You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC The new Dalton 300 SP / 330

- Thread starter orthobird

- Start date

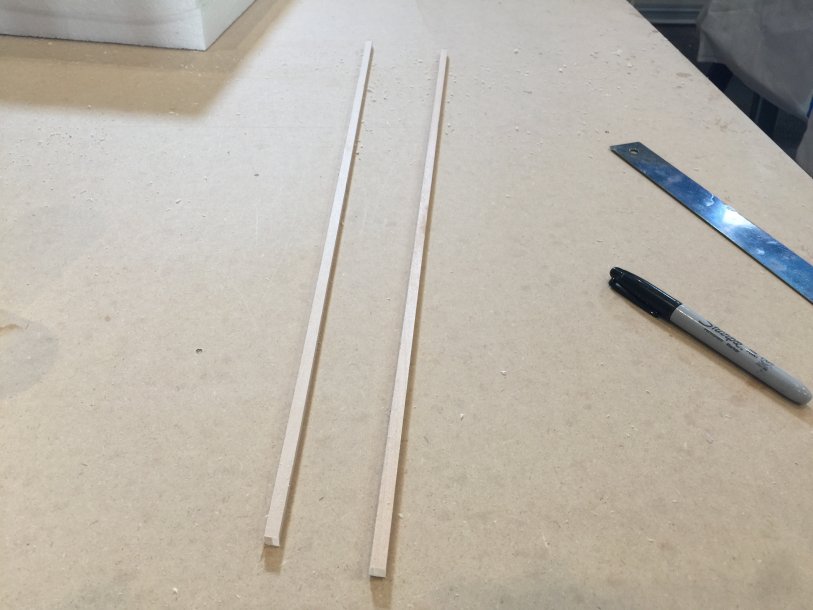

Getting almost ready to sheet the wings, and I compromised. What I have done is a compromise. Instead of using carbon fiber, I went with spruce, and instead of going from the root to the tip, i centered a 24 " segment around the tip of the wing tube. total weight addition will be 1 ounce for the top and bottom. Not bad. Had I gone with carbon fiber, penalty is 4 ounces.

I used the router with the 1/4" router bit.

I then used the spruce, 24" length, and placed them on top and bottom to strengthen the end of the wing tube further. No need to go to the tip or the root.

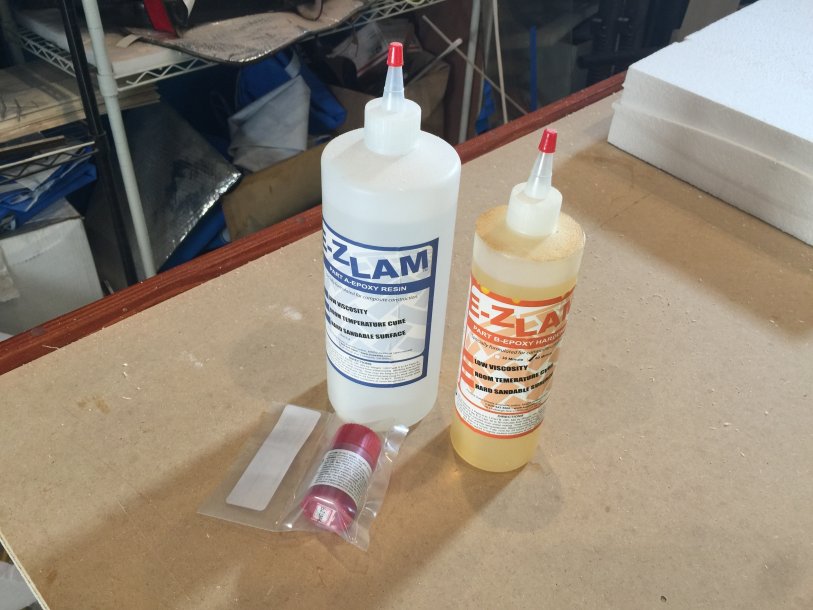

this will be my epoxy resin to use, from ACP. I will also apply a small amount of red dye, so that I can visualize where the glue has been placed.

Some cool data.

As of now, the weight of the wings are

with root caps on, phenolic, balsa and spruce support

right wing weighs 21.625 ounces = 1.35 pounds

left wing weighs 22.225 ounces = 1.39 pounds

after I sheet it, I will re-weigh them, and be sure to report back to you all.

I used the router with the 1/4" router bit.

