AKNick

640cc Uber Pimp

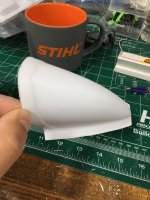

Control rod guide tubes installed.

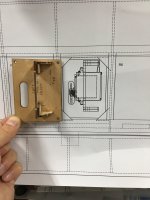

Mine ended up 25mm fwd of the fwd blind nut, and about 7.5mm from the edge of the lower ply skin.

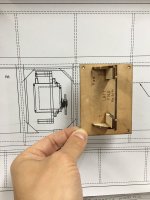

I ended up with a gap in the exit holes and used UV glue to fill it. Set in place with CA as it doesn’t bind to the tube that well.

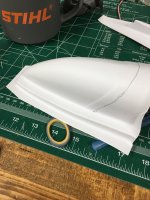

Elevator and rudder bulkhead holes had to be reamed out as well.

The rods and tubes were filthy. Cleaned the tube by spraying with silicone and a paper towel wadding rammed though.

The rods were cleaned to a mirrored finish with CLP cleaner. Good enough for my guns, good enough for these!

Mine ended up 25mm fwd of the fwd blind nut, and about 7.5mm from the edge of the lower ply skin.

I ended up with a gap in the exit holes and used UV glue to fill it. Set in place with CA as it doesn’t bind to the tube that well.

Elevator and rudder bulkhead holes had to be reamed out as well.

The rods and tubes were filthy. Cleaned the tube by spraying with silicone and a paper towel wadding rammed though.

The rods were cleaned to a mirrored finish with CLP cleaner. Good enough for my guns, good enough for these!