I am back!!

LOL

ok, this is a bit complicated,and I will try my best to explain what I have done. Reading other Carden build threads, I have come across some interesting reading from the great builders, whereby, they have predrilled the hinge line, prior to glueing on the LE and TE of the hinge line.

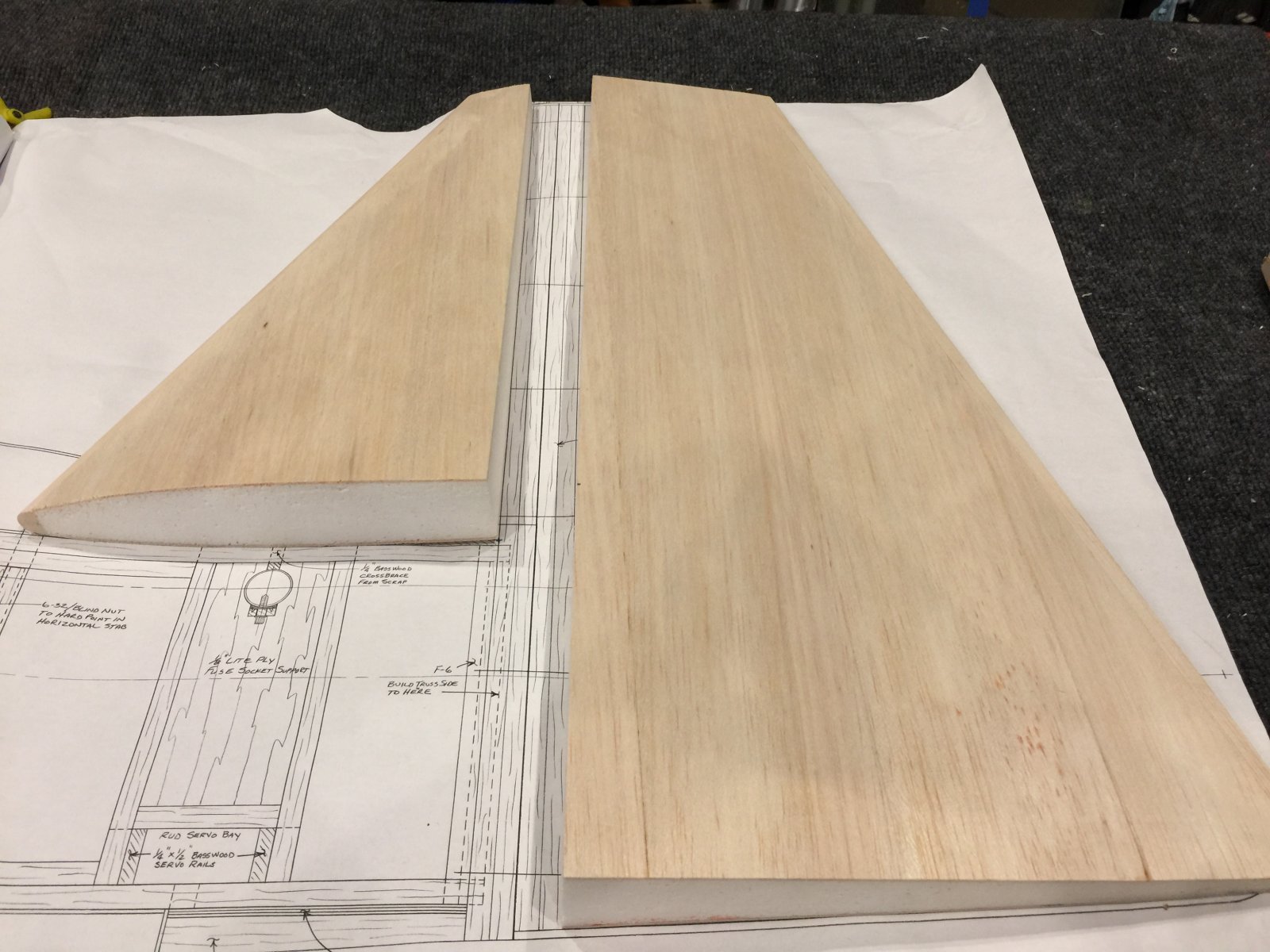

For the rudder, it requires that the LE and TE be 3/8" thick balsa. Then, I cut the rudder from the fin....

