You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

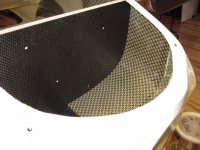

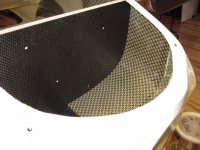

IMAC Delro 2.5M Raven Build

- Thread starter Wacobipe

- Start date

Wacobipe

100cc

I need some advice from all the composite experts out there...

The firewall fits nicely within the fuse, but there is no reference and a fair degree of freedom for placement, and I am not sure how to mock the firewall/engine/fuse up to determine where it belongs.

The nose of the airplane where it meets the spinner has built in several degrees of right torque compensation...so I know exactly where I want the spinner to be....and I can mock everything else behind that off the nose surface where it meets the spinner...

I feel like I need to get the engine floating in space in the nose of the airplane located in the right position as dictated by the nose of the airplane, then clearance the firewall for the carb inlet, and finally mark the engine mount locations...but getting all that mocked up inside the airplane has me a bit stumped. I guess I can just start cutting spacers and supports out of wood and wedging the engine in place until it fits and is secured, then work the firewall into place...but I think there may be a better way.

How about it @Terryscustom, @Pistolera, @Jlc, @IMAC FANATIC ?

There's a clever method out there somewhere...I just need pointed in the right direction!

The firewall fits nicely within the fuse, but there is no reference and a fair degree of freedom for placement, and I am not sure how to mock the firewall/engine/fuse up to determine where it belongs.

The nose of the airplane where it meets the spinner has built in several degrees of right torque compensation...so I know exactly where I want the spinner to be....and I can mock everything else behind that off the nose surface where it meets the spinner...

I feel like I need to get the engine floating in space in the nose of the airplane located in the right position as dictated by the nose of the airplane, then clearance the firewall for the carb inlet, and finally mark the engine mount locations...but getting all that mocked up inside the airplane has me a bit stumped. I guess I can just start cutting spacers and supports out of wood and wedging the engine in place until it fits and is secured, then work the firewall into place...but I think there may be a better way.

How about it @Terryscustom, @Pistolera, @Jlc, @IMAC FANATIC ?

There's a clever method out there somewhere...I just need pointed in the right direction!

Pistolera

HEY!..GET OUTTA MY TREE!

Put some padding on the floor and stand the fuse on its tail. Strap it against something, like a basement post, fridge, etc. Once secured you can carefully sit the engine on its mount and slide it around so you get you spinner centered on the cowl ring. Slide your spinner backplate on to check it. Then mark it, triple check and drill.

IMAC FANATIC

40% happier than most folks.

There ya go easy peazy,

measure out the difference and make a spacer if necessary to keep it tight. Dont forget to put down thrust spacers/washers in if you intend to use them to keep it purdy.

measure out the difference and make a spacer if necessary to keep it tight. Dont forget to put down thrust spacers/washers in if you intend to use them to keep it purdy.

Jetpainter

640cc Uber Pimp

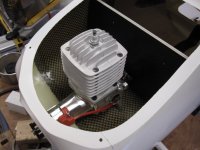

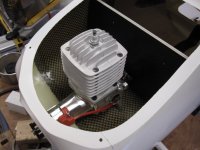

Are you planning on bolting the engine straight to the firewall without spacers? I know the 85 doesn't like standoffs from what Ive been told.

I guess if you pull the carb off you can lay the engine right on the firewall and using Earl's suggestions get it aligned and marked.

You'll also need make some provisions for the needle valves. Their location makes their access when the engine is mounted to the firewall tricky at best, but I'm sure you ran into that on the 60 in your Pitts.

I guess if you pull the carb off you can lay the engine right on the firewall and using Earl's suggestions get it aligned and marked.

You'll also need make some provisions for the needle valves. Their location makes their access when the engine is mounted to the firewall tricky at best, but I'm sure you ran into that on the 60 in your Pitts.

Wacobipe

100cc

Mine has tiny holes drilled...but they don't come close to matching the DA85 bolt pattern anyway...My firewall is already drilled so I'm going to stand mine on its tail and put the spinner backplate on and get the gap even all the way around and epoxy it in. Would be easier with an extra set of hands. GLAD you back!!!

Wacobipe

100cc

Direct to firewall would be ideal...and it could work in this case...but I am not sure I can get the engine in/out once I epoxy the firewall in if I do This (without removing the carb first)... And that seems like a pain in the a$$! I am going to mock things up first so I will try to see if I can make that work.Are you planning on bolting the engine straight to the firewall without spacers? I know the 85 doesn't like standoffs from what Ive been told.

I guess if you pull the carb off you can lay the engine right on the firewall and using Earl's suggestions get it aligned and marked.

You'll also need make some provisions for the needle valves. Their location makes their access when the engine is mounted to the firewall tricky at best, but I'm sure you ran into that on the 60 in your Pitts.

If I can't mount direct to firewall, then I will be using plywood spacers...not stand offs. The 85 is one big cylinder of pure torque so I think it needs all the support it can get!