Working on firewall installation....and it's coming along more easily than I thought! Basically, the fuselage has a flat surface that is the identical diameter to the spinner provided with the plane...and that surface includes the right thrust angle required already built in so that the spinner will meet the front of the fuse perfectly.

So I've taken that flat, round surface as my datum (reference surface) and will build backwards to get the firewall placed in the fuselage. I placed 1/8" spacers between the spinner backplate and the fuse, and then taped the backplate in place aligned to the fuse, with the engine hanging off the spinner backplate inside the aircraft.

First step was to drill the hole for carb clearance...this aligned perfectly with the small; pilot provided in the firewall..building confidence that I was doing right...

Once that clearance hole was in I was able to move the firewall into position...while there is no reference for where the firewall fits, there is a logical place where it snugly mates to the entire surrounding fuselage sides...so that is where it will be...and will require 1/2" of spacers between the fuse and firewall...working on those next!

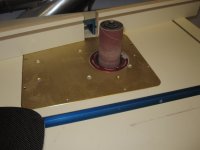

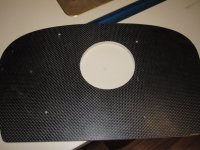

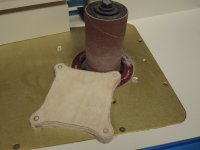

View attachment 10022 View attachment 10023 View attachment 10024 View attachment 10025 View attachment 10026 View attachment 10027 View attachment 10028 View attachment 10029 View attachment 10030