Naughty Monkey

100cc

He is probably honored! I had visions of cartwheels down the runway, but looks like it's OK. I was going to say that now it is dinged, you can relax and fly the snot out if it, but I have a feeling you already do!

He is probably honored! I had visions of cartwheels down the runway, but looks like it's OK. I was going to say that now it is dinged, you can relax and fly the snot out if it, but I have a feeling you already do!

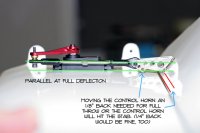

Great build man! Would you mind doing a quick video on your aileron geometry? I'm trying to wrap my head around it. Lots of info in that post.

Great information and video!