I spent quite a bit of time on the covering since there is a lot of covering over top of covering I used a fresh xacto knife to pop the little bubbles and smooth them out. Came out great!

**

TIP! - here is one not many people know about.... Ever have your plane out in the sun and your ailerons are all puffed up, then take it home and the covering is all wrinkled? Or you have one spot that is wrinkled and as soon as you heat it the aileron puffs up and the whole thing gets wrinkled?? Here is what you do - Take a 1/16" drill bit and drill a single hole in the bottom of the rudder, root side of the ailerons and elevators. No more pressurized surfaces!!

I hinged with 30 minute epoxy, to lube the hinges I like to melt some petroleum jelly and dip the hing point into it from both sides, place on towel so it does not run on the part that gets glue.

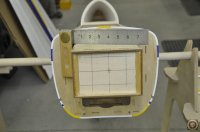

Time to mount the engine! If you are putting a DA70 in this plane you will need 1 1/8" engine standoffs. Little measuring and marking, drilling and I installed with 6mm bolts, SWB standoffs, fender washers (don't use standard size washers behind the firewall!!!) and nylock nuts.

**

TIP-2 - For ANY ARF assembly, make sure to chase ALL blind nuts with a tap before installing a bolt!!! China blind nuts are stamped so sometimes they need a little chaser to clean them up. Also sometimes glue can get in there during assembly at the factory.

Next I pinned the firewall by drilling small holes, harden with CA and install servo screws.

I decided to use the stock tail wheel, it is a perfect size for this plane, no problems rubbing the rudder when harriering on the deck. The little screws for assembling the tiller arm to the rudder are fine, but a little small so I like to use 7/16" servo screws. For springs I buy them from McMaster Carr and install them with some fishing line swivels, either #2 or #3 in size. Quick, easy and nice if you need to service them.

Gear is installed. Stock wheels are just fine, but I fly on a LOT of different fields so I prefer a 4" wheel on this size plane. I will put the gear cuffs on later, I just bolted the wheels on in case I need to get the plane off the stand for any reason. I'll install the cuffs and pants towards the end.

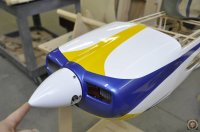

NOTE: I am getting asked this a few times, and YES I can confirm that the DA70 fits in this cowl with a solid 1/4" of space from the plug cap to the inside of the cowl