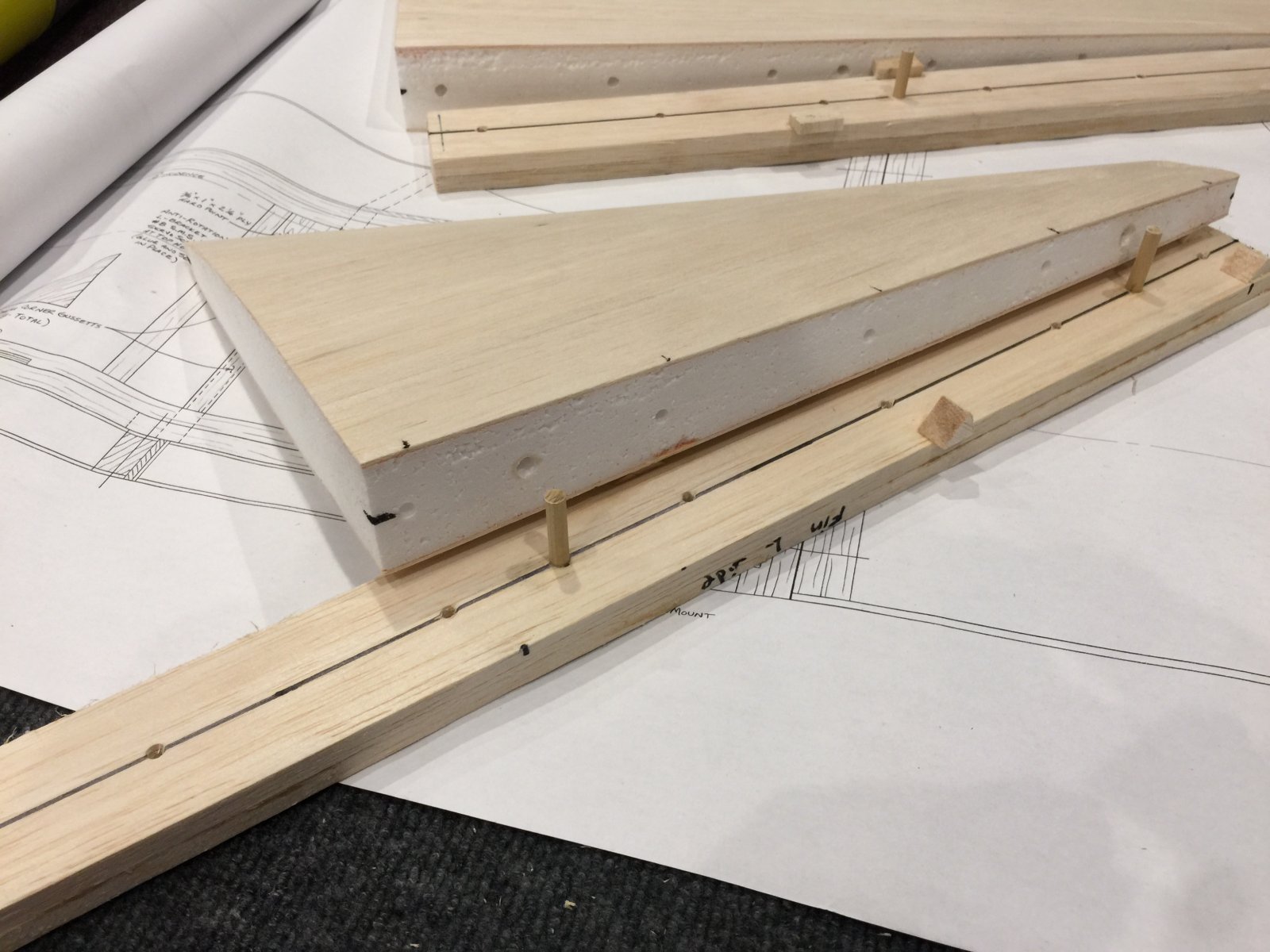

as you can see from the plans, it requires that the hinge line have two 3/8" thick balsa that are laminated together, to make 3/4" on the LE and 3/4" on the TE of the rudder hinge line.

Hope I am not confusing anyone with this. Therefore, the hinge line has a gap that is 3/4" + 3/4" = 1.5"

I have laminated two sets of 3/8" balsa that is 2.2" wide., for a distance of 3/4" ....

