Jetpainter

640cc Uber Pimp

Rob is Baby going flying?

I considered it for tomorrow. But I would be going out alone. My son is feverishly burning the midnight oil and daytime sunlight rebuilding the front section of the fuse on his PAU Edge. Crazy how that structure would remind you of egg shells or non tempered glass. It never should have shattered the way it did. Anyway, I will probably stay home in the morning and work on the new Yak. I spoke to the "G" man on Friday. His parts order was delayed in customs until Thursday. So they were not able to get the 212 rebuilt. That was the plan for Friday. He mentioned Monday will probably be test run day and back into a shipping box to come home to its...new home. I want to get as much done on the new Yak as possible. Hopefully a maiden in a week or two.Rob is Baby going flying?

That was the plan, but I was trying to powerwash the back of my shop and do about 15 different things all at the same time, so did not get any pics. Hopefully I can get some pics of unwrapping and seeing if it fits in the fuse and how the wing tube fits etc.Photos k?

(When I sold my 104 some how the gas can I made had to go with it!?!?

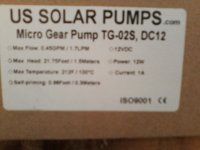

(When I sold my 104 some how the gas can I made had to go with it!?!? lol). Any who.....I found this cool little gear pump on Amazon for under 30 bucks and got to work making me a gallon sized fueler

lol). Any who.....I found this cool little gear pump on Amazon for under 30 bucks and got to work making me a gallon sized fueler

Nice Kelly, Would you post the link to where you got that pump? The pump I purchased for my gas can setup works. But when it comes to filling those Behemoth Fuel tanks, it takes a while. Heck, my unshaven stubble becomes a six inch beard before my tanks are filled. LOL.Found myself needing a new pump to fill the Extra with petrol 'O' plenty(When I sold my 104 some how the gas can I made had to go with it!?!?

lol). Any who.....I found this cool little gear pump on Amazon for under 30 bucks and got to work making me a gallon sized fueler

. The pump is 12 volts but I am running a 2S Lipo and getting 12oz a minute. Perfect for my 16oz tank in my Extra since I have downsized the cc's.......CUZ I CHEAP!

I also modified the Dubro can fitting with a nylon bushing insert to replace the O ring that kept coming out. Nice tight leak free fit now.

View attachment 97556 View attachment 97557 View attachment 97558 View attachment 97559 View attachment 97560 View attachment 97561 View attachment 97562

Nice Kelly, Would you post the link to where you got that pump? The pump I purchased for my gas can setup works. But when it comes to filling those Behemoth Fuel tanks, it takes a while. Heck, my unshaven stubble becomes a six inch beard before my tanks are filled. LOL.

View attachment 97563

Thanks bro.....

How did you know it was good for gasoline. Read the info but nothing.