You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC Dalton Yak 54, 38% please submit suggestions here....

- Thread starter orthobird

- Start date

Jetpainter

640cc Uber Pimp

90 degree head for a Dremel tool would work, or an angle drill. Harbor Freight has several cheap ones that would probably work.

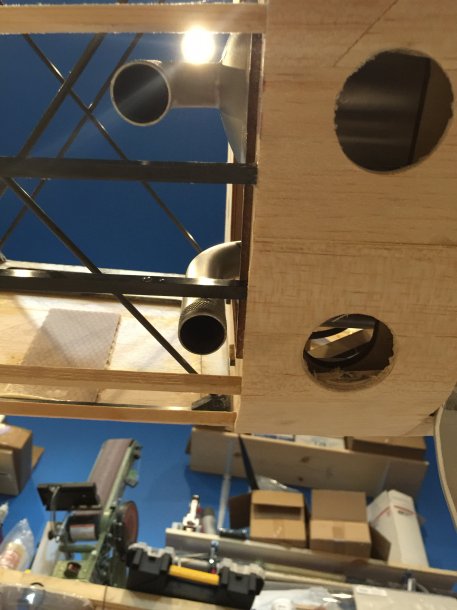

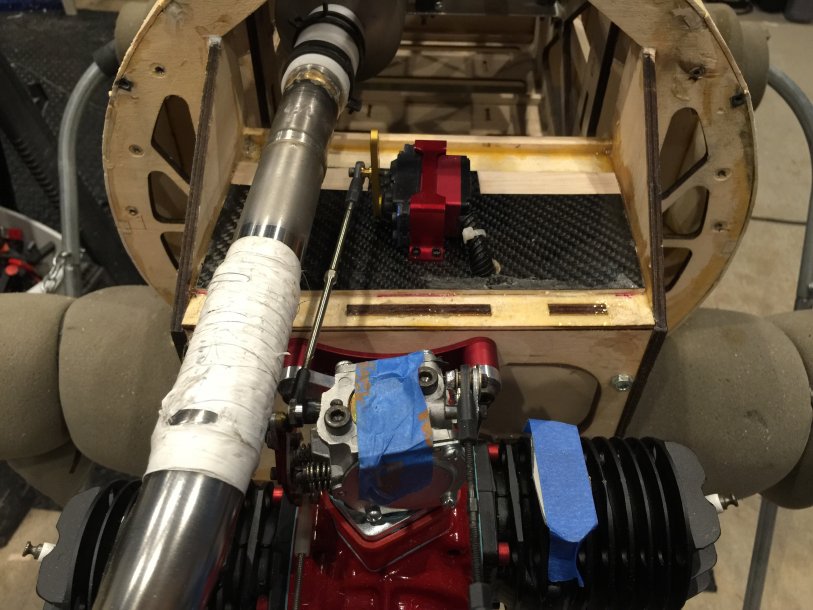

