You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GSN GIVE-A-WAY Hangar 9 35% Extra 300X Assembly

- Thread starter Jetpainter

- Start date

Jetpainter

640cc Uber Pimp

Yes it is. I had them several ways, totally open like a Carf, Somewhat open on top and bottom like an Aeroworks, or all enclosed like my Pilot Edge. The only thing I don't like about this one is the way they have it setup to vent out the bottom. It's just a massive hole your supposed to cut open in the covering that's probably 5" by 10". I'm sure its very functional, but it's butt ugly. I'm going to need to do something about it.Is the pipe tunnel open to the rest of the fuse???

BalsaDust

Moderator

Will you be closing off the sides of the tunnel. I have a header and canister for my PAU Sukhoi that I need to install but have been holding off as I was thinking it would be best close the tunnel up. Just didn't know how much heat it would stop from getting to the inside of the fuse if I closed it off.

Jetpainter

640cc Uber Pimp

The side are closed to pretty much where the canisters stop and I'm planning on leaving it just the way it is.Will you be closing off the sides of the tunnel. I have a header and canister for my PAU Sukhoi that I need to install but have been holding off as I was thinking it would be best close the tunnel up. Just didn't know how much heat it would stop from getting to the inside of the fuse if I closed it off.

On my scratch build enclosed the tuned except the top towards the back. Where the rudder servo mounts it would have been very tough to close it in, and in the radio area I had cut lightening holes in it before thinking about enclosing the pipe. I'm planning on removing the hatch after every flight to let it cool off. I've only got one flight on it so far, but it wasn't hot at all inside when I took the hatch off. My fuel dot in under the hatch so I need to take it off anyway between flights.

As you can see by these pics, there is a lot of pipe to keep cool on "Miss Moana" for a 50cc airplane.

Jetpainter

640cc Uber Pimp

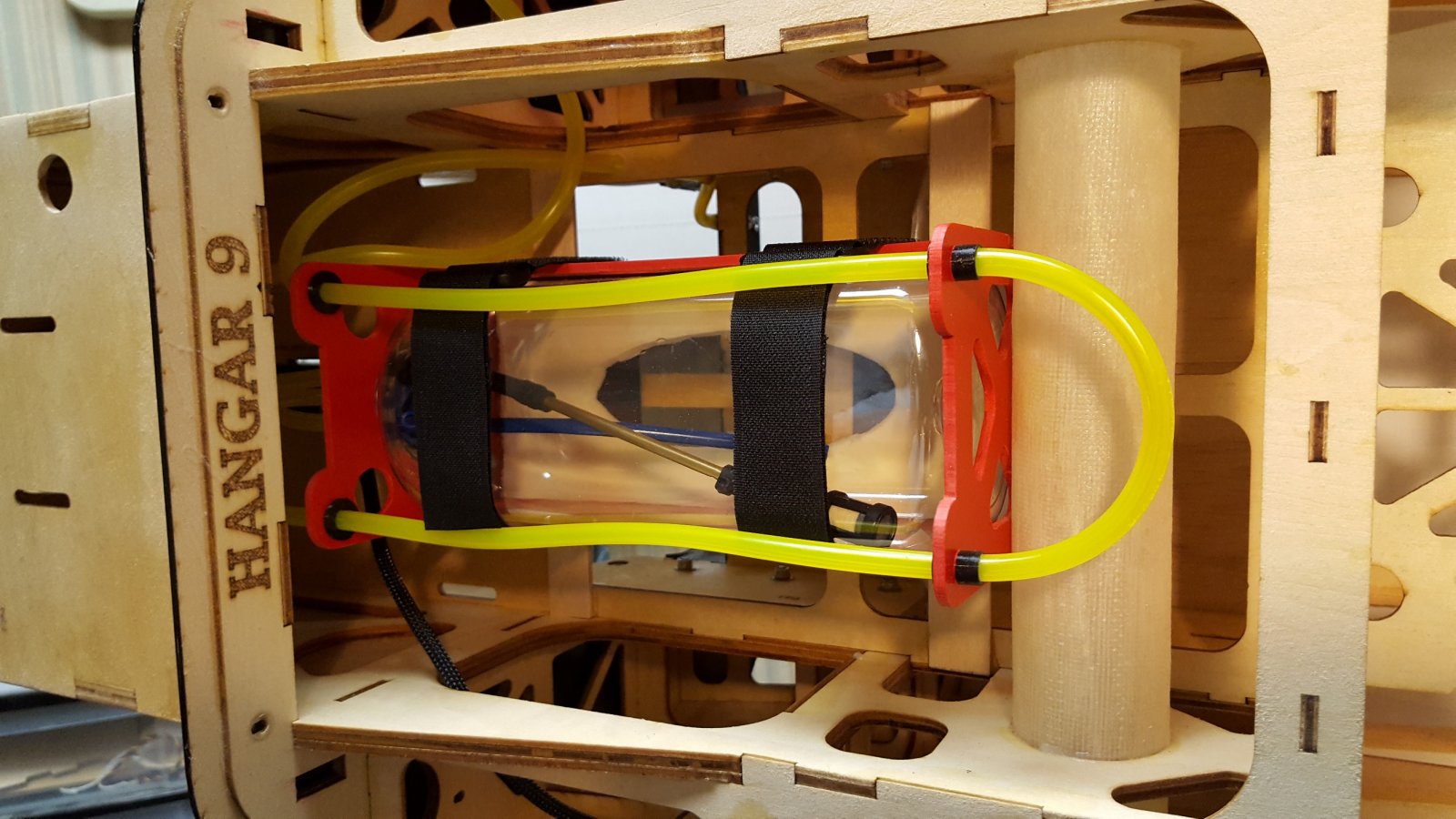

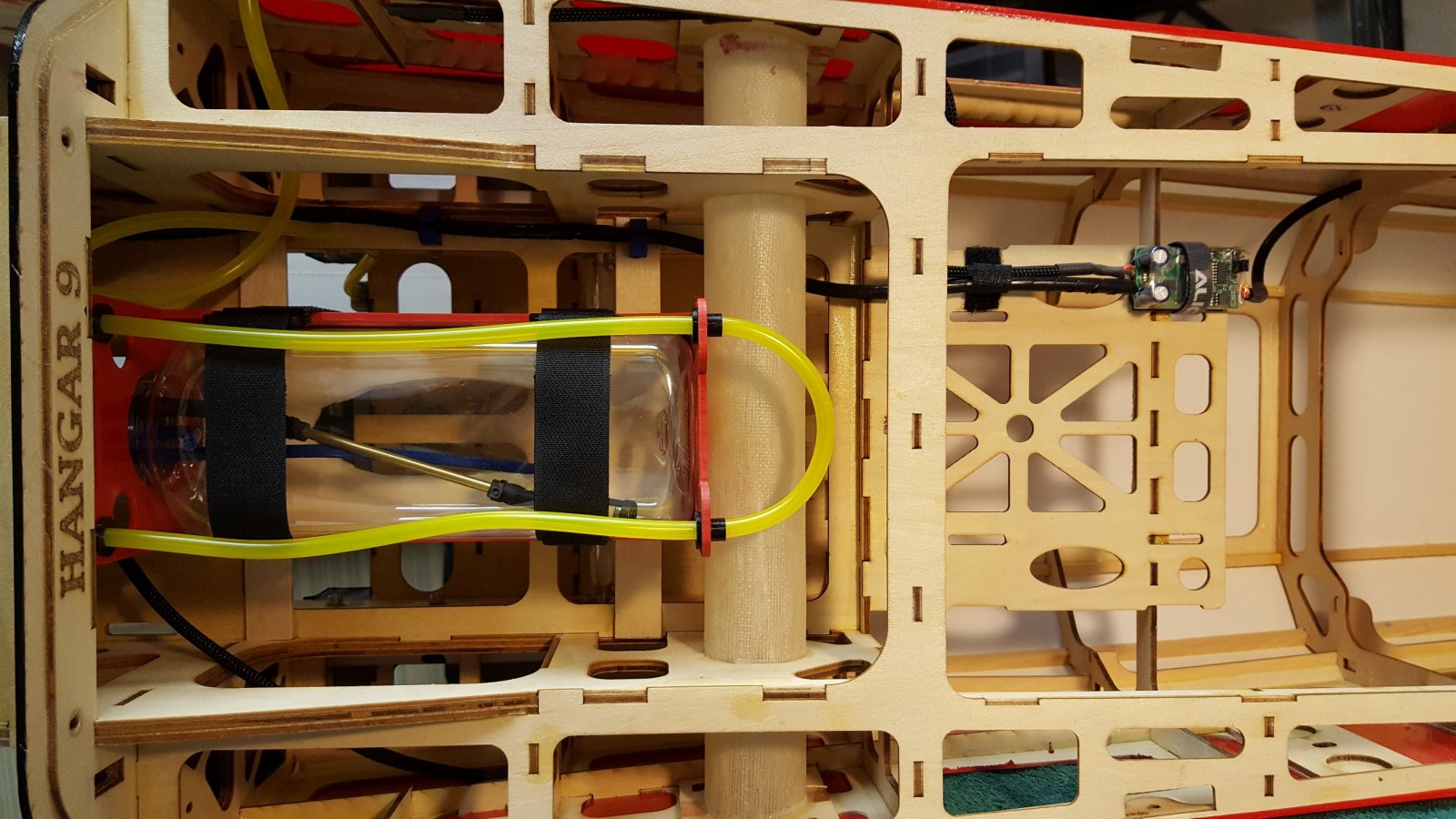

I worked on the fuel system last night. I didn't expect it to eat up my whole night and not be finished, but I guess I should have known better.

I realized life would be easier if I would finish installing the homemade canister mount before the fuel tank mount. The canister mount still needed to be deburred and smoothed out before it was installed for good. So, a file, some sandpaper, and a wire wheel in Dremel took care of that. The canister mount is in for good now I hope.

I mounted the fuel tank bracket and routed all the lines where they need to be. It took some time trying to figure out where the vent tube exit was going to go. As much as I like running canisters, sometimes the canister tunnel makes running the vent tube a pain. I decided to make a small aluminum bracket and use a fuel tank fitting for the exit. I then had to make a brass strap to hold the Tygon where is passes through the tunnel so it wouldn't touch the canisters.

All I need to do now is plug all the lines into the tank and strap it down.

I realized life would be easier if I would finish installing the homemade canister mount before the fuel tank mount. The canister mount still needed to be deburred and smoothed out before it was installed for good. So, a file, some sandpaper, and a wire wheel in Dremel took care of that. The canister mount is in for good now I hope.

I mounted the fuel tank bracket and routed all the lines where they need to be. It took some time trying to figure out where the vent tube exit was going to go. As much as I like running canisters, sometimes the canister tunnel makes running the vent tube a pain. I decided to make a small aluminum bracket and use a fuel tank fitting for the exit. I then had to make a brass strap to hold the Tygon where is passes through the tunnel so it wouldn't touch the canisters.

All I need to do now is plug all the lines into the tank and strap it down.

Alky6

150cc

Will you be closing off the sides of the tunnel. I have a header and canister for my PAU Sukhoi that I need to install but have been holding off as I was thinking it would be best close the tunnel up. Just didn't know how much heat it would stop from getting to the inside of the fuse if I closed it off.

On my JTEC 35% the tunnel is open on the sides. I only put a 3/32 balsa sheet between the pipes and the fuel tank. No issues.

