You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC Double Build, Carden Pro 124" Extra 300 40%

- Thread starter orthobird

- Start date

-

- Tags

- 40% airplane build thread imac

I will do something different for the wings.

I want to use studs in the wing root, that enter the fuselage with the wings, and thus, they have to be parallel to the wing tube. This will make the preparation of the root caps for the wings different than the plans.

Additionally, I want to use 1/4-20 studs. May need to have some manufactured, But other wise, I will just use some threads. I will come on from opposite side, and drill into the foam 1st, then glue in the hard point with the root cap, then once I am ready to set the incidence, I can come in from opposite side again, and drill into the hard point. The glue in the root cap studs.

I have marked the location, on both fuselage sides, of the starter holes.

I want to use studs in the wing root, that enter the fuselage with the wings, and thus, they have to be parallel to the wing tube. This will make the preparation of the root caps for the wings different than the plans.

Additionally, I want to use 1/4-20 studs. May need to have some manufactured, But other wise, I will just use some threads. I will come on from opposite side, and drill into the foam 1st, then glue in the hard point with the root cap, then once I am ready to set the incidence, I can come in from opposite side again, and drill into the hard point. The glue in the root cap studs.

I have marked the location, on both fuselage sides, of the starter holes.

nevisian

New to GSN!

For the 1/4 20 studs,go to Lowes, look in the specialty nuts and bolt section, right across from the regular nuts and bolts, in those metal drawers, and you will find six in long steel studs.I will do something different for the wings.

I want to use studs in the wing root, that enter the fuselage with the wings, and thus, they have to be parallel to the wing tube. This will make the preparation of the root caps for the wings different than the plans.

Additionally, I want to use 1/4-20 studs. May need to have some manufactured, But other wise, I will just use some threads. I will come on from opposite side, and drill into the foam 1st, then glue in the hard point with the root cap, then once I am ready to set the incidence, I can come in from opposite side again, and drill into the hard point. The glue in the root cap studs.

I have marked the location, on both fuselage sides, of the starter holes.

View attachment 54079

Last edited:

nevisian

New to GSN!

I see your point. I have been using the Jtec incidence ajusters,so that's not an issue.for me.For the 1/4 20 studs,go to Lowes, look in the specialty nuts and bolt section, right across from the regular nuts and bolts, in those metal drawers, and you will find six in long steel studs.

Jetpainter

640cc Uber Pimp

Cam, I think those gussets are a laminate of carbon fiber and balsa - n0t just painted black balsa.

Correct. Laminated. @IMAC FANATIC can confirm as he was present during Dave Dixon's build.

I agree with Dirt, looks like cf lamination. I got CF arrow shafts at the local bow hunter supply store, he had a bucket full of broken ones for free.

I just realized what I had done. I had written a sentence with improper English. Forgive me, my 1st language is not English, but I have learned it in 1975, they taught it in my home country. In any event, I want to clarify what I was asking, or wanting to ask.

In that sentence, I mentioned:

Dave Dixon used these gussets, his are painted black, is that necessary......

well, here is my goof up!

I was not asking if the gusset being black or laminated was necessary, I was wanting to ask, do I have to use all those gussets?

Being that, it is not in the plans. I did receive a message from Dean @Fixed Wing, and he explained, it is not necessary, but, would not hurt.

As I had mentioned before, I will make the incidence and placement of wing bolts way easier. Well, at least, much easier for me, and in my comfort zone.

I will elaborate.

The plans and manual have it such that, on the root cap, a plywood is installed with blind nuts, and the wing is fastened to the fuselage using an 8-32 screw with a washer.

I do not like this method, not that it is bad or not worthy, but only, out of my preference. I would prefer to do it differently and in my comfort zones. The way I will do it, to me, is way easier.

OK, here it is:

I will 1st glue on the hard points in the fuselage, based on what is mentioned in the plans, and once cured, I will drill a hole from the outside in, and in an angle, which is probably 4.5 degrees off perpendicular to the fuselage side, based on Dean's measurements, which he mentioned in his thread. Then, I will assure that a drill bit can come in from opposite side to the side in question. This has to be square, and so far, I have accomplished it on both fuselages.

This is the hard point, already glued in. I am using a small drill bit, 1/8" diameter.