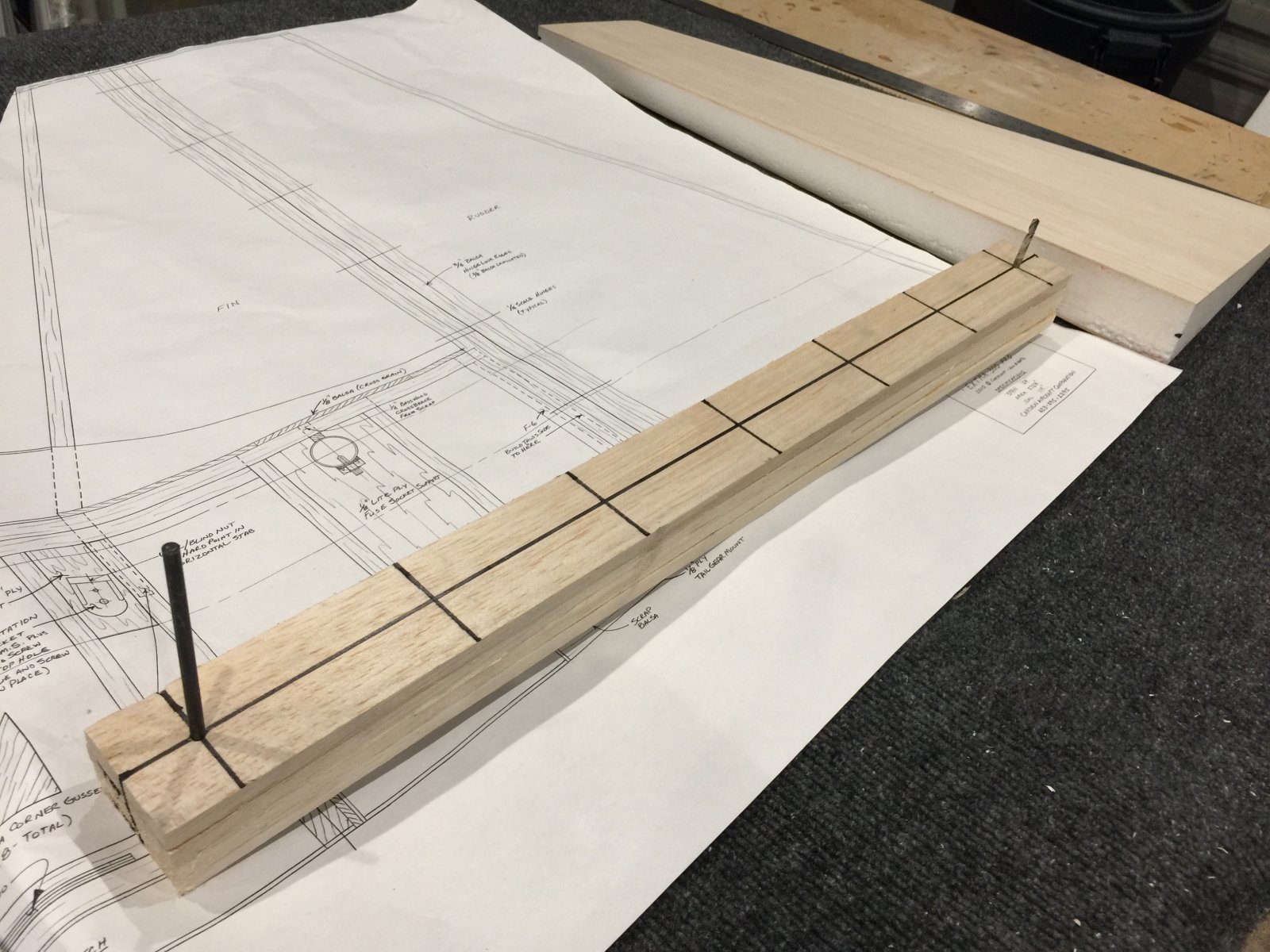

once each set of 3/8" + 3/8" (3/4" thick) laminate is dry, then I drew a center line on both the front and back side of each of the two. SO one of these will be the TE of the fin, the other one will be the LE of the rudder.

This should clarify it for you all....

Pretty self explanatory!

