Bipeguy03

150cc

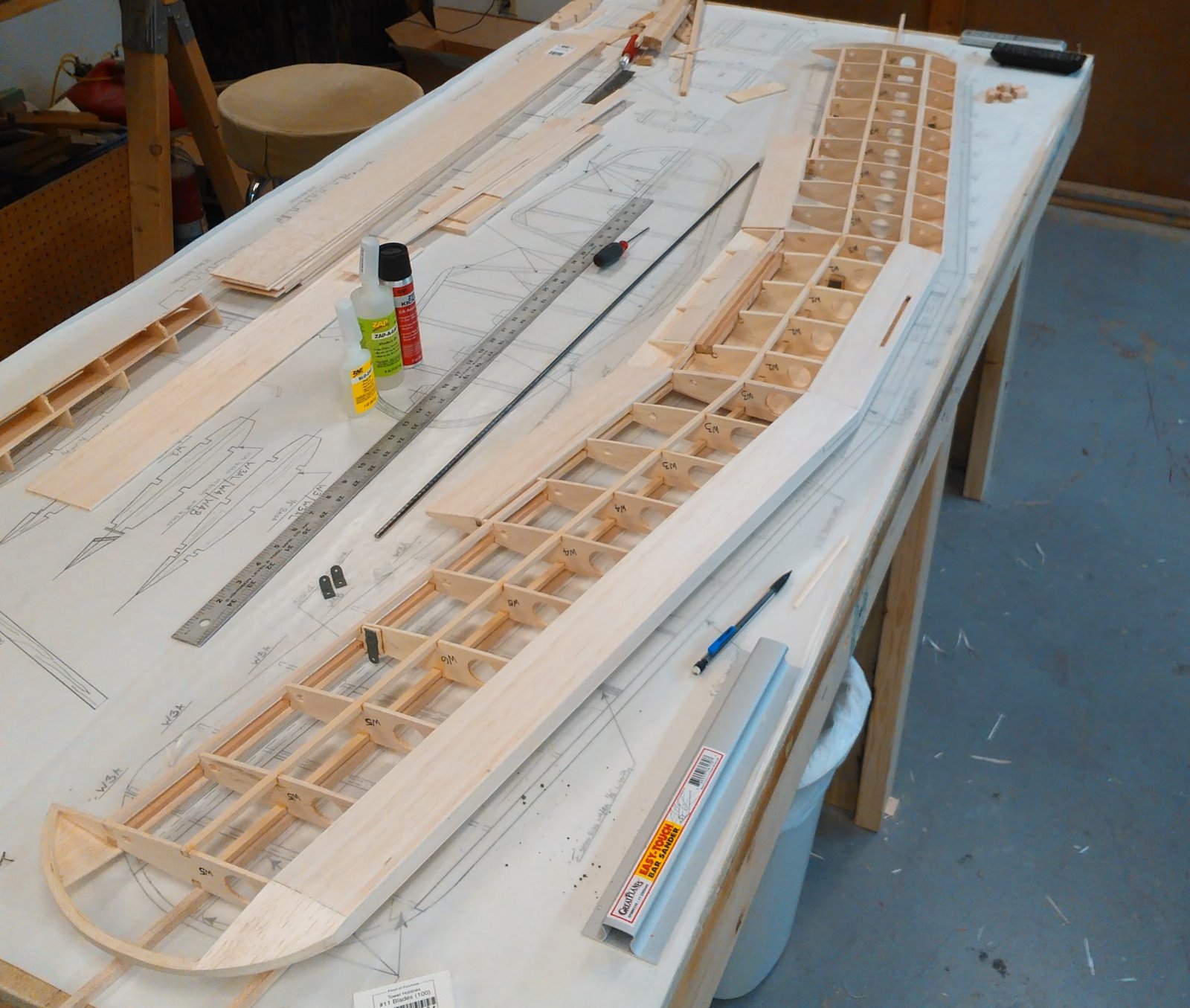

Finished putting in the flying wire tabs and started putting the sheeting on the bottom of the wing. Once the sheeting on the bottom of the wing is done I can put the leading edge cap on get it rounded off. The Servo bays and the ailerons will follow.

Attachment block for the flying wire tab near the fuse.

Flying wire tabs through the top of the sheeting, these will be on either side of the fuselage.

Flying wire tabs.

The outer flying wire tab near the N strut attachment.

Sheeting the bottom of the wing.

Attachment block for the flying wire tab near the fuse.

Flying wire tabs through the top of the sheeting, these will be on either side of the fuselage.

Flying wire tabs.

The outer flying wire tab near the N strut attachment.

Sheeting the bottom of the wing.