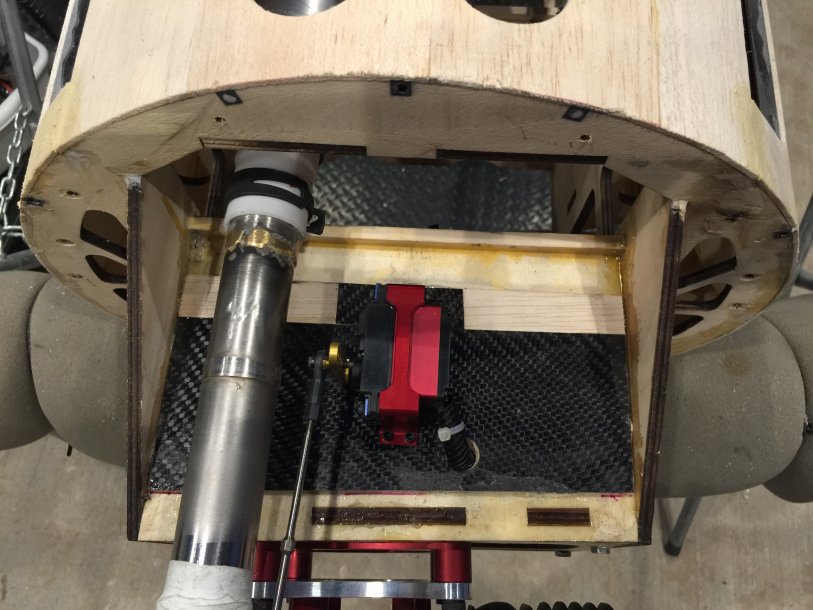

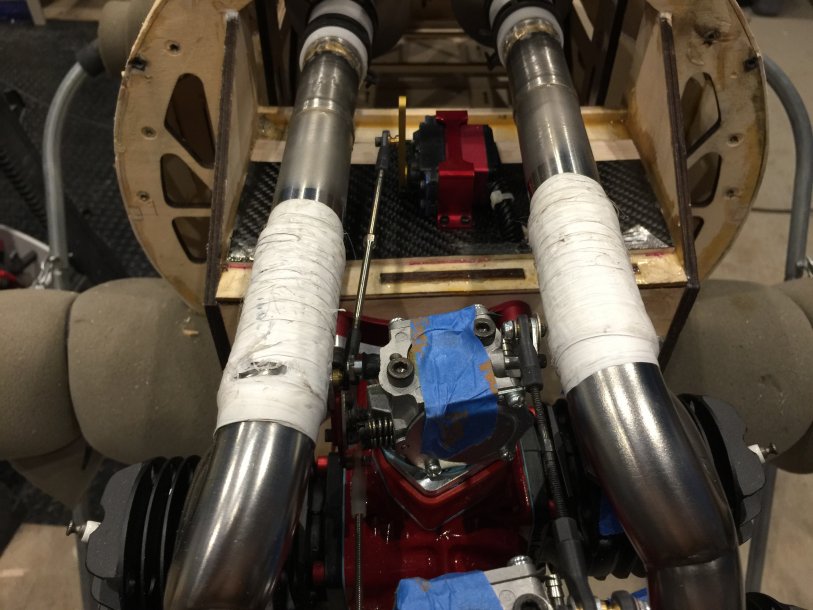

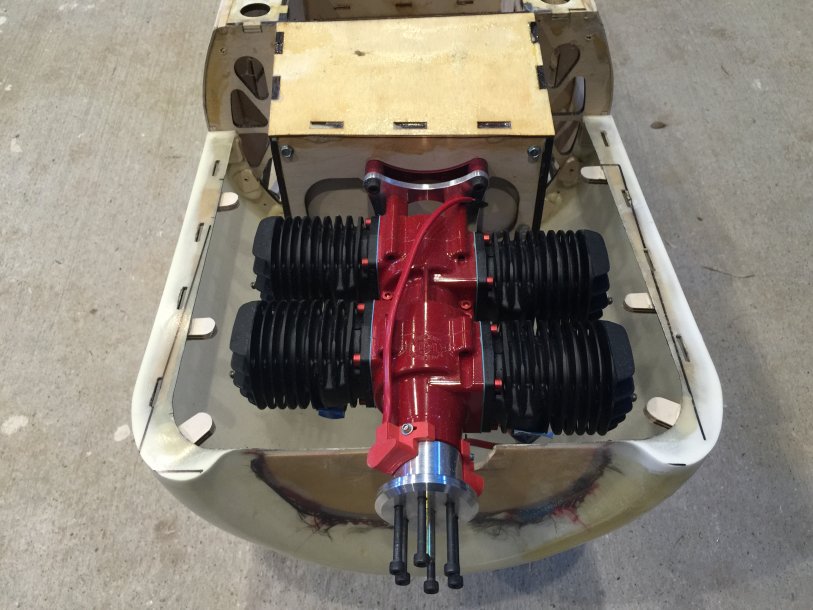

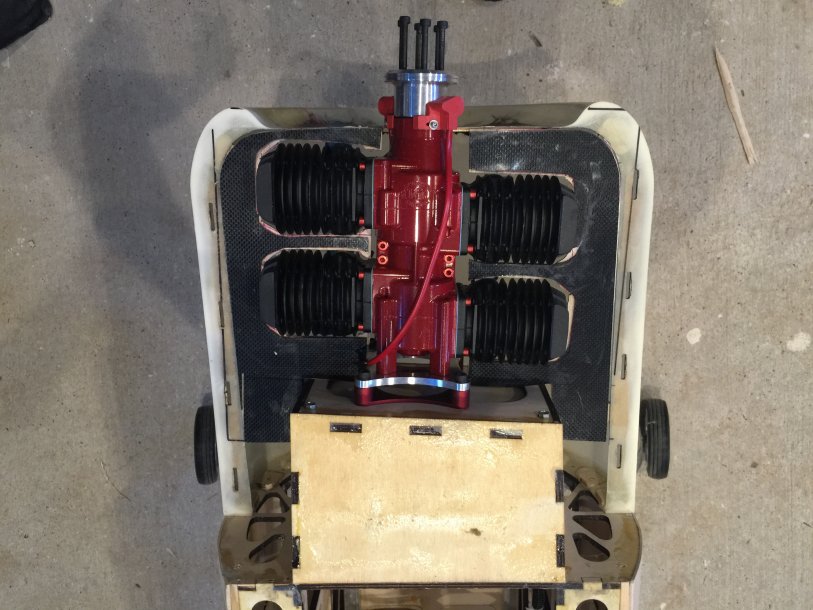

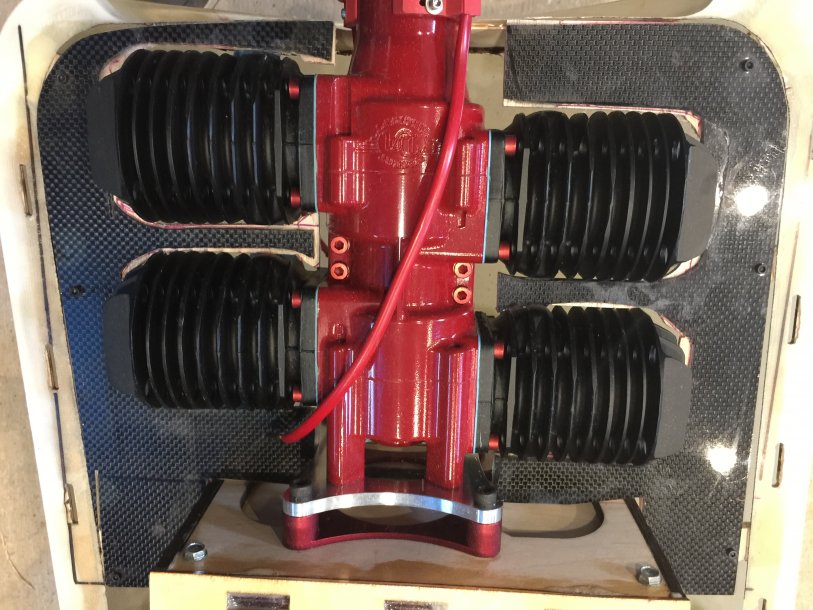

OK, I need a beer now, or two!! I got it in there and they are solid. I am very pleased with the results, but it was not easy!! let me see if the pics will show you what I have done..

SOon, i will have to undo all this!!! LOL!!!

The good thing is, that the aluminum plate is held in place with 4 screws, 2 on each side, with blind nuts on opposite side. Access to it is quite easy, so I am not worried.

SO that I can sheet the bottom and cut out holes for the stingers, and do the rest of the stuff that needs to be done, like covering the airplane. All that is left is to do is mount the throttle servo, and we will be done.