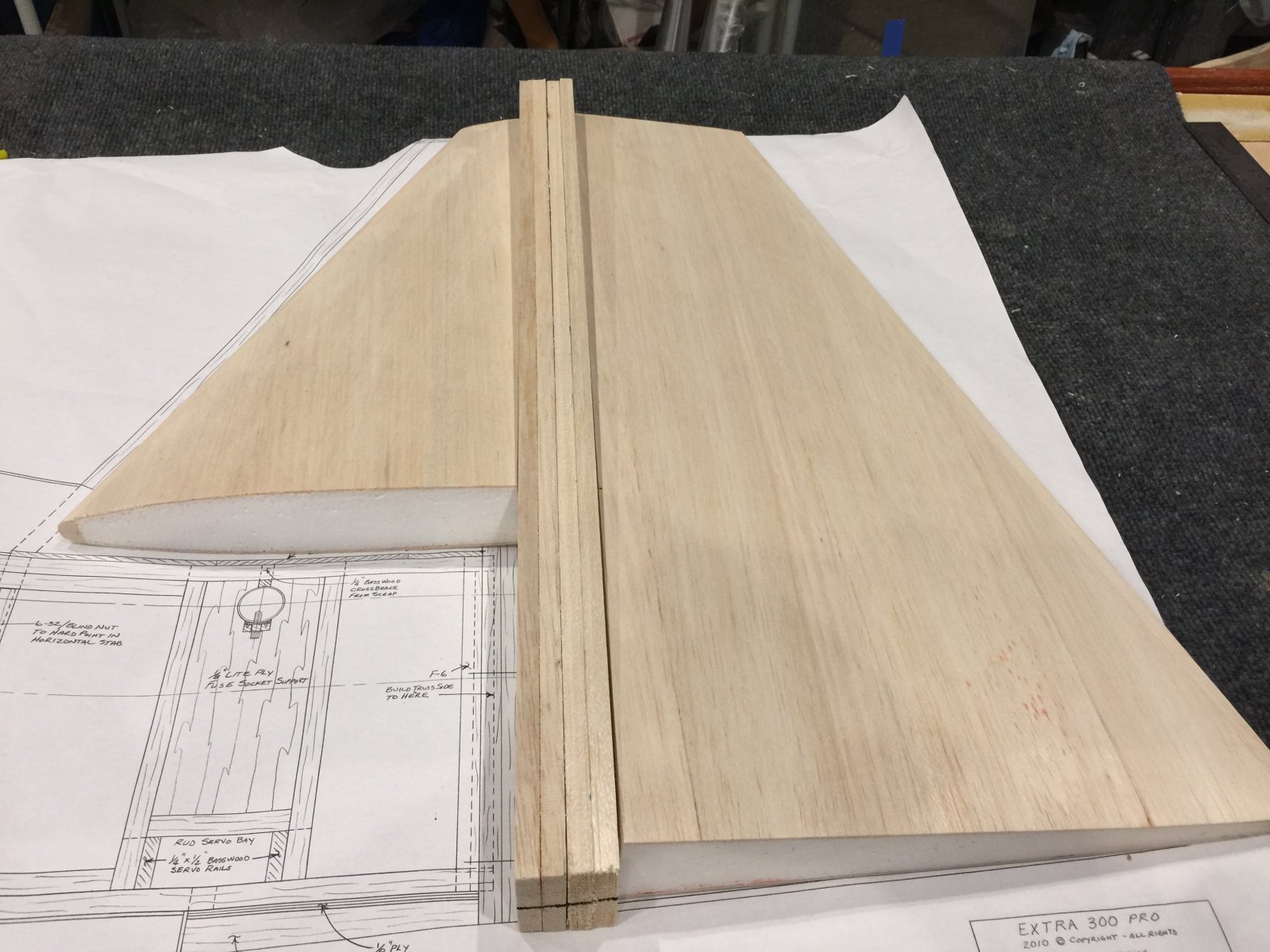

the bottom and top of them are aligned...

