stangflyer

I like 'em "BIG"!

Just like its counterpart, the right wing panel. The left wing panel was just as wrinkled. Again, nothing to be excited about.

I really like the Top Flite sealing iron for many reasons. One I have found that works superb is getting into tight areas that could normally not be reached. Those pesky inboard surfaces of a pre-installed control surface. (Aileron, Elevator and Rudder) Counter balances. It works terrific on sealing covering back down in the hinge line too.

It took me about an hour on the left wing panel. Other than a small mishap, it turned out really well. Mishap you ask? Weeell.... what a dumb I was. Ugh!!! So I am just coasting along and somehow....I don't know how, I bumped the knob on my iron to the full hottest setting and before I realized it, I over heated a seam where the gold meets the red with a black checker over the top. Yup...you guessed it. Pulled that sucker apart faster than a yolk spilling from a broken egg. Grrrr!!!

I was. Ugh!!! So I am just coasting along and somehow....I don't know how, I bumped the knob on my iron to the full hottest setting and before I realized it, I over heated a seam where the gold meets the red with a black checker over the top. Yup...you guessed it. Pulled that sucker apart faster than a yolk spilling from a broken egg. Grrrr!!!

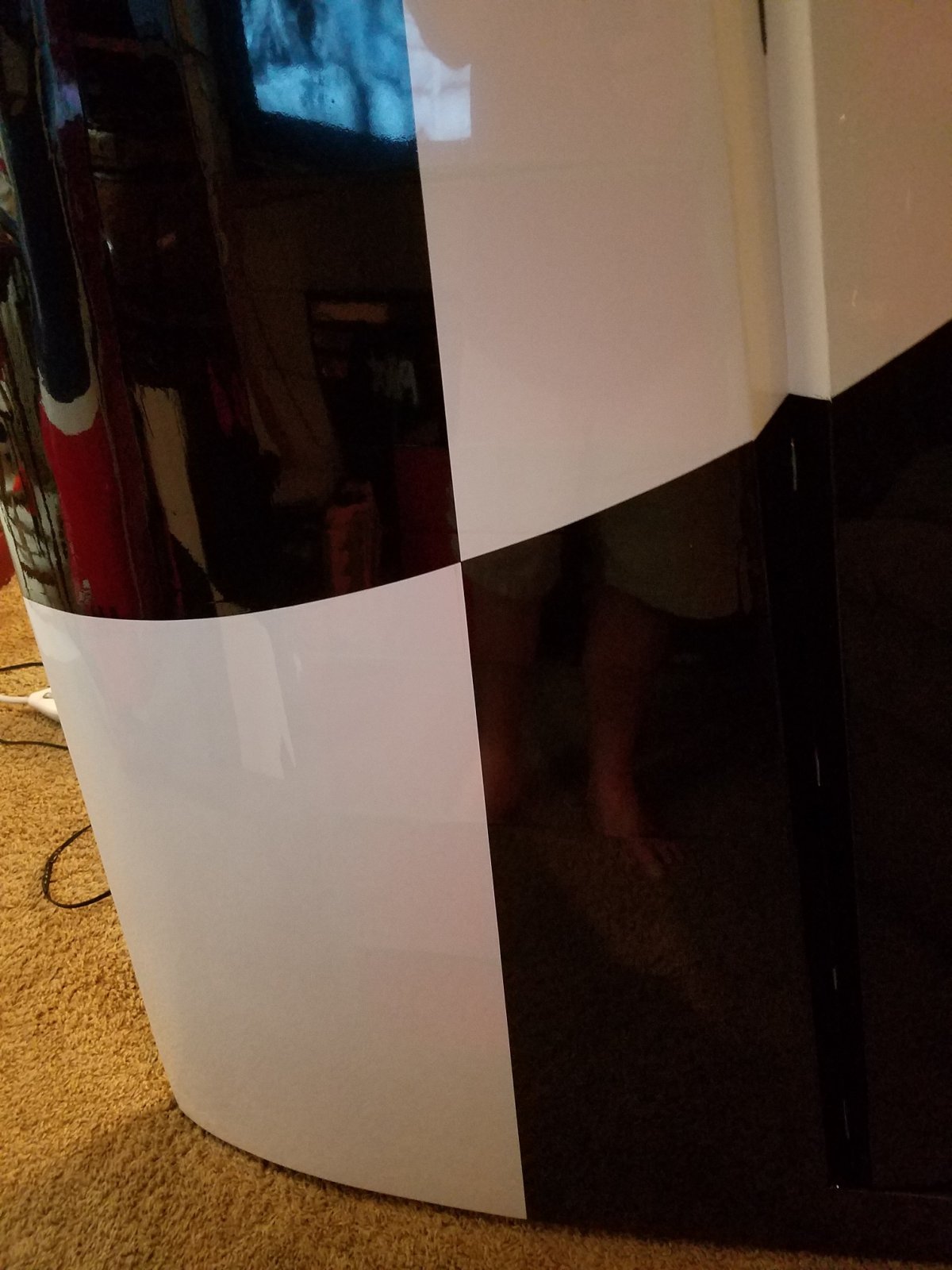

Ah heck, I can fix that. Fortunately I was able to retrieve enough gold to get a small section placed back in. Then recut the black checker that warped and distorted from the excessive heat and wa-laa. Fixed. Unless a trained eye is looking for it, it can't be seen. (Even up close) I hate it when things like this happen. Note to self: (and everyone else) Keep a constant eye on your knobs. LOL. The wing panel turned out pretty nice all in all.

Ah heck, I can fix that. Fortunately I was able to retrieve enough gold to get a small section placed back in. Then recut the black checker that warped and distorted from the excessive heat and wa-laa. Fixed. Unless a trained eye is looking for it, it can't be seen. (Even up close) I hate it when things like this happen. Note to self: (and everyone else) Keep a constant eye on your knobs. LOL. The wing panel turned out pretty nice all in all.

And finally, the last of the shrinking. The Fuse. Yay......

I really like the Top Flite sealing iron for many reasons. One I have found that works superb is getting into tight areas that could normally not be reached. Those pesky inboard surfaces of a pre-installed control surface. (Aileron, Elevator and Rudder) Counter balances. It works terrific on sealing covering back down in the hinge line too.

It took me about an hour on the left wing panel. Other than a small mishap, it turned out really well. Mishap you ask? Weeell.... what a dumb

I was. Ugh!!! So I am just coasting along and somehow....I don't know how, I bumped the knob on my iron to the full hottest setting and before I realized it, I over heated a seam where the gold meets the red with a black checker over the top. Yup...you guessed it. Pulled that sucker apart faster than a yolk spilling from a broken egg. Grrrr!!!

I was. Ugh!!! So I am just coasting along and somehow....I don't know how, I bumped the knob on my iron to the full hottest setting and before I realized it, I over heated a seam where the gold meets the red with a black checker over the top. Yup...you guessed it. Pulled that sucker apart faster than a yolk spilling from a broken egg. Grrrr!!!And finally, the last of the shrinking. The Fuse. Yay......

Last edited: