You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC Dalton 300 ml build thread.

- Thread starter orthobird

- Start date

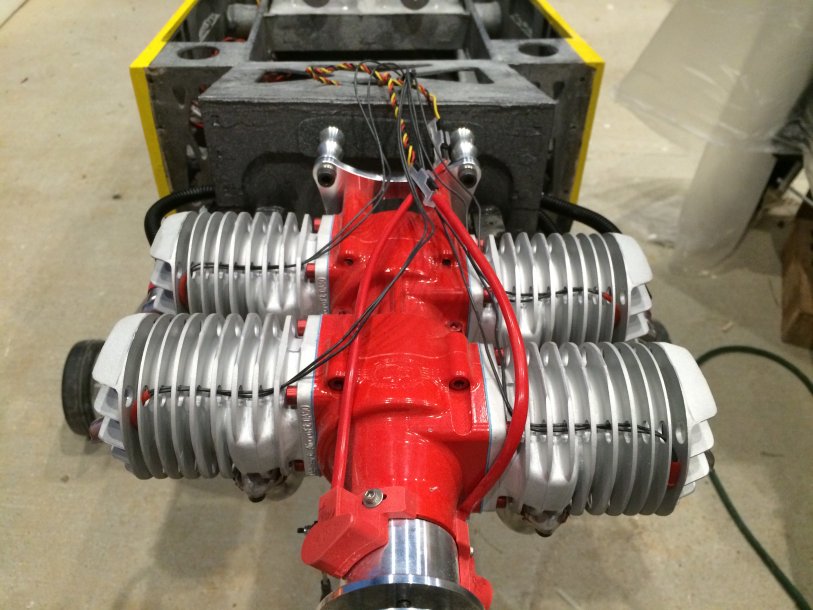

i have now installed the two CDI and the telemetry sensors for temps on all 4 cylinders!! this should be real cool. DO not know if it will work. i do not know if the Transmitter has capability to display 4 temps! But, if it does work, it will be wicked cool, as i will be able to know real time, the temps of the rear cylinders relative to the front cylinders!!! Should be interesting!

santiago3d92095

30cc

Very nice build, curious to see how close the temps are going to be in each cylinder

Very nice build, curious to see how close the temps are going to be in each cylinder

me too!!!

stangflyer

I like 'em "BIG"!

Hey Ortho.... been wondering about multiple temp sensors also. Been wondering if the telemetry packages will allow for (4) input signals. Keep us posted huh? Hey, by the way.... I've seen different placements for the temp probes... Curious if your readings will be accurate with them so close to the top of the combustion chamber. Just curious....

Hey Ortho.... been wondering about multiple temp sensors also. Been wondering if the telemetry packages will allow for (4) input signals. Keep us posted huh? Hey, by the way.... I've seen different placements for the temp probes... Curious if your readings will be accurate with them so close to the top of the combustion chamber. Just curious....

yes, it should work. each sensor module is made up of two temperature loops. so the front two cylinders are labelled A and B. (a for the right, be for left).

this will plug into channel 15.

the rear cylinders sensor will plug into channel 16.

i will have 4 temp readings, one for each cylinder.

the hottest area in a single or twin cylinder, will be the area in the prop was shadow, and the closest or highest up on the cylinder, to the spark plug. they even manufacture some sensors that are a ring that the spark plug sits on.

i want to know :"what is the hottest it gets!"

this temp is much different than temps from people who use IR guns.

so for example,

if airplane lands and you check temp using ir gun, it may read 170 F

but my telemetry will read 270 or so.

ok, i have a special interest over this, in a good way.

one one engine, i placed one sensor in the front and one in the back, same fin.

yep, 100 degree temp difference!!

ok, i put one sensor in bottom and top of cylinder.

also temp difference, the top and behind was the hottest.

ok, i put a sensor around the crankcase!! i am excited about this, as you can tell!!

yep, even cooler!

the temp on crankcase is about 130 to 170 F

normal temps if you measure from top of cylinder and in the shadow of prop wash will be between 190 F and 400 F.

once temp gets over 420 or so, then motor starts to do that "fade" thing.

you all know this, you accelerate and after a while, the rpm's start to drop, you bring rpm.s down, and then it behaves better.

until you go WOT, 20 seconds later, again rpm drops!!

when this happens, that means you do not have proper baffling and air exits!

remember 3 to 1 exit to entrance, and you need some form of air dams or louvres. the air dams will help create a negative pressure behind it that helps extract the hot air out.

Last edited:

wheel pants are getting primed. need to do a good sanding on them, then fill in pinholes, prime again, sand again, then prime last time before painting.

i have 4 options for painting this:

1. solid black (the bottom of the fuselage is black)

2. solid yellow

3. solid red

4. tricolor, horizontal stripes, from top to bottom : red, yellow, black

what would be best for me to see this and help me visualize this as a cue to bottom of airplane ? and wings level?

i have 4 options for painting this:

1. solid black (the bottom of the fuselage is black)

2. solid yellow

3. solid red

4. tricolor, horizontal stripes, from top to bottom : red, yellow, black

what would be best for me to see this and help me visualize this as a cue to bottom of airplane ? and wings level?