I then used the spruce, 24" length, and placed them on top and bottom to strengthen the end of the wing tube further. No need to go to the tip or the root.

this will be my epoxy resin to use, from ACP. I will also apply a small amount of red dye, so that I can visualize where the glue has been placed.

Some cool data.

As of now, the weight of the wings are

with root caps on, phenolic, balsa and spruce support

right wing weighs 21.625 ounces = 1.35 pounds

left wing weighs 22.225 ounces = 1.39 pounds

after I sheet it, I will re-weigh them, and be sure to report back to you all.

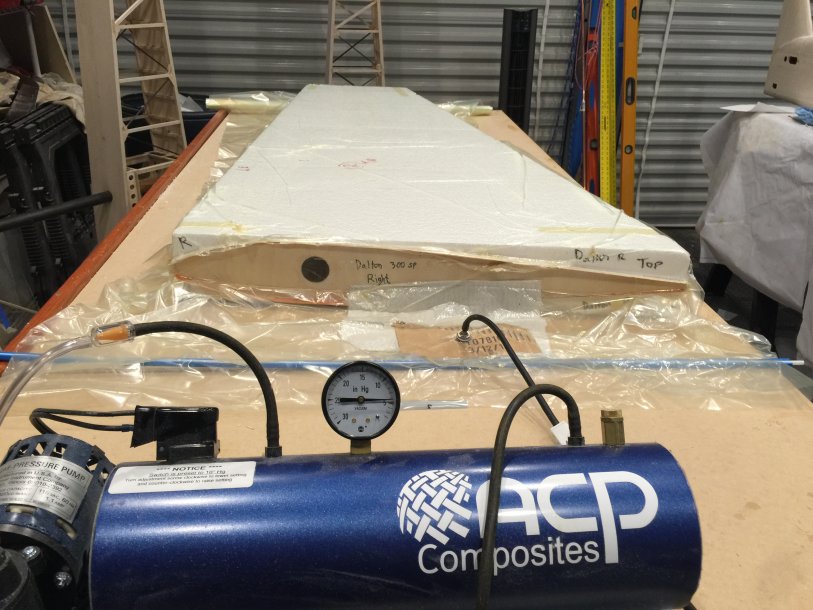

Just did the 1st wing. (right wing). Was able to use 3 ounces of measured epoxy resin per side. At first, I was very worried, because it seemed it would not be enough, but by the end, it seemed like more than plenty. I am certain I could do it with 2.5 ounces per side.

SO far, this is looking good, the right wing has a total of 6 ounces of epoxy resin. It will be interesting to see how much it weighs when it is said and done.

this is 3 ounces spread over the bottom sheet

I have the pressure set between 5 and 7 mm Hg, meaning, it turns on at 5 and when it reaches 7, it stops pumping.

I did make some measurements of before and after:

the brush, before i used it, weighed = 3.88 ounces. After i did the 1st side, I reweighed, and it was 4.30 ounces, so it soaked up .42 ounces

the blue mixing bucket I used to mix the epoxy resin weighed 2.04 ounces, and after using the resin, it weighed 2.18 ounces

therefore, I believe I used only 2.5 ounces, since the remainder was left behind.

Additionally, I weighed the 3 measured ounces with the mixing pail, and it weighed 4.79 ounces (minus 2.04) , means that the 3 measured ounces weighed = 2.75 ounces!

SO far, this is looking good, the right wing has a total of 6 ounces of epoxy resin. It will be interesting to see how much it weighs when it is said and done.

this is 3 ounces spread over the bottom sheet

I have the pressure set between 5 and 7 mm Hg, meaning, it turns on at 5 and when it reaches 7, it stops pumping.

I did make some measurements of before and after:

the brush, before i used it, weighed = 3.88 ounces. After i did the 1st side, I reweighed, and it was 4.30 ounces, so it soaked up .42 ounces

the blue mixing bucket I used to mix the epoxy resin weighed 2.04 ounces, and after using the resin, it weighed 2.18 ounces

therefore, I believe I used only 2.5 ounces, since the remainder was left behind.

Additionally, I weighed the 3 measured ounces with the mixing pail, and it weighed 4.79 ounces (minus 2.04) , means that the 3 measured ounces weighed = 2.75 ounces!

Just finished weighing the right wing, after removing it from the bag system.

Now this wing has:

phenolic tube support, phenolic tube, spar extensions, root ply cap, & top and bottom sheeting

weight is 13.61 ounces at the tip

and 25.25 ounces at the root

total weight so far is 2.42 pounds.