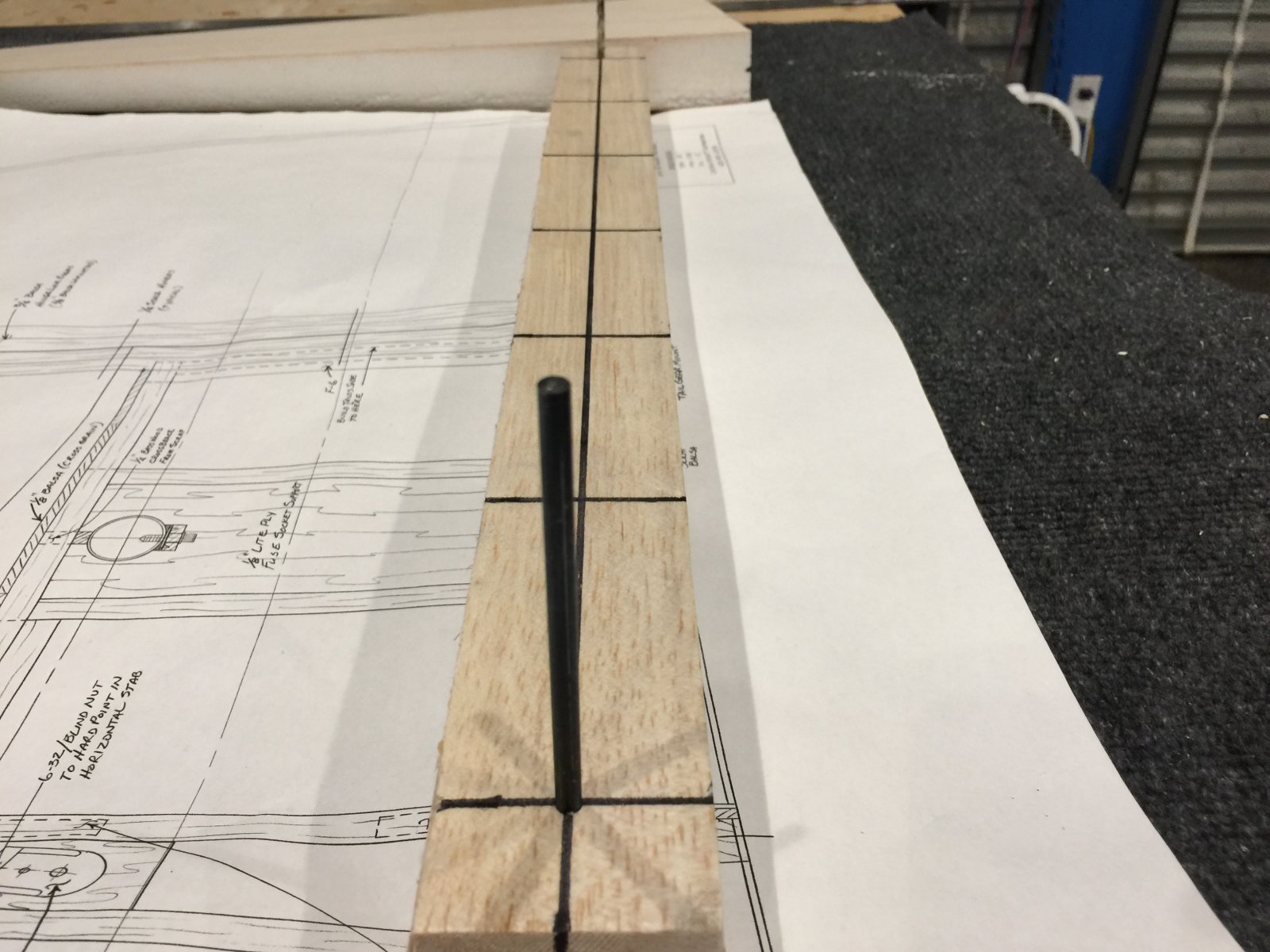

top view...

