You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC Dalton 300 ml build thread.

- Thread starter orthobird

- Start date

I got some interesting information to share with you all.

My Dalton now has 115 flights, over 20 hours up in the air.

This is regarding the beauty of Telemetry. I know there are nay-sayers out there, but I want to demonstrate an example where it is very very handy.

On my transmitter, I have placed an AMP usage per flight on my front screen. Meaning, the moment i turn my ignition on, the transmitter will inform me on how many MaH are being used until i turn off the ignition, meaning from time motor is on til I turn it off.

The usage will be displayed as such that Battery 1 = 300 mah and Battery 2 will be = 300 Mah.

This is just an example. Those are not real numbers.

Ok, what has happened, about 50 flights ago, I changed the throws on the ailerons, meaning, increased the throws mechanically. And i have also changed the mixes (do not know if this changed anything).

But, I can recall, at first, a 12 minute flight, whereby I practiced the Sportsman sequence 3 times, was consuming about 200 to 250 Mah per battery.

In the past 2 weeks, i recall now seeing that it was 600 mAh per battery, meaning 1200 Mah, per 12 minutes, or 100 Mah per minute of flight.

The airplane has JR MP 82T HV servos, and 2 sets of IBEC, the number of servos is 9.

I got some advice this weekend, and this is what I did:

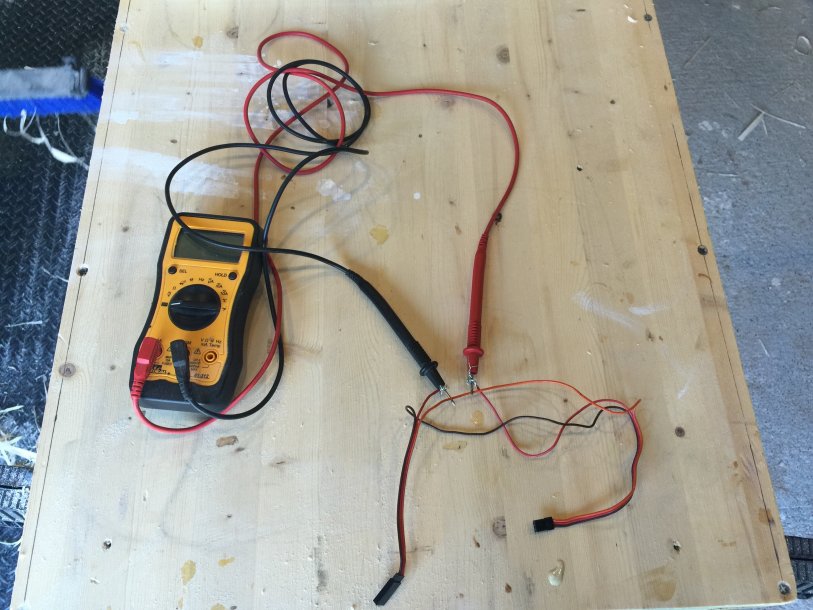

I obtained a voltmeter, and made a lead, whereby I tapped the red lead of the servo extension, and this went thru the amp meter.

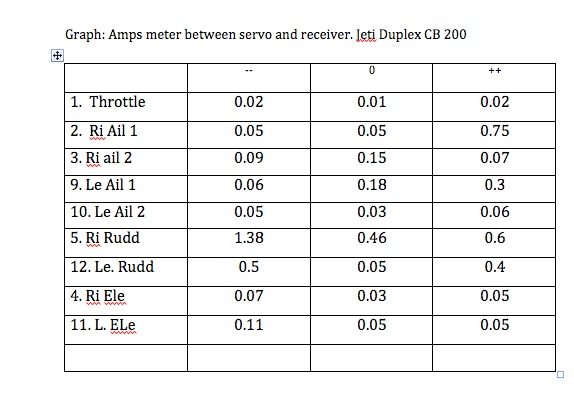

I then proceeded to measure each individual servo, and this graph demonstrates the results:

One thing i want to say is, that these servos are very quiet, they do not buzz, unless they are binding significantly.

but clearly it is evident that my ailerons servos and rudder servos were binding.

The measurements of one wing were made, one servo first, then adjustments made, then the other servo was measured, therefore, I do not know how much more the other servo was off, since the "bind" was addressed prior to making that reading.

Overall, the telemetry helped me, in that, I was able to discover there was a binding issue.

My Dalton now has 115 flights, over 20 hours up in the air.

