gyro

GSN Contributor

Alright, time to start!

This build log is obviously for the new 3DHS 92" Edge 540, 50/60cc airplane. For our setup, we're going with the following items:

Engine: GP 61cc from www.limitlessaero.com

Servos: HS-9370TH Brushless, Titanium, HV servos from www.hitecrcd.com

Bling: Fuel Dot, Servo Arms, Pull-Pull turnbuckles from www.aztechaeromodels.com

Power: Glacier 2200mAh 2s LiPo Batteries from www.buddyrc.com

Control: Spektrum AR9110 DSMX Power Safe Reciever

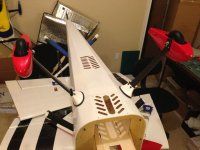

Here is the ARF kit spread out:

As usual, the covering is well applied, and looks great! Not even a wrinkle to fix

Unpacked the accessories bag, there is a lot to sort through:

Got the fuse on my build stand, and took a minute to admire the fast lines of the fuse design, and peak inside the fuse and canister tunnel:

I noticed immediately how easy it'll be to access the landing gear bolts to tighten them down.

This build log is obviously for the new 3DHS 92" Edge 540, 50/60cc airplane. For our setup, we're going with the following items:

Engine: GP 61cc from www.limitlessaero.com

Servos: HS-9370TH Brushless, Titanium, HV servos from www.hitecrcd.com

Bling: Fuel Dot, Servo Arms, Pull-Pull turnbuckles from www.aztechaeromodels.com

Power: Glacier 2200mAh 2s LiPo Batteries from www.buddyrc.com

Control: Spektrum AR9110 DSMX Power Safe Reciever

Here is the ARF kit spread out:

As usual, the covering is well applied, and looks great! Not even a wrinkle to fix

Unpacked the accessories bag, there is a lot to sort through:

Got the fuse on my build stand, and took a minute to admire the fast lines of the fuse design, and peak inside the fuse and canister tunnel:

I noticed immediately how easy it'll be to access the landing gear bolts to tighten them down.