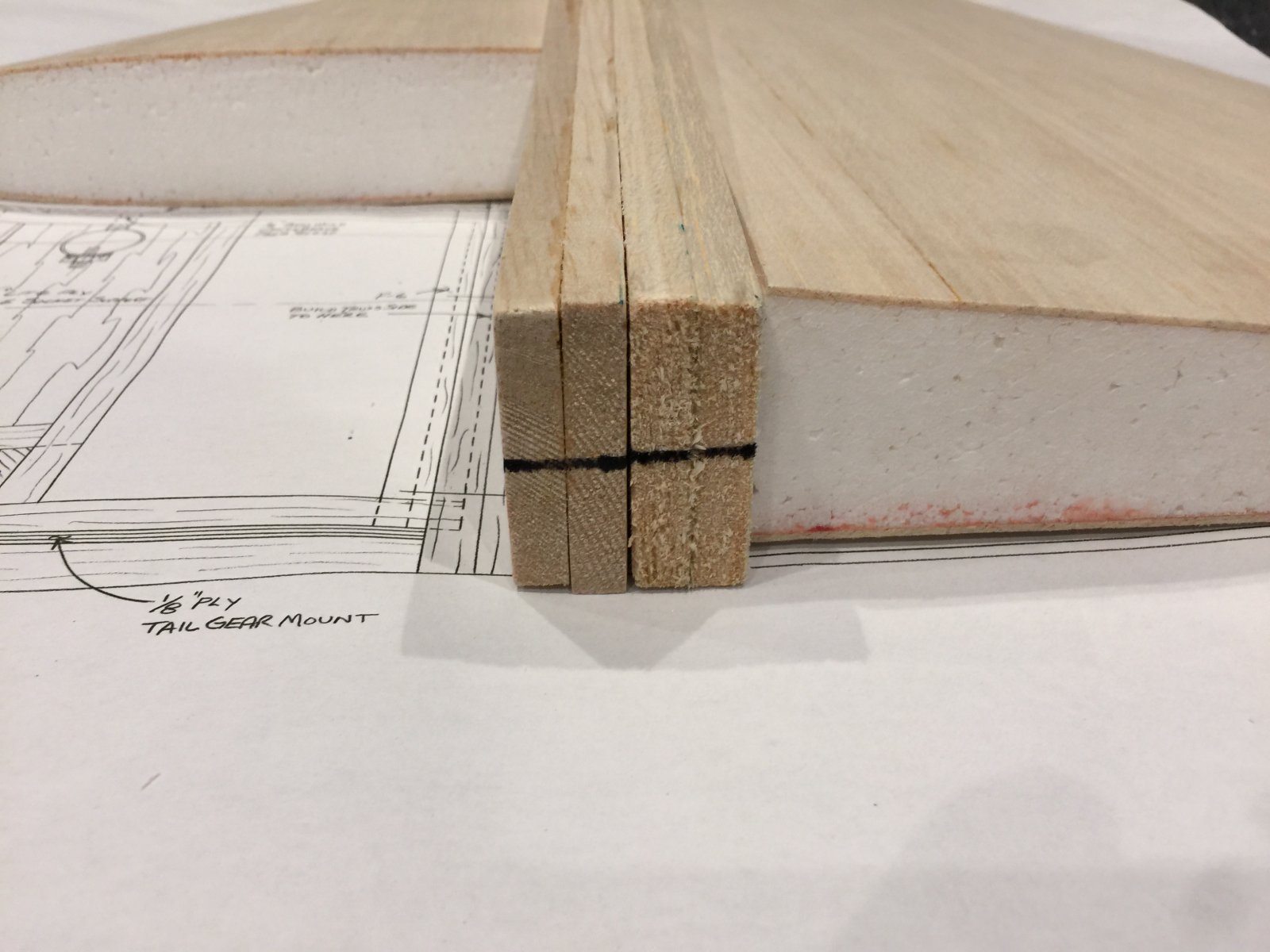

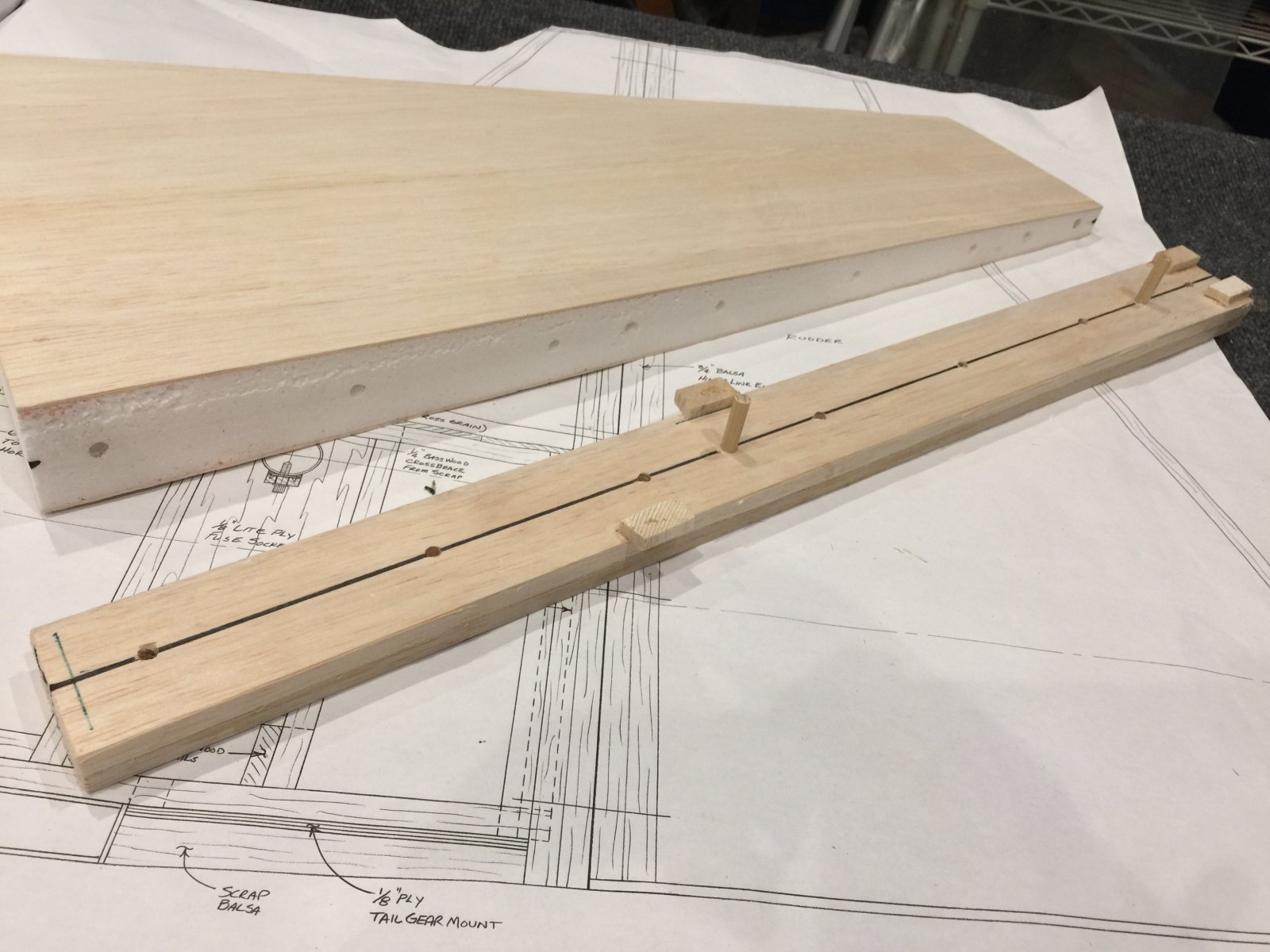

i then used the plans to see where the hinge points are recommended, looks like 7.

I then made sure that the both laminates were aligned, and drilled the top hole, pegged it, then drilled the bottom most hole, and pegged it, then I drilled the other 5 holes. Now, both laminates have the holes in line with each other!