This is regarding the beauty of Telemetry. I know there are nay-sayers out there, but I want to demonstrate an example where it is very very handy.

On my transmitter, I have placed an AMP usage per flight on my front screen. Meaning, the moment i turn my ignition on, the transmitter will inform me on how many MaH are being used until i turn off the ignition, meaning from time motor is on til I turn it off.

The usage will be displayed as such that Battery 1 = 300 mah and Battery 2 will be = 300 Mah.

This is just an example. Those are not real numbers.

Ok, what has happened, about 50 flights ago, I changed the throws on the ailerons, meaning, increased the throws mechanically. And i have also changed the mixes (do not know if this changed anything).

But, I can recall, at first, a 12 minute flight, whereby I practiced the Sportsman sequence 3 times, was consuming about 200 to 250 Mah per battery.

In the past 2 weeks, i recall now seeing that it was 600 mAh per battery, meaning 1200 Mah, per 12 minutes, or 100 Mah per minute of flight.

The airplane has JR MP 82T HV servos, and 2 sets of IBEC, the number of servos is 9.

I got some advice this weekend, and this is what I did:

I obtained a voltmeter, and made a lead, whereby I tapped the red lead of the servo extension, and this went thru the amp meter.

I then proceeded to measure each individual servo, and this graph demonstrates the results:

One thing i want to say is, that these servos are very quiet, they do not buzz, unless they are binding significantly.

but clearly it is evident that my ailerons servos and rudder servos were binding.

The measurements of one wing were made, one servo first, then adjustments made, then the other servo was measured, therefore, I do not know how much more the other servo was off, since the "bind" was addressed prior to making that reading.

Overall, the telemetry helped me, in that, I was able to discover there was a binding issue.

right aileron root servo, when deflected, was drawing 15 times more than when it was deflected the opposite direction. The left root aileron servo was drawing 5 times more one way compared to the other way. The right rudder servo was drawing 2 times more one way, than the other way. It will be interesting to see what happens on the next flight. I will report back!

I have changed out the 3 blade prop for a 2 blade, and huge difference in pull, This bird can climb on up-lines no problem at all now. It is a bit faster on horizontal speed. No problem with slowing her down for landings.

Here is the data:

flight date: 5/23/2015

flight number # 114 on the DA 200

number of gallons thru engine = 40

Engine: DA 200 ML

Fuel / oil mix: 50:1 redline

altitude: 260 feet

ambient temperature: 85 F

prop size: Falcon 30 x 14

air frame: DALTON 300 ML

radio system: JETI

data:

1. high temp during flight (not after landing):

RIGHT REAR CYLINDER 240.6 F Temp max during flight, average temp 214 F

LEFT REAR CYLINDER 227.3 F temp max during flight, average temp 205 F

RIGHT FRONT CYLINDER 292.2 F temp max during flight, average temp 275 F

LEFT FRONT CYLINDER 294 F temp max during flight, average temp 270 F

2. temp range (see 1 above)

3. rpm range 1500 to 7140

4. rpm max during flight 7140

5. rpm max on the ground 6000

6. Rx voltage 7.8

7. Rx voltage minimum during flight 7.6

any unexpected events: (list any info, like deadstick, etc....) NONE

this is telemetry data with a prop change, now a 2 blade Falcon 30 x 14

Here is the data:

flight date: 5/23/2015

flight number # 114 on the DA 200

number of gallons thru engine = 40

Engine: DA 200 ML

Fuel / oil mix: 50:1 redline

altitude: 260 feet

ambient temperature: 85 F

prop size: Falcon 30 x 14

air frame: DALTON 300 ML

radio system: JETI

data:

1. high temp during flight (not after landing):

RIGHT REAR CYLINDER 240.6 F Temp max during flight, average temp 214 F

LEFT REAR CYLINDER 227.3 F temp max during flight, average temp 205 F

RIGHT FRONT CYLINDER 292.2 F temp max during flight, average temp 275 F

LEFT FRONT CYLINDER 294 F temp max during flight, average temp 270 F

2. temp range (see 1 above)

3. rpm range 1500 to 7140

4. rpm max during flight 7140

5. rpm max on the ground 6000

6. Rx voltage 7.8

7. Rx voltage minimum during flight 7.6

any unexpected events: (list any info, like deadstick, etc....) NONE

this is telemetry data with a prop change, now a 2 blade Falcon 30 x 14

Last edited:

bigblueswope

100cc

Interesting data Ortho. Thanks for sharing. The servo binding was neat to learn.