Jetpainter

640cc Uber Pimp

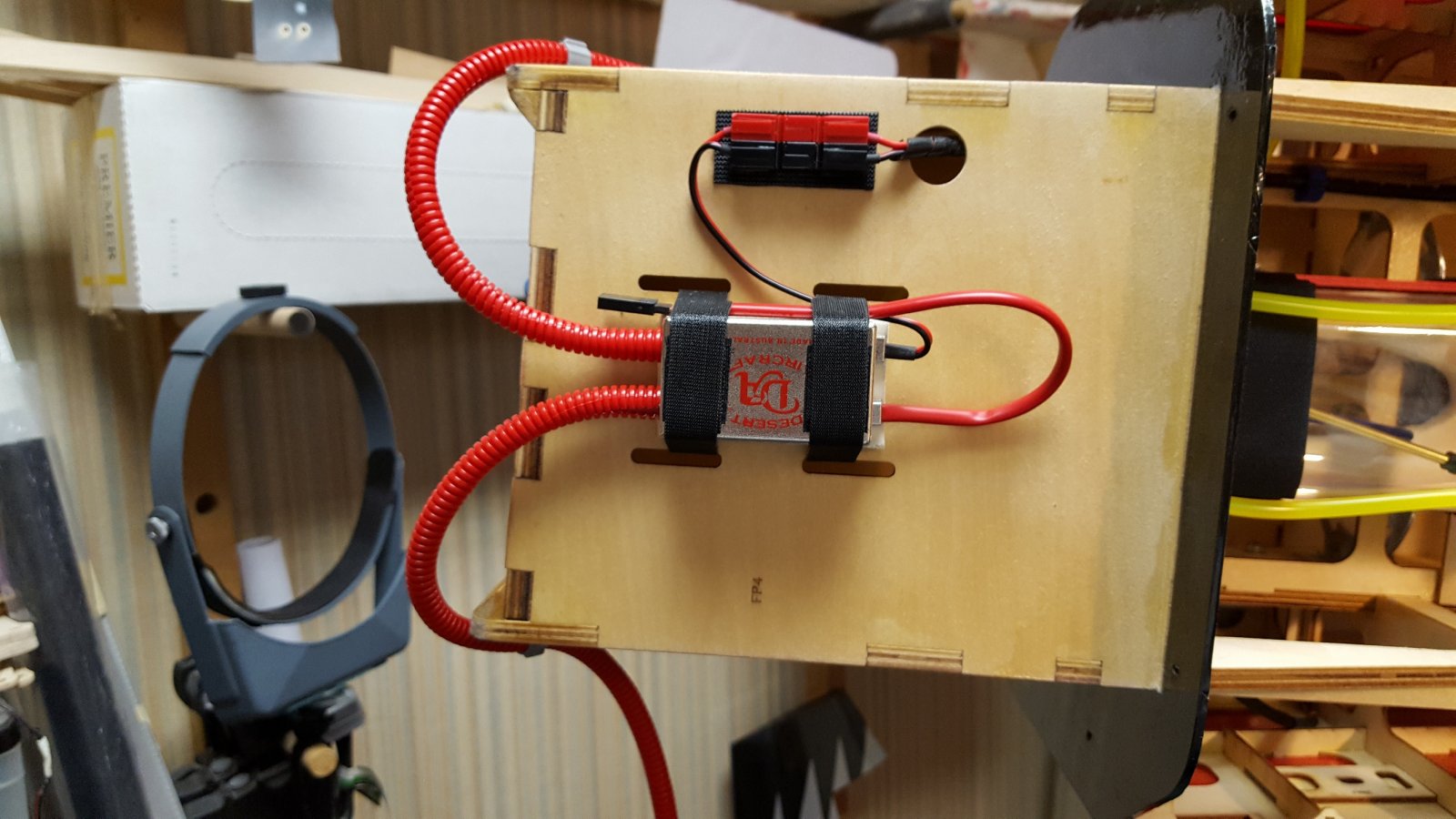

Last night I finished the fuel system and installed the Tech-Aero Ultra IBEC. I'm still waiting for some extentions before I can plug the IBEC into the receiver, and finish the throttle servo. They may show up today. Tonight I'll probably work on the aileron wiring.