I then drilled all the way across to other side, and entered the hard wood thru the small 1/16th pilot hole I predrilled. now this side the hole is "square".

Here is the long drill bit out the other side. I then removed this, and came in again from this side into the opposite side, just to make both holes "in line".

Like this.

this is that long bit, and again, this is now done to all 4 holes on both Fuse #1 and #2.

the next step: I will place the wings on (which are totally untouched, nothing has been done yet), and then I will set the incidence to ZERO, and heat up the tip of the this small bit. Then I will enter the foam of the wing root by 1", and do the same for all the wings.

After this "pilot" hole is placed in the root of the wings, then I will obtain a wood dowel, that is about 1" diameter, and cut it to a 1.25" length. Then I will trace the outline of the dowel over the small hole, so that the center of the dowel will be in line with the pilot hole. Then I will core this foam out, for a 1.25" deep, and then glue in the dowel into the wing root. Then I will glue on the root cap, with the fuselage on its side. DO one by one, to make sure the root cap is flush with the fuselage side. Then I will sheet the wings so that the balsa sheeting go over the root cap. Somewhere in there, I have left out installation of the wing tube phenolic and the reinforcement of the foam with an upper and lower spar.

Ok, once the wings are sheeted and LE and TE is sanded and beveled, then I will place the wings on the fuselage, one side at a time, set my incidence to ZERO, and then, using this small drill bit, come in from opposite side, and drill into the hard point. once I am certain it is zero again, then I will leave the drill bit in the forward hole, and recheck again, then get another drill bit, and come in to the aft wing bolt hard point, drill it with the 1/8" bit 1st, recheck incidence, and then drill it with a 15/64 bit, that is long, and then install the 1/4-20 stud. then replace the wing, and do the front hard point.

Regarding the stud, i have several options, and I will list my #1 preference 1st:

1. Obtain the aluminum threaded stud, that DA used to sell. I emailed Dave, and he states, they have not manufactured them in a while, due to their machines (CNC, i imagine), being in such high production for other things. If they ever get caught up, they will whip up a batch of them bad boys, but for now, they do not have them. I have contacted Vern, at white rose, and he explained to me, that he could make them, however, it requires programming of his CNC machine, and understandably so, it would be labor intensive, and even though he has not told me, seems to me, that It would not be worth his effort to manufacture 8 or 12 of these for me. I do not blame him. For now, this seems like something I will not be getting.

2. Option 2, go to Lowes and obtain the 1/4 - 20 thread / studs, and then, glue in the nylon bushing that Tony, from Dalton aviation sells. these bushing will go into the holes made. SO now, the threads, as the wings are put in and out, will not "wallow" out the hole over time.

3. Use those studs, and glue on a aluminum or brass tube over it, that is 3/8" in length.,

#3 might be best way to go for now.

I will keep you all updated as to what happens.

I will elaborate.

The plans and manual have it such that, on the root cap, a plywood is installed with blind nuts, and the wing is fastened to the fuselage using an 8-32 screw with a washer.

I do not like this method, not that it is bad or not worthy, but only, out of my preference. I would prefer to do it differently and in my comfort zones. The way I will do it, to me, is way easier.

OK, here it is:

I will 1st glue on the hard points in the fuselage, based on what is mentioned in the plans, and once cured, I will drill a hole from the outside in, and in an angle, which is probably 4.5 degrees off perpendicular to the fuselage side, based on Dean's measurements, which he mentioned in his thread. Then, I will assure that a drill bit can come in from opposite side to the side in question. This has to be square, and so far, I have accomplished it on both fuselages.

This is the hard point, already glued in. I am using a small drill bit, 1/8" diameter.

I then drilled all the way across to other side, and entered the hard wood thru the small 1/16th pilot hole I predrilled. now this side the hole is "square".

Here is the long drill bit out the other side. I then removed this, and came in again from this side into the opposite side, just to make both holes "in line".

Like this.

this is that long bit, and again, this is now done to all 4 holes on both Fuse #1 and #2.

the next step: I will place the wings on (which are totally untouched, nothing has been done yet), and then I will set the incidence to ZERO, and heat up the tip of the this small bit. Then I will enter the foam of the wing root by 1", and do the same for all the wings.

