wfahey415

3DRCF Moderator

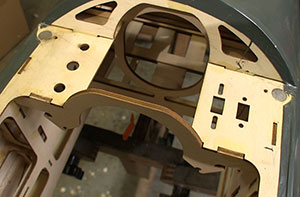

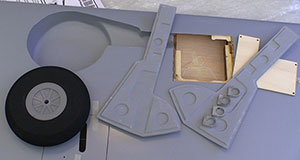

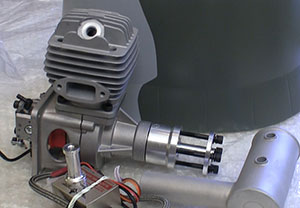

This is a special build by a very special person. Tom is a very close friend of mine and is battling Alzheimer's. One of his dreams is to build the Top Flight P-47 and fly it at Joe Nall this year. Unfortunately, he just didn't have the resources to pull it all together. So I formulated a game plan, I would purchase the plane, retracts, motor and electronics and have them all sent to Tom in North Carolina. He could do the build for his website and then fly the plane at Joe Nall. The folks at Nall got wind of the build and were nice enough to register Tom for the event as their guest. I will join Tom at Joe Nall in May and take possession of the aircraft there. The support for this build has been great. MilehighRC provided a great price on the EME 60 for this build. Rotoflow is providing a tank and Quickfire filter. Anderson RC was very helpful in acquiring all of the electronics for this build. And there is more great news to come with this build. Stay tuned.:thumbup:

Here is the first segment. opcorn:

opcorn:

http://www.flyingrc.net/tfp471.html

Here is the first segment.

http://www.flyingrc.net/tfp471.html