Then finish beveling the wings/ailerons, and cover wings/stabs, etc....

SOon, i will have to undo all this!!! LOL!!!

The good thing is, that the aluminum plate is held in place with 4 screws, 2 on each side, with blind nuts on opposite side. Access to it is quite easy, so I am not worried.

SO that I can sheet the bottom and cut out holes for the stingers, and do the rest of the stuff that needs to be done, like covering the airplane. All that is left is to do is mount the throttle servo, and we will be done.

Then finish beveling the wings/ailerons, and cover wings/stabs, etc....

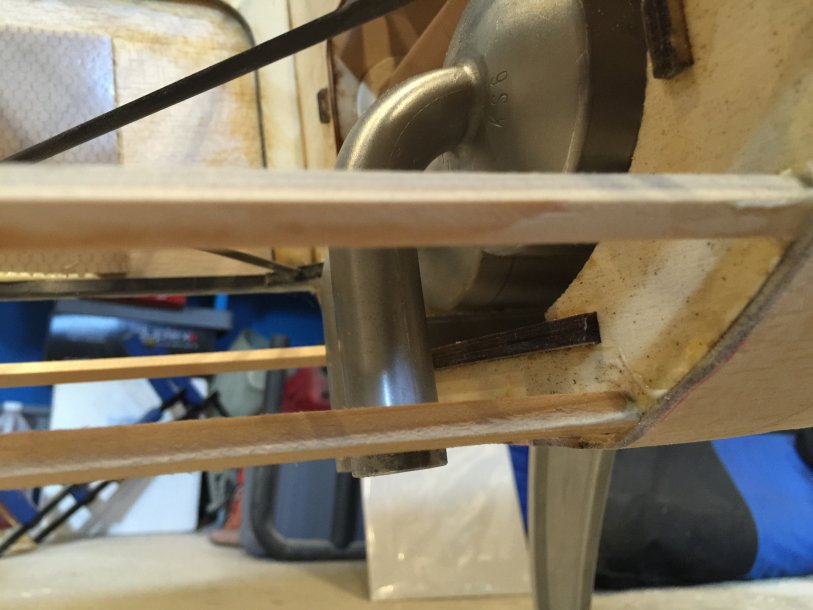

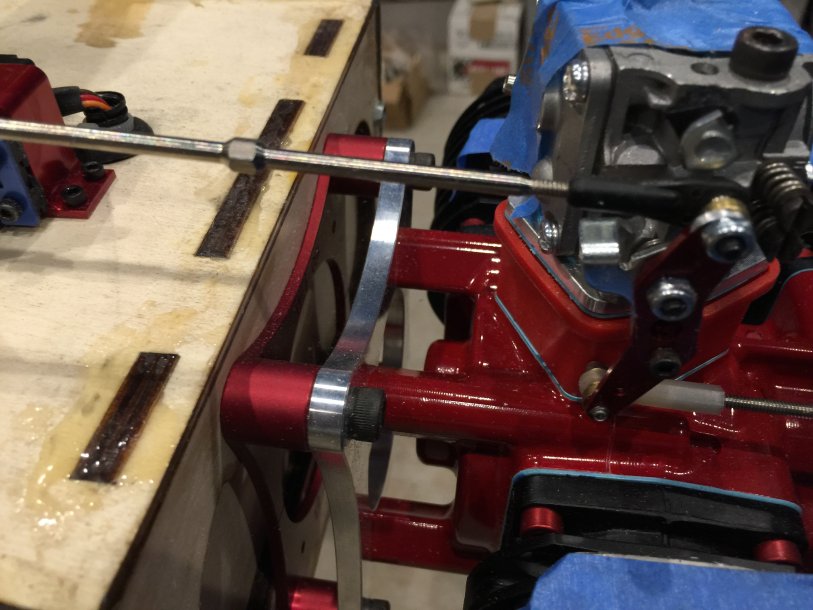

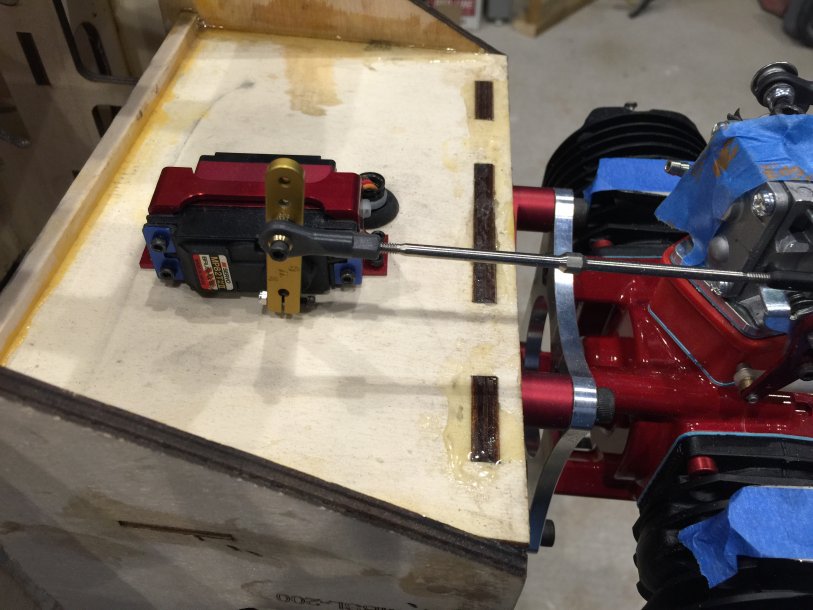

Installed the throttle servo: This is a tight install, very little room, seems like the way the headers are designed with this drop, I will not be able to get to the needles for the rear carb ;( ... Nothing is binding or impinging, but very close where the throttle arm is in proximity to the header. If only the headers were out by 1 cm.

Dirt Doctor

50cc

Looks great Cam, remember a millimeter is as good as a kilometer!!