After this "pilot" hole is placed in the root of the wings, then I will obtain a wood dowel, that is about 1" diameter, and cut it to a 1.25" length. Then I will trace the outline of the dowel over the small hole, so that the center of the dowel will be in line with the pilot hole. Then I will core this foam out, for a 1.25" deep, and then glue in the dowel into the wing root. Then I will glue on the root cap, with the fuselage on its side. DO one by one, to make sure the root cap is flush with the fuselage side. Then I will sheet the wings so that the balsa sheeting go over the root cap. Somewhere in there, I have left out installation of the wing tube phenolic and the reinforcement of the foam with an upper and lower spar.

Ok, once the wings are sheeted and LE and TE is sanded and beveled, then I will place the wings on the fuselage, one side at a time, set my incidence to ZERO, and then, using this small drill bit, come in from opposite side, and drill into the hard point. once I am certain it is zero again, then I will leave the drill bit in the forward hole, and recheck again, then get another drill bit, and come in to the aft wing bolt hard point, drill it with the 1/8" bit 1st, recheck incidence, and then drill it with a 15/64 bit, that is long, and then install the 1/4-20 stud. then replace the wing, and do the front hard point.

Regarding the stud, i have several options, and I will list my #1 preference 1st:

1. Obtain the aluminum threaded stud, that DA used to sell. I emailed Dave, and he states, they have not manufactured them in a while, due to their machines (CNC, i imagine), being in such high production for other things. If they ever get caught up, they will whip up a batch of them bad boys, but for now, they do not have them. I have contacted Vern, at white rose, and he explained to me, that he could make them, however, it requires programming of his CNC machine, and understandably so, it would be labor intensive, and even though he has not told me, seems to me, that It would not be worth his effort to manufacture 8 or 12 of these for me. I do not blame him. For now, this seems like something I will not be getting.

2. Option 2, go to Lowes and obtain the 1/4 - 20 thread / studs, and then, glue in the nylon bushing that Tony, from Dalton aviation sells. these bushing will go into the holes made. SO now, the threads, as the wings are put in and out, will not "wallow" out the hole over time.

3. Use those studs, and glue on a aluminum or brass tube over it, that is 3/8" in length.,

#3 might be best way to go for now.

I will keep you all updated as to what happens.

Last edited:

Some more fun. Before I do anything, I have labelled the airframe for the quad as #1, and now, I will do some tests.