Jetpainter

640cc Uber Pimp

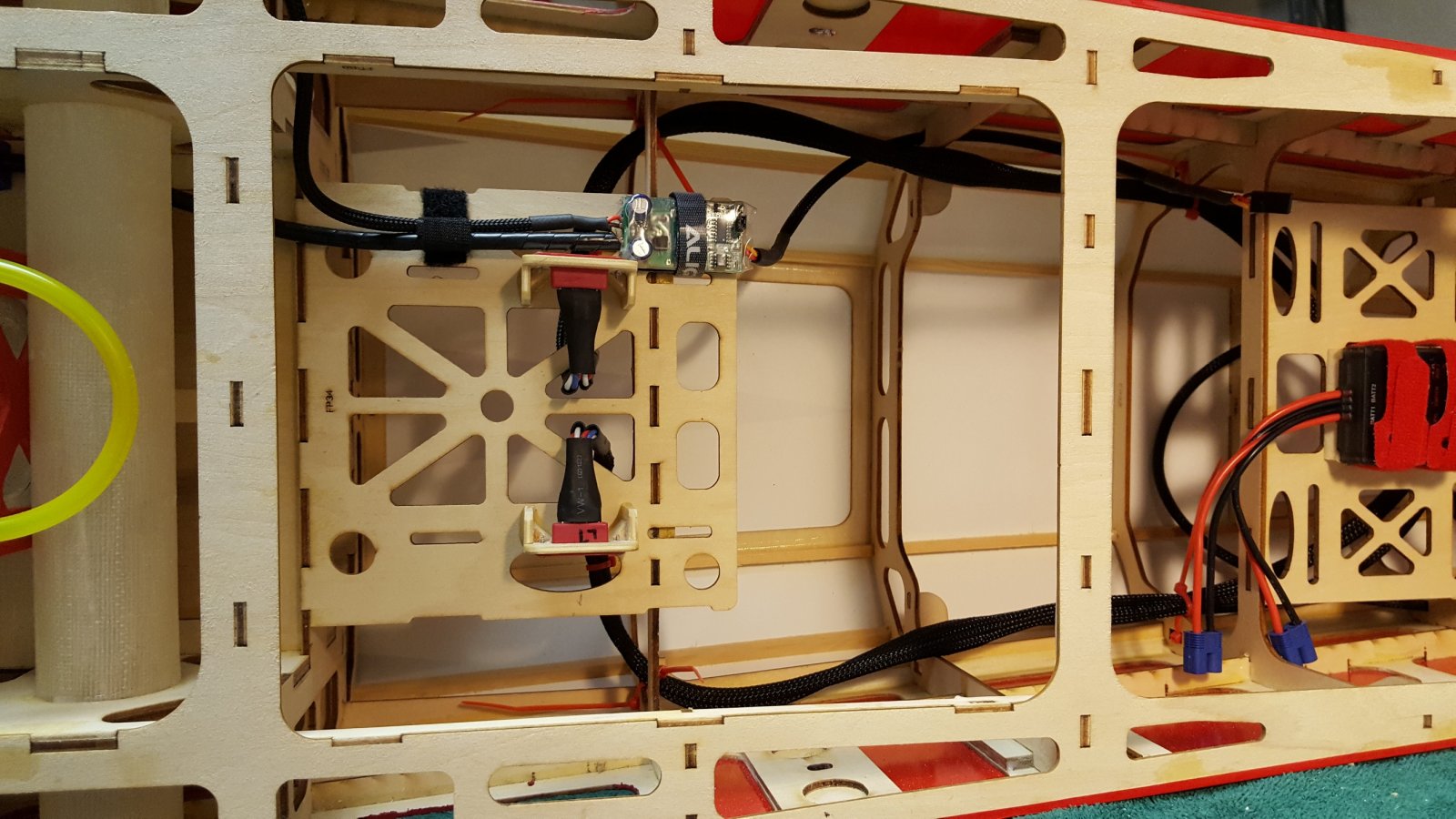

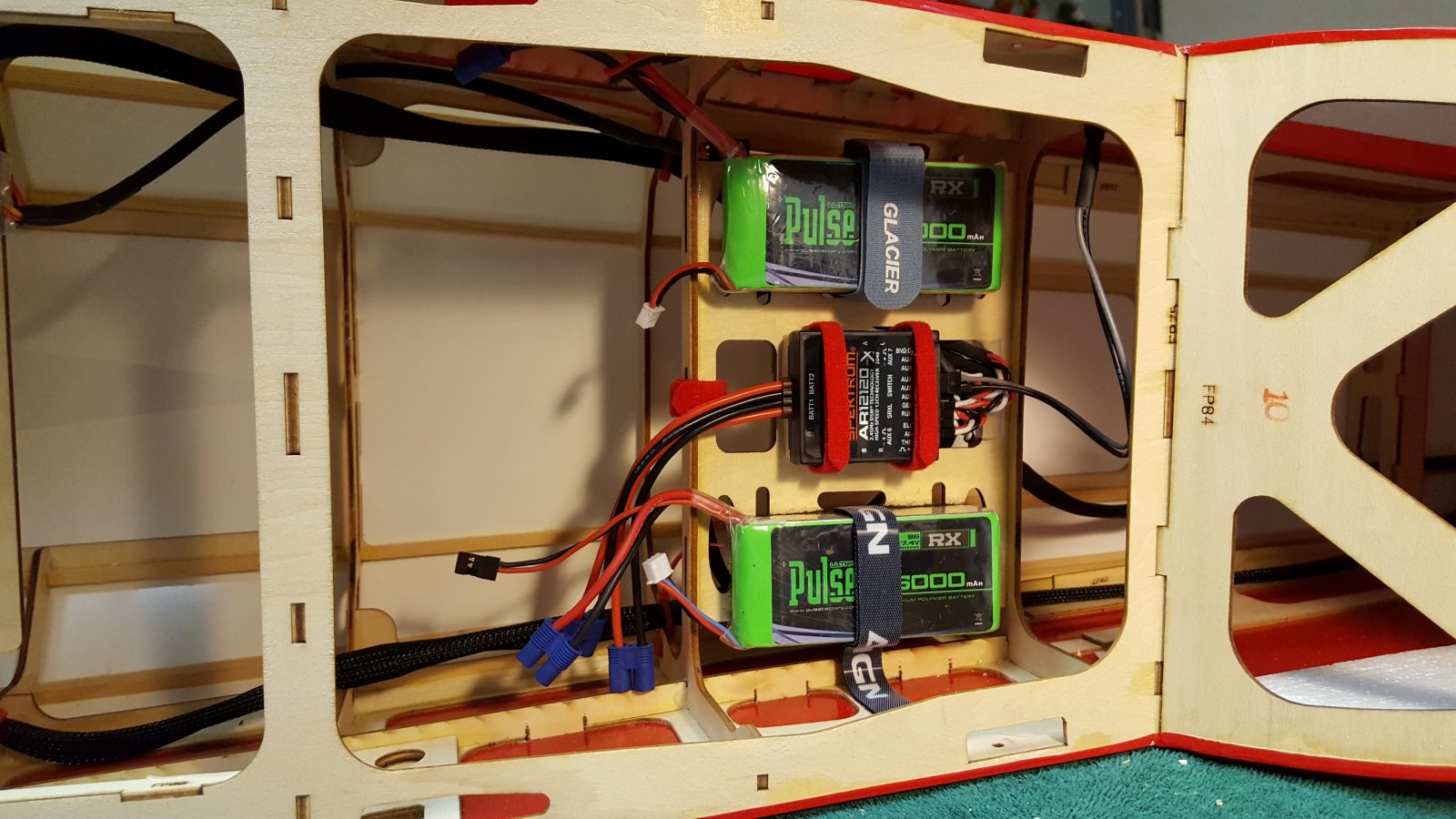

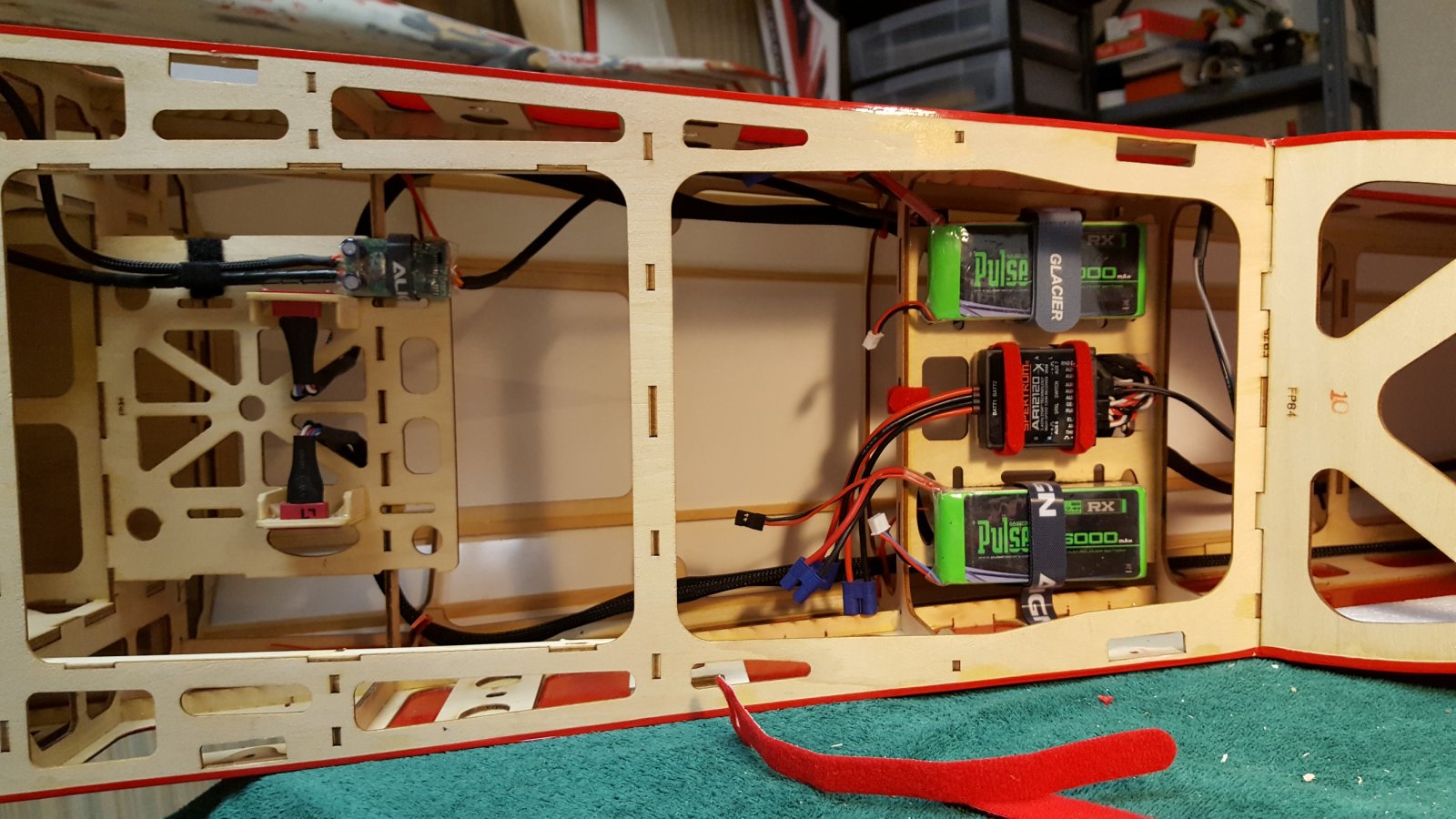

After my disappointing day at the field with Miss Moana I came home and worked on the Extra. Last night I had worked on finishing up the ignition install and built some brackets to mount the Taildragger aileron harness plugs. This afternoon I installed the harnesses and test fitted the batteries. I'm hoping it will balance with the batteries mounted there since they're easy to get in and out there. I do need some different straps.

Last edited:

