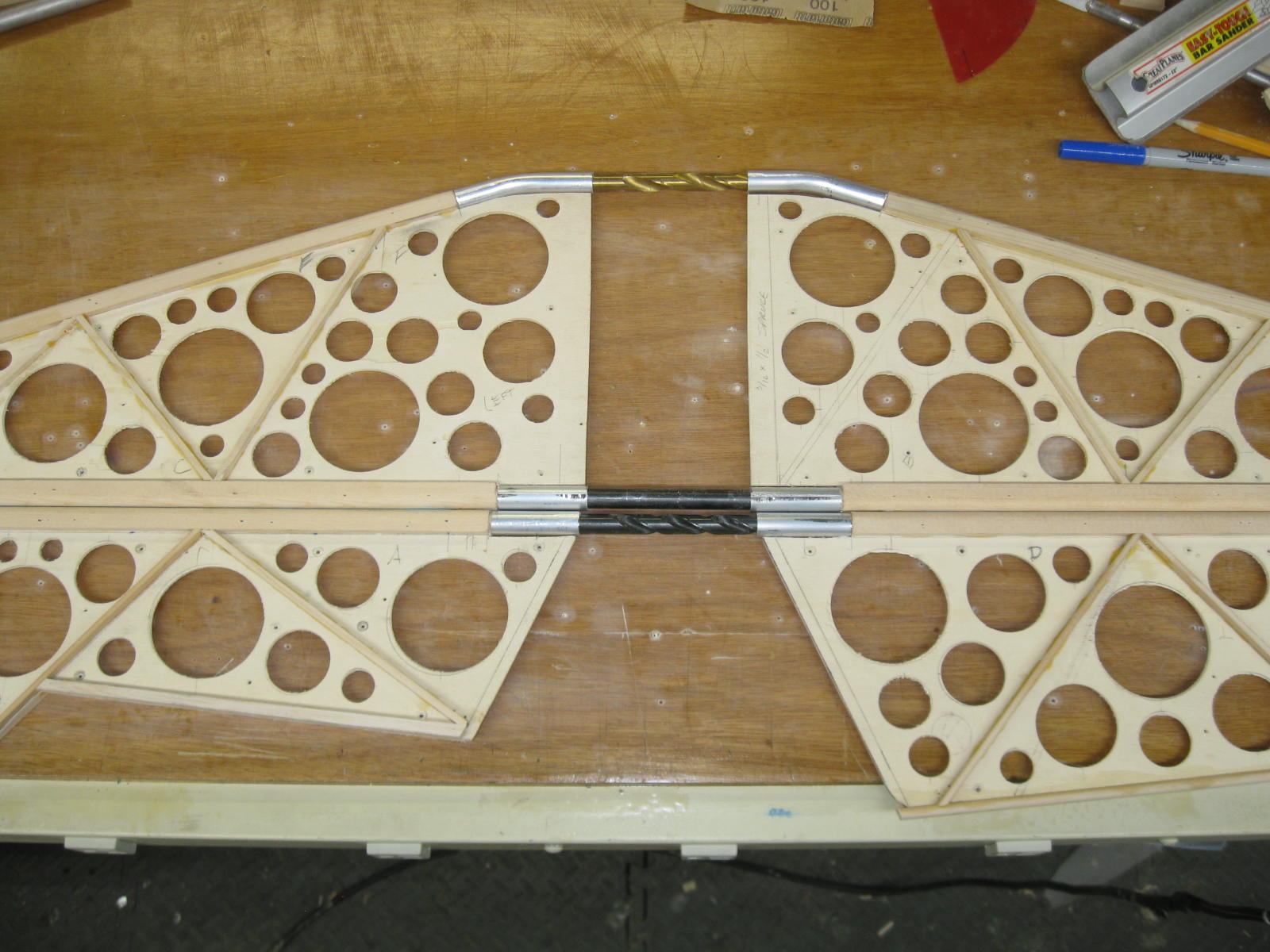

It was nine days since I last cut the grass due to rain, spent good part of the day tending to the grass, two passes. Did manage to get the joiner tubes fit onto the stab and elevator. Before the tubes are glued in place I want to have the holes drilled for the attachment bolting. Need to turn some aluminum stock down to the ID of joiner tubes for the stabilizer and steel for the elevator, (using steel on the elevator so that the control horn can be silver brazed on), then drill the tubes together. Before moving forward, need to reconfigure the lathe, the compound is currently installed and compounds on Harbor Freight 9x19 lathes are not the best.