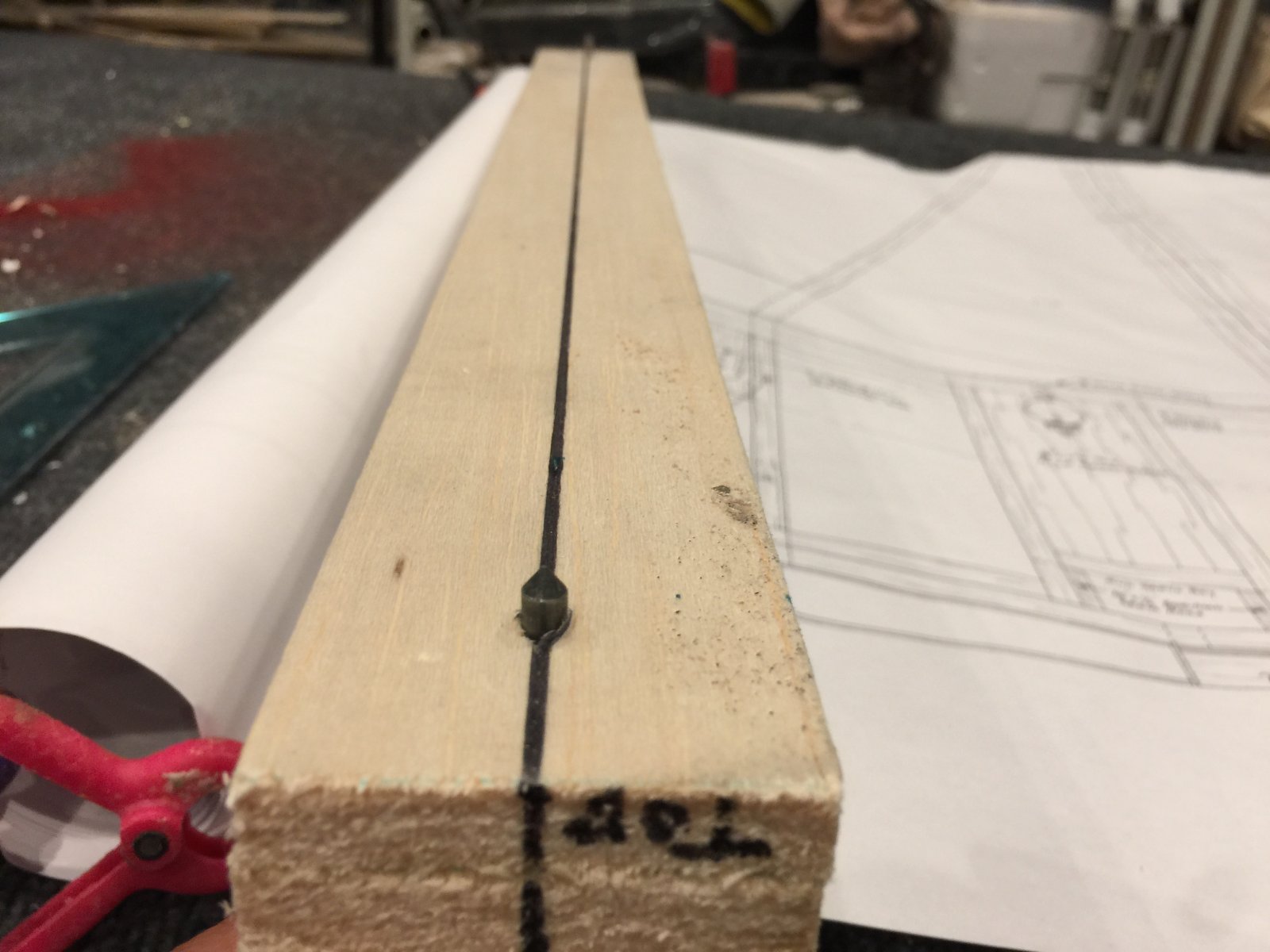

just to demonstrate how on the other side, my line was correct!