BJ Swope

BJ Swope

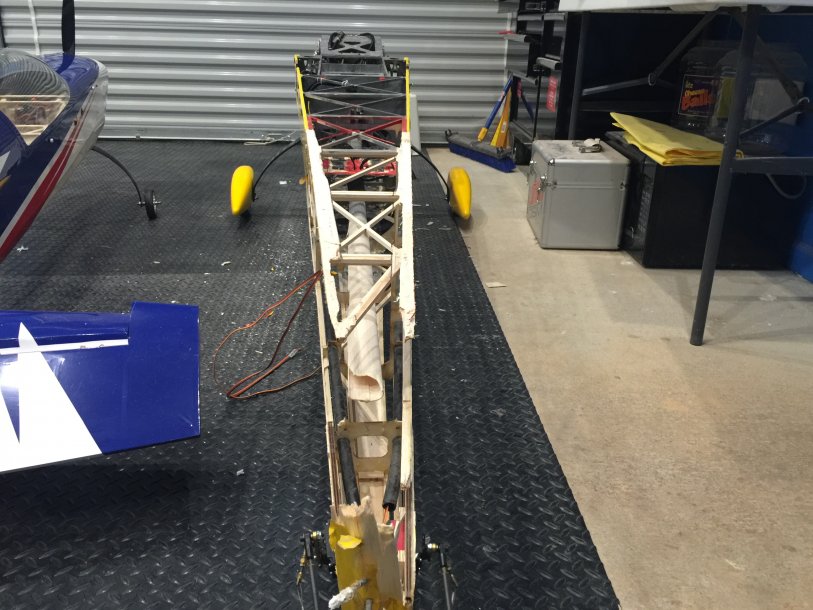

This photo was taken 2 weeks ago this past friday. took me time to accept what happened. But now I can talk about it. 30 minutes after this picture was taken, the dumb mistake occurred.

That Friday, in Sherman, Texas, preparing for the 19th annual IMAC contest, i was practicing. I did 3 practice flights. All was good. Then we took this picture, and i went to do a 4th practice flight. The 4th flight was highlighted by my best flying of the day. I did three sequences, and then prepared for my landing. I went to southside of the runway, as the wind was coming in from the North. There was a fence, and I was making sure to clear this, but I was way out further than i thought. The airplane was in landing mode, throttle was all the way down, and at low idle.

Unbeknown to me, the trees were closer that I thought, Or should I say, I was way out there.

That Friday, in Sherman, Texas, preparing for the 19th annual IMAC contest, i was practicing. I did 3 practice flights. All was good. Then we took this picture, and i went to do a 4th practice flight. The 4th flight was highlighted by my best flying of the day. I did three sequences, and then prepared for my landing. I went to southside of the runway, as the wind was coming in from the North. There was a fence, and I was making sure to clear this, but I was way out further than i thought. The airplane was in landing mode, throttle was all the way down, and at low idle.

Unbeknown to me, the trees were closer that I thought, Or should I say, I was way out there.

The tail was ripped off, one stab has some damage, the other stab, no damage, the fin is gone. Both wings got some damage.

Luckily for me, I had purchased this kit, and then decided to order from Tony the pre0sheeted parts. Thus, I have all the parts to replace the wings, turtled deck, fin, and stabs.

Just need a few parts to to do the repair.

I have already ordered these parts and as well as a new kit! I will build another 300 ML, but this time, completely per plans, and hope I can get a 43 pound airplane, instead of 46 pounds.

Luckily for me, I had purchased this kit, and then decided to order from Tony the pre0sheeted parts. Thus, I have all the parts to replace the wings, turtled deck, fin, and stabs.

Just need a few parts to to do the repair.

I have already ordered these parts and as well as a new kit! I will build another 300 ML, but this time, completely per plans, and hope I can get a 43 pound airplane, instead of 46 pounds.

I was able to carefully remove the turtle deck, it is possible i can re-use it!! awesome. I was impressed at how well fixed this was. It was an incredible glue joint! The poly u glue had amazing adherence, and I had to use a saw blade to break the interface. Then i was able to get a planer and remove the balsa from the top of the fuselage. then i sanded it smooth. I was considering removing the motor and all else, but after doing this, looks like i can totally work around all that. I will just cover the stingers and carb with tape so no dust can get in.