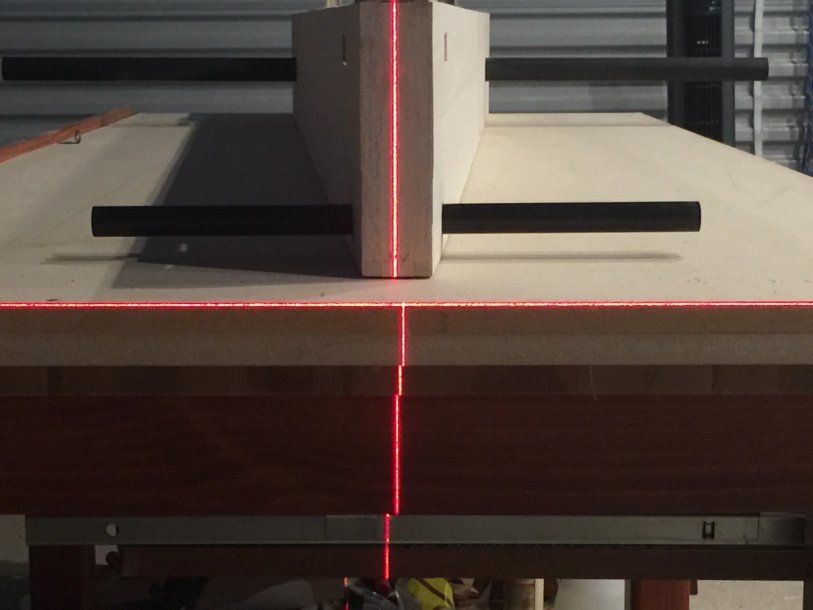

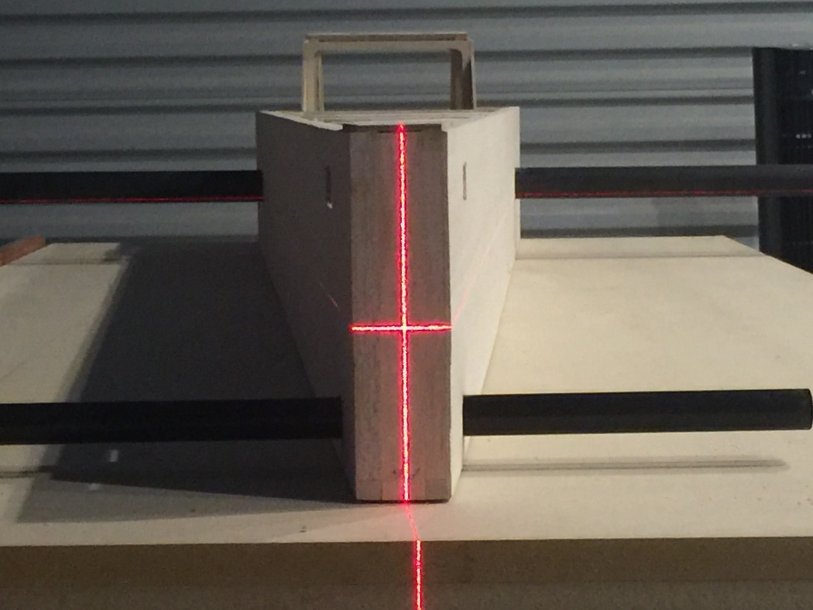

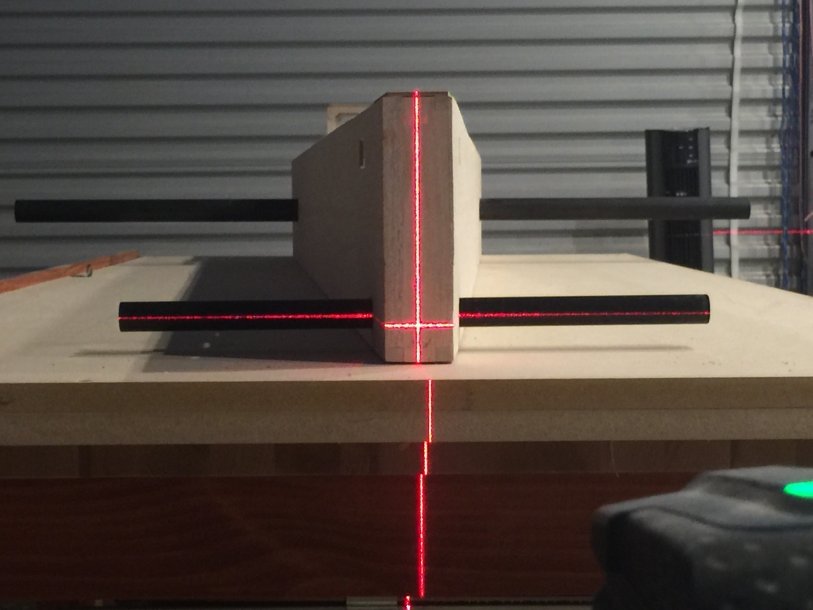

i first want to make sure my table top is level. I used a level and the laser light.

once this was confirmed, I will then check that everything else is referenced from the table top. I also did this on the other side of the table, and, using the level, I checked the middle of the table, so all is level now.

Then, I looked at the stab tube and the wing tube, and I am very satisfied so far.

I am heading to our club now, as there is a spring fly in, have to be there. but when I get back, I will check the distance from the right stab tube tip to the wing tube tip and compare to opposite side.

Then I will do all these tests for the other fuselage.

i first want to make sure my table top is level. I used a level and the laser light.

once this was confirmed, I will then check that everything else is referenced from the table top. I also did this on the other side of the table, and, using the level, I checked the middle of the table, so all is level now.

Then, I looked at the stab tube and the wing tube, and I am very satisfied so far.

I am heading to our club now, as there is a spring fly in, have to be there. but when I get back, I will check the distance from the right stab tube tip to the wing tube tip and compare to opposite side.

Then I will do all these tests for the other fuselage.