I also had weighed the balsa sheeting before using it and it was 6.17 ounces for the top and 6.01 for the bottom = 12.18 ounces

let's see if it all adds up

21.625 + sheeting 12.18 ounces = 33 ounces, without the glue

total wing weight is 38.7 ounces

38.7 minus 33 ounces = 5.7 ounces

so according to my calculation, the glue weight is 5.7 ounces total, for one wing

so this is very much in line with what I thought, of about 3 ounces per side.

on another build, when I had done this step, using polyurethane glue, and the 48" carbon square rods, the weight was at 2.5 pounds.

So so far, I do not see much of a difference, I am stumped!

the big difference, was, that using the bag technique, i did not do any heavy lifting.

SO makes me wonder, If you use poly-urethane glue, does it "evaporate" to some extent, and lose its water weight as it cures?

I know I had used 6 ounces per side, and thus 12 ounces. SO I would have expected these wings to be much lighter.

This is called a paradigm shift!

Now this wing has:

phenolic tube support, phenolic tube, spar extensions, root ply cap, & top and bottom sheeting

weight is 13.61 ounces at the tip

and 25.25 ounces at the root

total weight so far is 2.42 pounds.

I also had weighed the balsa sheeting before using it and it was 6.17 ounces for the top and 6.01 for the bottom = 12.18 ounces

let's see if it all adds up

21.625 + sheeting 12.18 ounces = 33 ounces, without the glue

total wing weight is 38.7 ounces

38.7 minus 33 ounces = 5.7 ounces

so according to my calculation, the glue weight is 5.7 ounces total, for one wing

so this is very much in line with what I thought, of about 3 ounces per side.

on another build, when I had done this step, using polyurethane glue, and the 48" carbon square rods, the weight was at 2.5 pounds.

So so far, I do not see much of a difference, I am stumped!

the big difference, was, that using the bag technique, i did not do any heavy lifting.

SO makes me wonder, If you use poly-urethane glue, does it "evaporate" to some extent, and lose its water weight as it cures?

I know I had used 6 ounces per side, and thus 12 ounces. SO I would have expected these wings to be much lighter.

This is called a paradigm shift!

Snoopy1

640cc Uber Pimp

You are correct epoxy is what it is, it is a chemical reaction, no drying where as polyurethane thane glue is a drying process and there for difficult to determine the final weight. The best way to figure this out is to put a known weight on a scale wet let it dry completely for a number of days and weigh it again and calulate the difference and then you will know in the future what your final weight will be.

Snoopy1

640cc Uber Pimp

Have to agree with you time wise the poly glue is a lot faster. Have done both if I am doing a wing that I have done before and everything is known would use poly glue. But if it is complicated and difficult epoxy is the one to use gives you time to think and get it right. The other thing with epoxy it has to run all night and if some thing goes wrong your are in trouble.

Making the leading edge for the wings. These are 4" wide balsa, that is 1/2" thick.

I make a scarf joint at 45 degrees, and I am using the Gorilla Wood Glue, wow, so far, it dries clear, and will sand it once cured, and report back on that. My 1st time using the Gorilla Glue Wood bottle.

Also, I just turned the heater on, to raise temp to 85 degrees in the shop. It was about 68 degrees or so, and this is delaying the cure of the ACP epoxy resin. Which I WILL NOT use again! takes too long to cure.

Going to purchase some WEST Epoxy Resin.

tomorrow, I will sand the LE and TE, and then use the wood Gorilla Glue to glue on the LE and TE, and then put both wings back in the bag! Should be cool!

I make a scarf joint at 45 degrees, and I am using the Gorilla Wood Glue, wow, so far, it dries clear, and will sand it once cured, and report back on that. My 1st time using the Gorilla Glue Wood bottle.

Also, I just turned the heater on, to raise temp to 85 degrees in the shop. It was about 68 degrees or so, and this is delaying the cure of the ACP epoxy resin. Which I WILL NOT use again! takes too long to cure.

Going to purchase some WEST Epoxy Resin.

tomorrow, I will sand the LE and TE, and then use the wood Gorilla Glue to glue on the LE and TE, and then put both wings back in the bag! Should be cool!

Cam, did you squeeze off the excess resin before your put the wood onto the foam before putting into the bag? And, why did you not use a piece of ply cut to the planform and set it on top of the foam and then put int9 the vacuum bag?

there was no excess resin that I could see, I really spread it out.

I was informed that, that is not required, to put a ply over the wood to weigh it down. Any ill effect from not doing that? I was told, that it will be equivalent to 3500 pounds sitting on top of the wings, and to make sure the wings were placed on top of a flat surface.