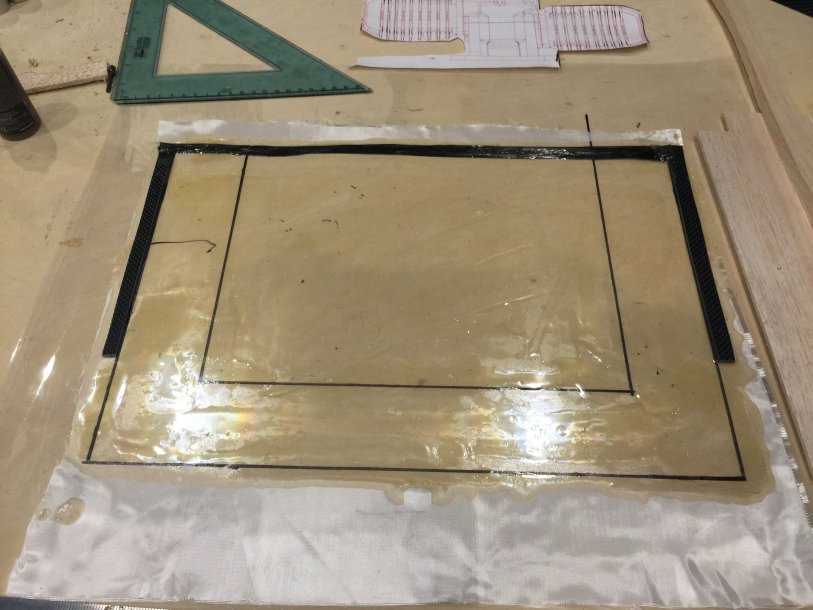

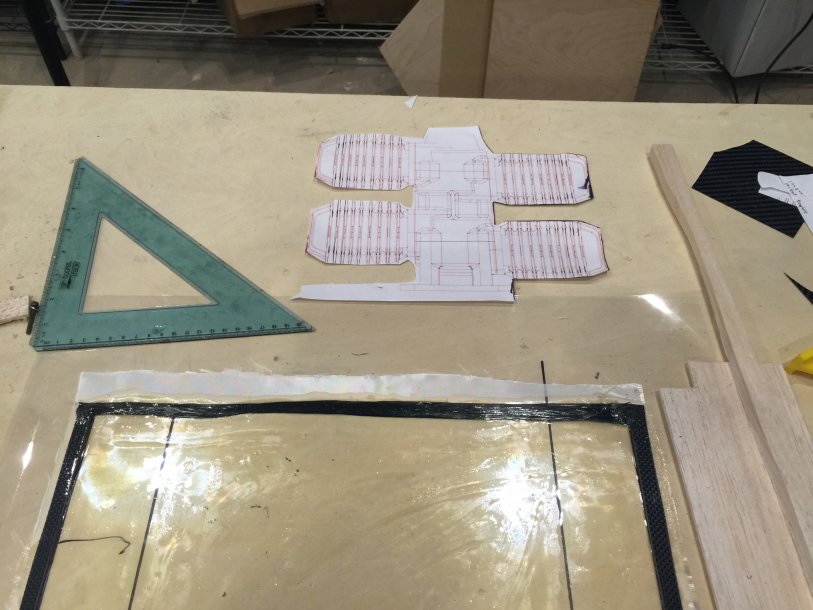

I have glued on the baffle plate mounting tabs.

Then I placed the baffle plate on and positioned it...

Then i drilled into the tab, and inserted a 4-40 screw.

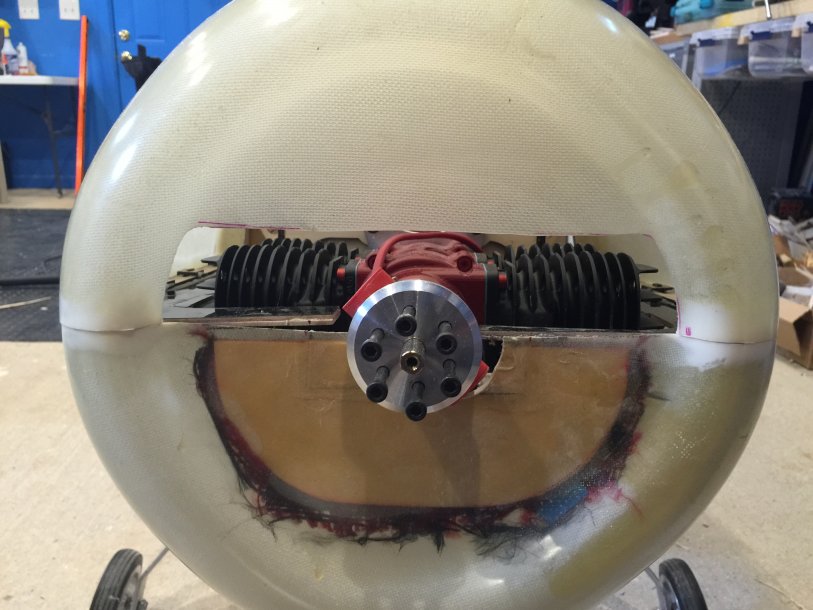

Here is a frontal view. The opening has a 2" height. Next step is to make the shroud.

these are two views of the propeller clearance...

Then I placed the baffle plate on and positioned it...

Then i drilled into the tab, and inserted a 4-40 screw.

Here is a frontal view. The opening has a 2" height. Next step is to make the shroud.

these are two views of the propeller clearance...

I am going to manufacture my own plenum (or shroud), whatever you want to call it. Basically, it will be something that will contain the prop wash into a smaller area above the cylinders, that way, the air has only one way to go, and that is down and out thru the cylinder fins.