Jetpainter

640cc Uber Pimp

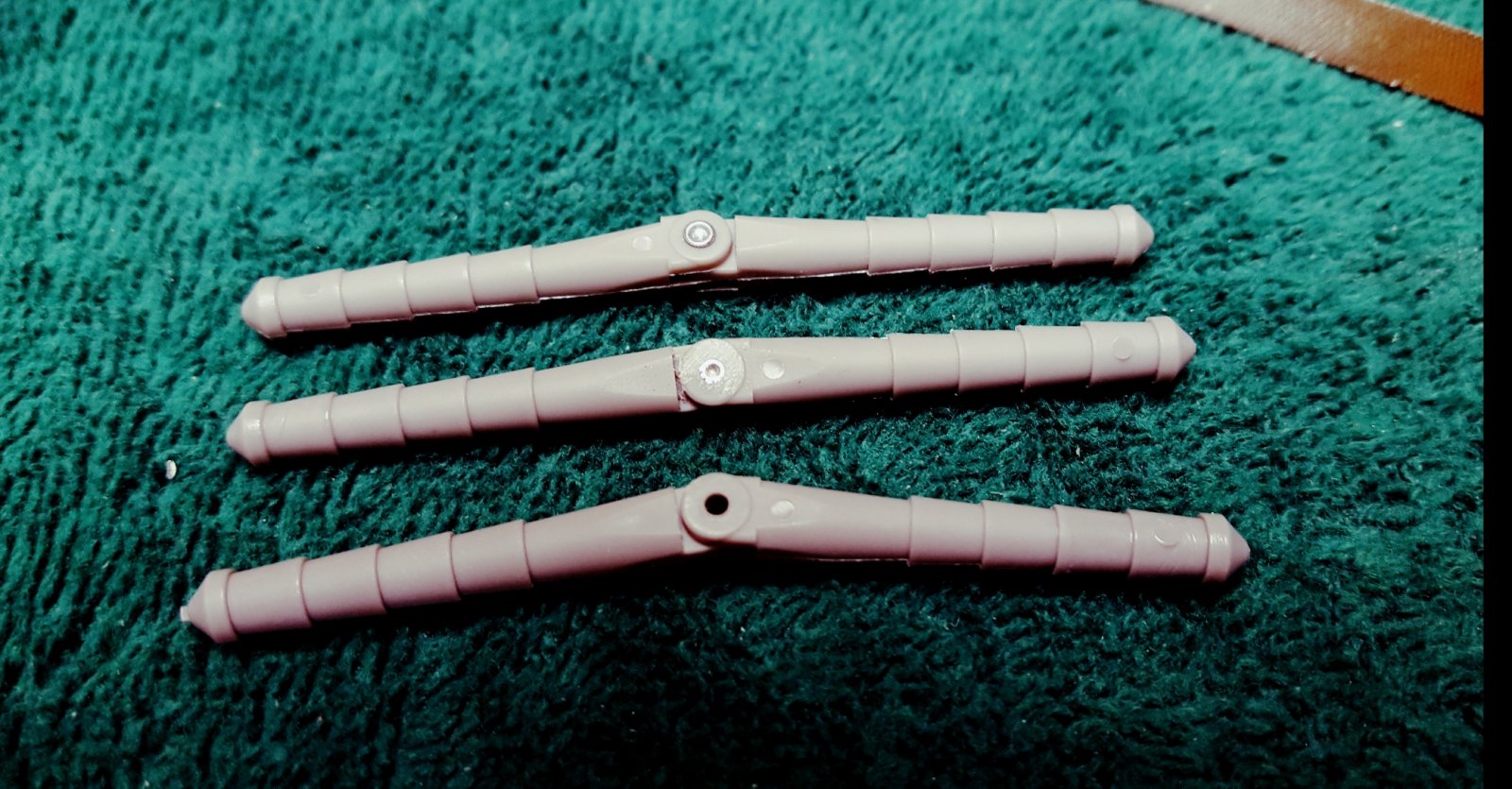

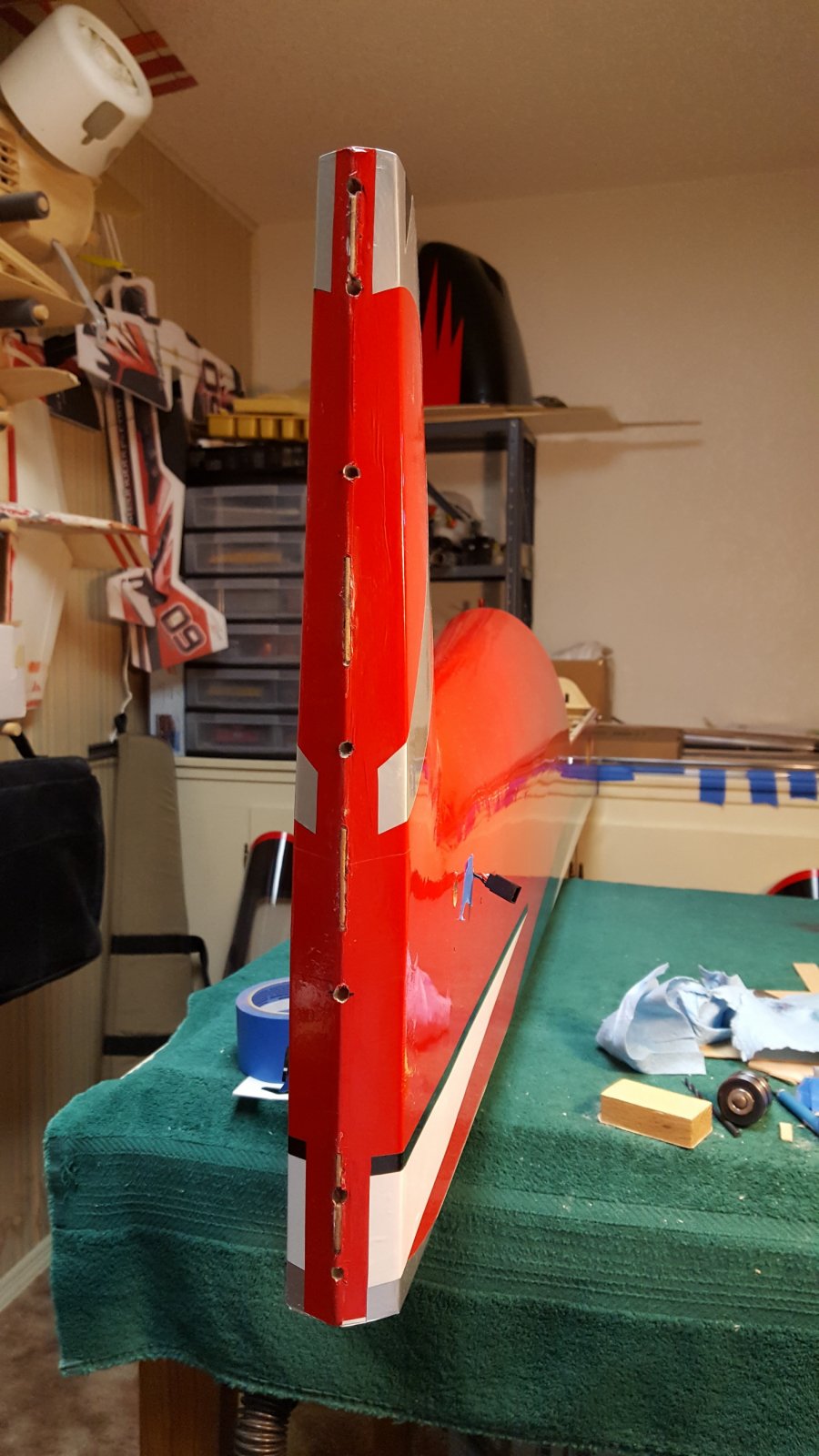

Tonight after spending a couple hours searching the Internet for stab tube for Miss Moana I worked on rehinging the rudder. I decided instead of buying Robart hinges without the pins I would remove the pins from some I had here. It didn't take very long at all to file the swedged end right off and push the pin out.

