You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC Dalton Yak 54, 38% please submit suggestions here....

- Thread starter orthobird

- Start date

Naughty Monkey

100cc

Haven't seen anything in this the thread to make me think it won't.

I have some good info for you:

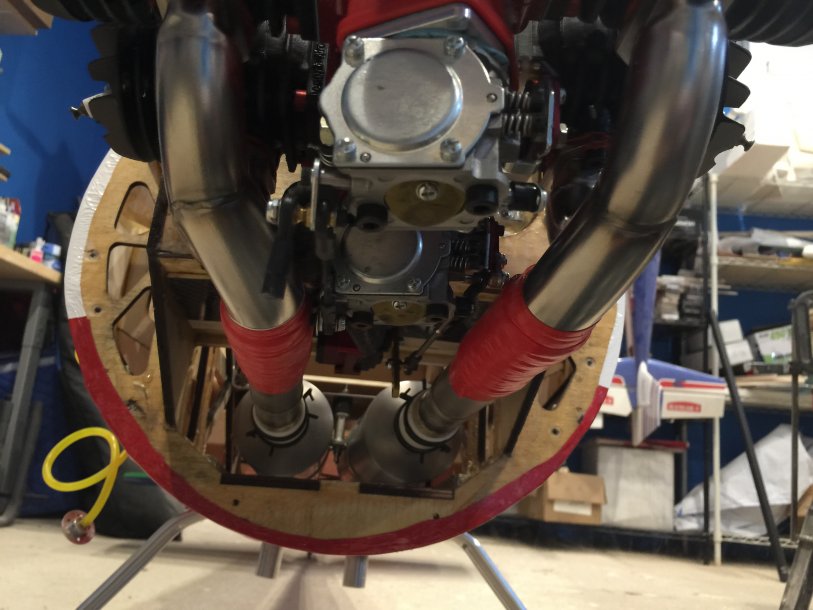

I have placed 6 temp sensors:

4 are on the bottom side of the tops of the cylinders, where the shadow of the air flow would be:

temp range is from 180 to 250 F, front and real cylinders have same temps. I am using that shroud I built. Ambient temp is 95 F.

Ok, one temp sensor (#5) is on the header, this reads 120 degrees F

the last sensor (#6) is in between the headers, near to the servo and the carbs, the temps are in 100 to 104 F range.

What do you think about the air flow in my cowl with those temps?

I have placed 6 temp sensors:

4 are on the bottom side of the tops of the cylinders, where the shadow of the air flow would be:

temp range is from 180 to 250 F, front and real cylinders have same temps. I am using that shroud I built. Ambient temp is 95 F.

Ok, one temp sensor (#5) is on the header, this reads 120 degrees F

the last sensor (#6) is in between the headers, near to the servo and the carbs, the temps are in 100 to 104 F range.

What do you think about the air flow in my cowl with those temps?

just did some research, and the temp range for servos is up to 140 F.

Based on my sensor, the air near to the servo area has a temp that is 105 F.

I do not know if that will add to the internal servo temp created, what the actual servo temp would be?

I am just not happy those headers come so close to everything!!!

Based on my sensor, the air near to the servo area has a temp that is 105 F.

I do not know if that will add to the internal servo temp created, what the actual servo temp would be?

I am just not happy those headers come so close to everything!!!

Steps to finish:

1. Mark the holes/measure, for hinge pins.

2. bevel the LE of the aileron and TE of the wings

3. cap the roots and tips

4. finish filling/sanding the surfaces/wings

5. cover with monokote

6. glue the hinges in

7. seal the hinge gap

8. glue in the control horns

9. install the servos

10 match the servos

11. make the instrument panels

12. need a pilot

then i will be finished!

1. Mark the holes/measure, for hinge pins.

2. bevel the LE of the aileron and TE of the wings

3. cap the roots and tips

4. finish filling/sanding the surfaces/wings

5. cover with monokote

6. glue the hinges in

7. seal the hinge gap

8. glue in the control horns

9. install the servos

10 match the servos

11. make the instrument panels

12. need a pilot

then i will be finished!