Pistolera

HEY!..GET OUTTA MY TREE!

Time to get the saw back out and cut some more on this airplane  .

.

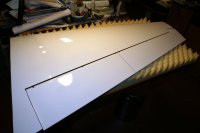

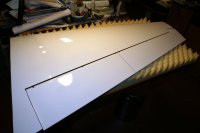

This is probably the farthest deviation from scale, but I decided a while ago that I would split the ailerons into 2 sections each. A couple of reasons why;

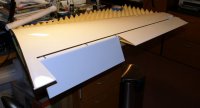

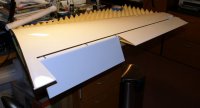

These shots show the various flight conditions;

More to come.

.

.This is probably the farthest deviation from scale, but I decided a while ago that I would split the ailerons into 2 sections each. A couple of reasons why;

- short "outboard" ailerons have been incorporated into the wings of many high-end IMAC planes like Cardens, etc. The theory is they tend to not disturb the airflow over the elevators in rolls and rolling circles while still giving plenty of authority for precision flying. I've flown a few and they work.

- I still wish to retain the full ailerons (using both sections together) for more radical roll rates/3D etc.

- The inboard sections can be used as flaps for short fields and/or approaches over treelines, etc. I've flown an Extreme Flight 104 Extra and could fly it at a fast walking speed with the flaps down, without being in a harrier

- They can also be used in a spoiler mode to dump lift, or in a crow mode (inboards up and outboards down) for very slow vertical downlines. This was fun to play with when I had my Beast.

- Servo matching is a thing of the past, as each servo only drives its own surface.

- Because I can!!!!

These shots show the various flight conditions;

More to come.

. The buttons BTW, go towards the fuse on the ailerons/elev, and the bottom on the rudder.

. The buttons BTW, go towards the fuse on the ailerons/elev, and the bottom on the rudder.

. You can see them hanging below each wing in this shot. They attach to the aileron and are angled forward of the hinge line so that when the aileron is deflected the triangular plate takes a "bite" into the slipstream, providing a force to help counteract the aerodynamic forces trying to push the aileron back into alignment with the slipstream. Simple but very effect.

. You can see them hanging below each wing in this shot. They attach to the aileron and are angled forward of the hinge line so that when the aileron is deflected the triangular plate takes a "bite" into the slipstream, providing a force to help counteract the aerodynamic forces trying to push the aileron back into alignment with the slipstream. Simple but very effect.