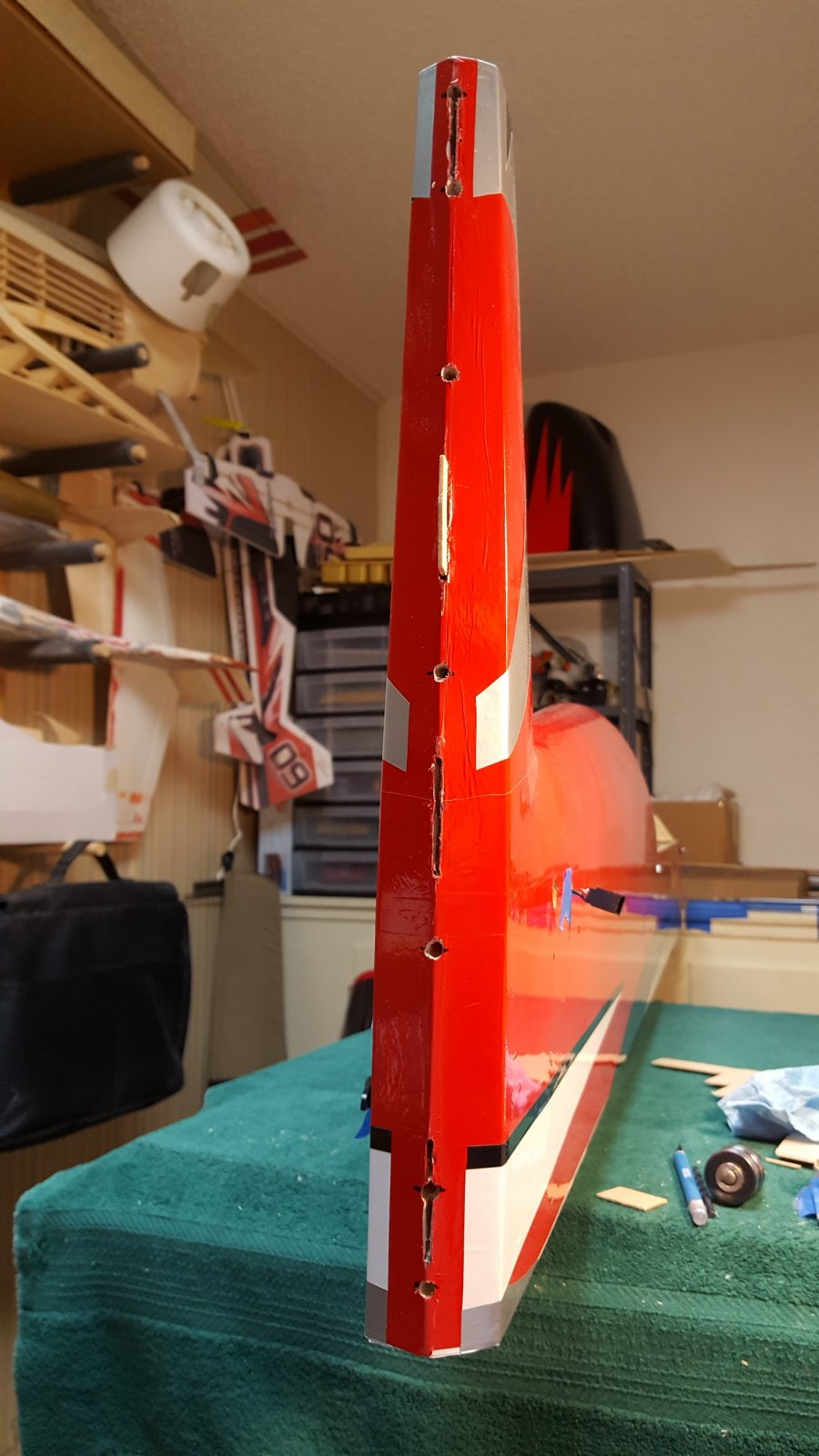

Boy, after removing the factory hinges I am really glad I did it. I had all the hinges out of the tail post in about 5 minutes. Two of them I just grabbed with a pliers gave them a wiggle and pulled them right out. The other ones needed just a blade run down the sides a little bit and they pulled right out. The new rudder was a bit harder to do, but not much.

Boy, after removing the factory hinges I am really glad I did it. I had all the hinges out of the tail post in about 5 minutes. Two of them I just grabbed with a pliers gave them a wiggle and pulled them right out. The other ones needed just a blade run down the sides a little bit and they pulled right out. The new rudder was a bit harder to do, but not much.

