I am interested in optimizing the cooling of the motor, and am concerned with regards to overheating of the rear two cylinders. this being my first 4 cylinder RC airplane. the last time i worked on a flat 4, it was in 1986. It was an air-cooled 1.6 liter air cooled flat 4 (boxer) type engine. I did a complete rebuild on it. That is a different story. My research or should i say, my reading, has led me to believe that cooling of the rear cylinders is critical to prevent problems and prolong the longevity of my motor. I have come across multiple different baffling set ups for a 4 cylinder, this includes different strategies, such as a closed off rear cowl area, that directs air down thru the fins into the bottom of the cowl, using a split baffling type system.

http://www.google.com/url…

another technique is to use a NACA duct.

http://en.wikipedia.org/wiki/NACA_duct

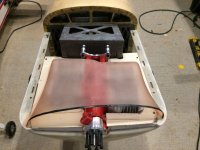

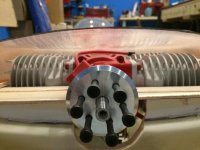

in reading the trumpet man's Dalton build, he came across something built byHenry Piorun for Cardens, that is a Shroud type of baffling. Still using the concept of the split cowl baffles, the shroud helps to direct air back then down thru the plate and the fins of the cylinders, then down and out of the air dams on the bottom of the cowl. I am not done yet, but these are some pics so far!!

With the split cowl baffle plates. trying to keep at least 1/8" gap between the fins and the plywood.

the superimposed shroud, which is for a Carden. It required modifications in order to fit.

I will be using 4 temp sensors, one on each cylinder. This will be important for me during the first few flights to assure that the temps are not getting high in the rear. From what i have read, using the shroud, the rear cylinder temps are lower than the front ones. I do not know if this is true, but we will see. Traditionally, the rear cylinders would run hotter since they are in the shadow of the prop wash (in a situation where no baffling was performed).

keeping in mind the rule of 3 to 1, i have built 4 air dams, two under the cowl using the epoxy material from the cowl itself, instead of cutting it out, i just made 3 cuts and pushed it down, opening to rear. then in bottom of fuselage, there will be 2 more air dams.