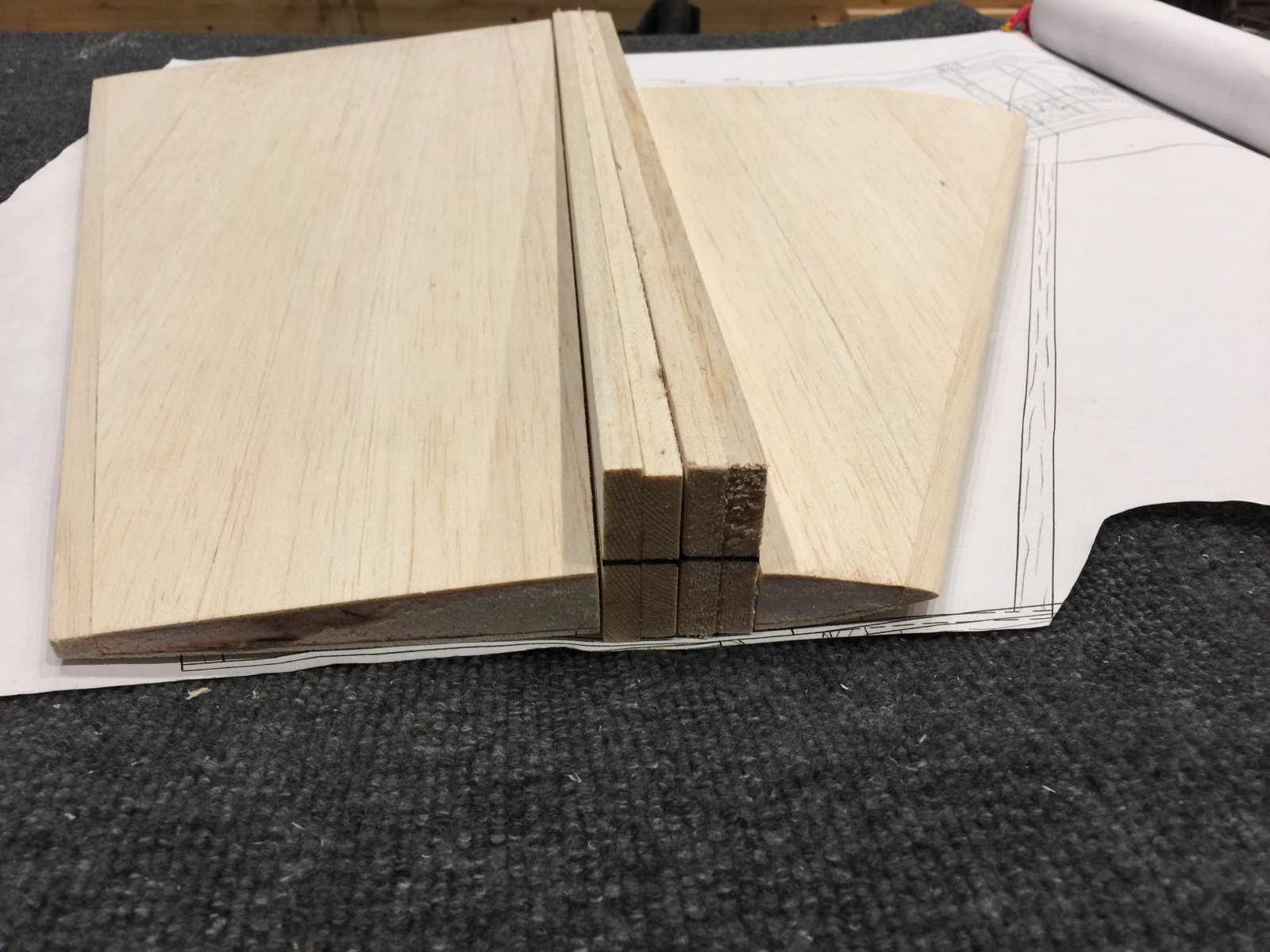

I then burned holes into the foam, and also drilled two more holes to fill with wood dowels, and once I glue them in, it will guide the laminate to the fin or rudder so that it remains inline...

Should be fun to see how it turns out...

LOL

ok, this is a bit complicated,and I will try my best to explain what I have done. Reading other Carden build threads, I have come across some interesting reading from the great builders, whereby, they have predrilled the hinge line, prior to glueing on the LE and TE of the hinge line.

For the rudder, it requires that the LE and TE be 3/8" thick balsa. Then, I cut the rudder from the fin....

as you can see from the plans, it requires that the hinge line have two 3/8" thick balsa that are laminated together, to make 3/4" on the LE and 3/4" on the TE of the rudder hinge line.

Hope I am not confusing anyone with this. Therefore, the hinge line has a gap that is 3/4" + 3/4" = 1.5"

I have laminated two sets of 3/8" balsa that is 2.2" wide., for a distance of 3/4" ....

once each set of 3/8" + 3/8" (3/4" thick) laminate is dry, then I drew a center line on both the front and back side of each of the two. SO one of these will be the TE of the fin, the other one will be the LE of the rudder.

This should clarify it for you all....

Pretty self explanatory!

the bottom and top of them are aligned...

top view...

i then used the plans to see where the hinge points are recommended, looks like 7.

I then made sure that the both laminates were aligned, and drilled the top hole, pegged it, then drilled the bottom most hole, and pegged it, then I drilled the other 5 holes. Now, both laminates have the holes in line with each other!

just to demonstrate how on the other side, my line was correct!

I then burned holes into the foam, and also drilled two more holes to fill with wood dowels, and once I glue them in, it will guide the laminate to the fin or rudder so that it remains inline...

Should be fun to see how it turns out...