Jetpainter

640cc Uber Pimp

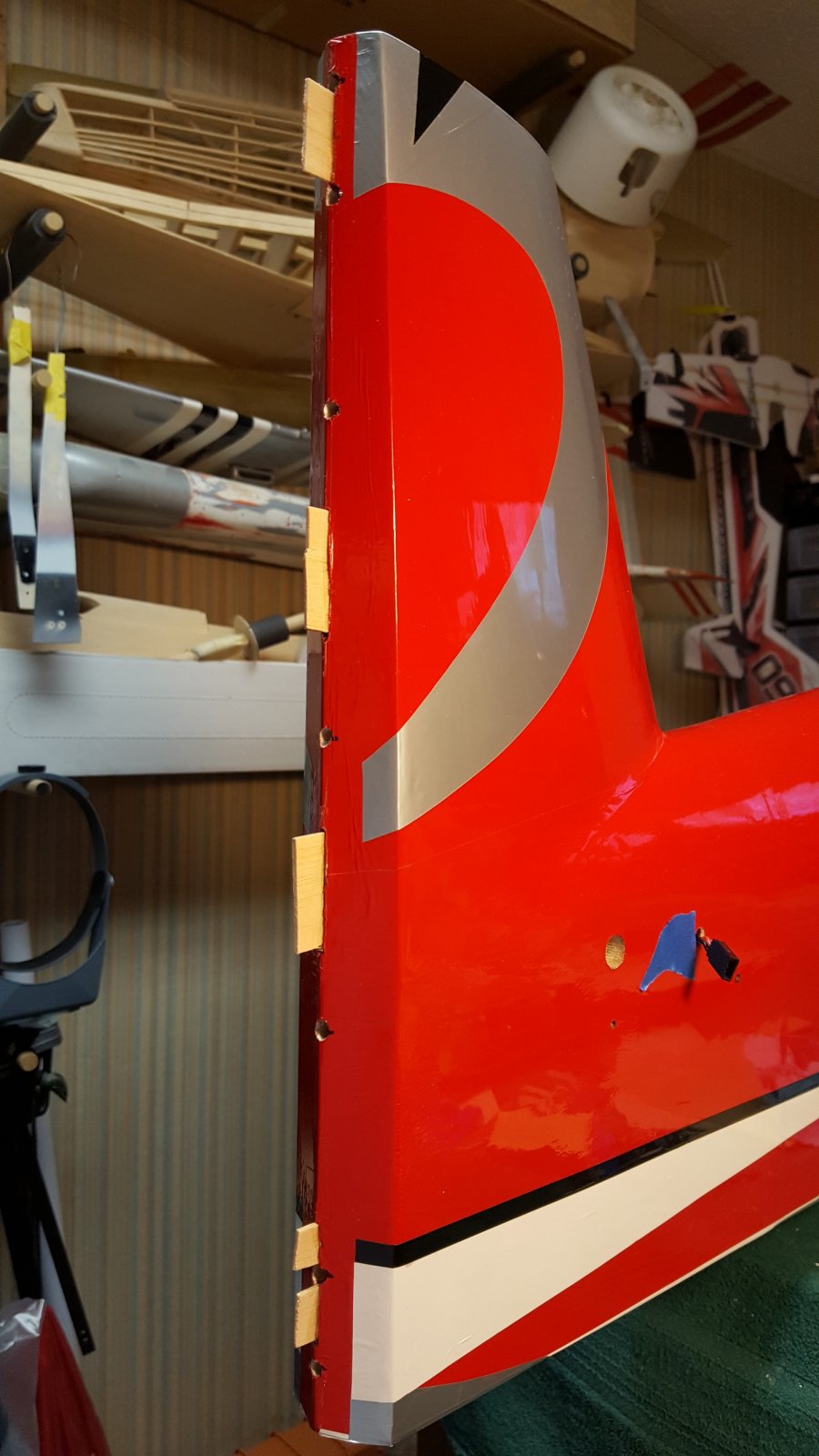

Last night I finished rehinging the rudder. I started by drilling new holes and fitting the hinges. Then I needed to fill in the slots from the original hinges with balsa wood. After trimming and sanding my balsa plugs I covered them with some red striping tape I had on hand. It's not a perfect match, but it sure isn't worth buying a roll of covering to change.

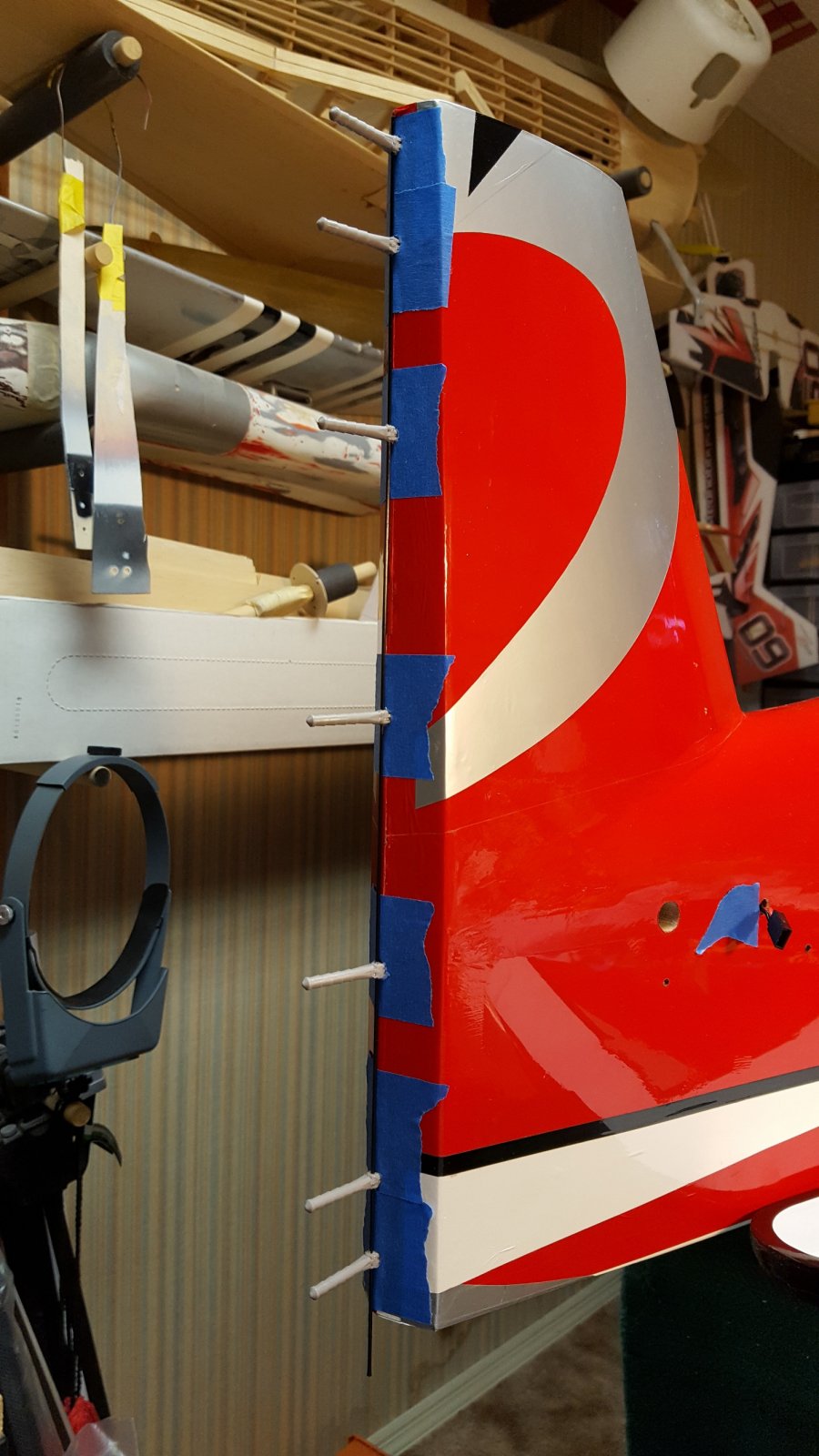

I then used @Terryscustom ideas for gluing in the hinges by using a hole punch and tape to protect the area around the hinge, and heating up some Vaseline in the bottom of an upside-down soda can and dipping the hinge section of the hinge in to keep glue from sticking to it. I also used Vaseline on my carbon fiber rod to keep glue from sticking to it.

After gluing the hinges in with 30 minute epoxy I waited until the epoxy had setup, but wasn't totally hard and picked off any excess glue and then pulled out the carbon fiber rod, took the rudder off, and cleaned of any epoxy or Vaseline.

I then used @Terryscustom ideas for gluing in the hinges by using a hole punch and tape to protect the area around the hinge, and heating up some Vaseline in the bottom of an upside-down soda can and dipping the hinge section of the hinge in to keep glue from sticking to it. I also used Vaseline on my carbon fiber rod to keep glue from sticking to it.

After gluing the hinges in with 30 minute epoxy I waited until the epoxy had setup, but wasn't totally hard and picked off any excess glue and then pulled out the carbon fiber rod, took the rudder off, and cleaned of any epoxy or Vaseline.