You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale 112” - Taylorcraft by HeyLuc & Snoopy.

- Thread starter Snoopy1

- Start date

Snoopy1

640cc Uber Pimp

JR sucks bad on info. They have some really good stuff but they never tel you about it and difficult to get info. I have the manual which came with the receiver/ power distribution unit.Nice, was looking to download the manual but couldn't fin it online. Just curious does the receiver load share battery 1 and 2?

It has two receivers in it and can fly on any of the two. And uses the one with the best signal.

It two battery in puts and will use the one with the highest voltage but is able to shut one down and fly on the other.

You can also add 2 satellites one to each receiver in the unit.

It has 16 channels and can be setup to be 8 ch- XBus and 8 ch - PWM. 16 ch XBus or 16 ch PWM.

It also has a bunch of internal telemetry that it sends back to the radio.

Please note do not know all it’s abilities just got it not much info on the unit out there.

Snoopy1

640cc Uber Pimp

@TonyHallo . Hi Tony. Just asking your opinion. Still trying to make a good fitting template for the windshield. I am really close but not happy as of now. My question to you is. If I made front windshield similar to a Beaver. I was at a friends house rebuilding a carb for him today and was looking at his Beaver. The Beaver windshield does not wrap over the top. The windshield kind of goes across the front. Much easier to make. I will not put the center post in. Just enclose the top section with balsa and do a windshield across the front. I believe I can make really nice job of it. Your input would be appreciated.

TonyHallo

150cc

I watched this video recently on fitting windshields. The author kind of used your idea of fitting the windshield from posts to post then adding on the upper section. I experienced the same issue he had where you can make a perfect template but the PETG just doesn't bend like the template material. I used SeeTemp on the last windshield I fitted and held the upper portion with #0 screws. Like so many things in this SeeTemp is no longer available, I learned last week that Robart has ceased making landing gear products, guess I will need to make my own struts in the future.

At any rate the problem becomes that you need to use a thinner PETG to make the tight bend in the upper corners that the flat front area is weak, I would not eliminate the center post. The Cessna windshield below flapped from the prop blast but plane only lasted on flight due to a knock off Deans connector.

At any rate the problem becomes that you need to use a thinner PETG to make the tight bend in the upper corners that the flat front area is weak, I would not eliminate the center post. The Cessna windshield below flapped from the prop blast but plane only lasted on flight due to a knock off Deans connector.

Snoopy1

640cc Uber Pimp

Thanks for that it was helpful, watched the video it was in formative and helpful. Been working on a new windshield template.I watched this video recently on fitting windshields. The author kind of used your idea of fitting the windshield from posts to post then adding on the upper section. I experienced the same issue he had where you can make a perfect template but the PETG just doesn't bend like the template material. I used SeeTemp on the last windshield I fitted and held the upper portion with #0 screws. Like so many things in this SeeTemp is no longer available, I learned last week that Robart has ceased making landing gear products, guess I will need to make my own struts in the future.

At any rate the problem becomes that you need to use a thinner PETG to make the tight bend in the upper corners that the flat front area is weak, I would not eliminate the center post. The Cessna windshield below flapped from the prop blast but plane only lasted on flight due to a knock off Deans connector.

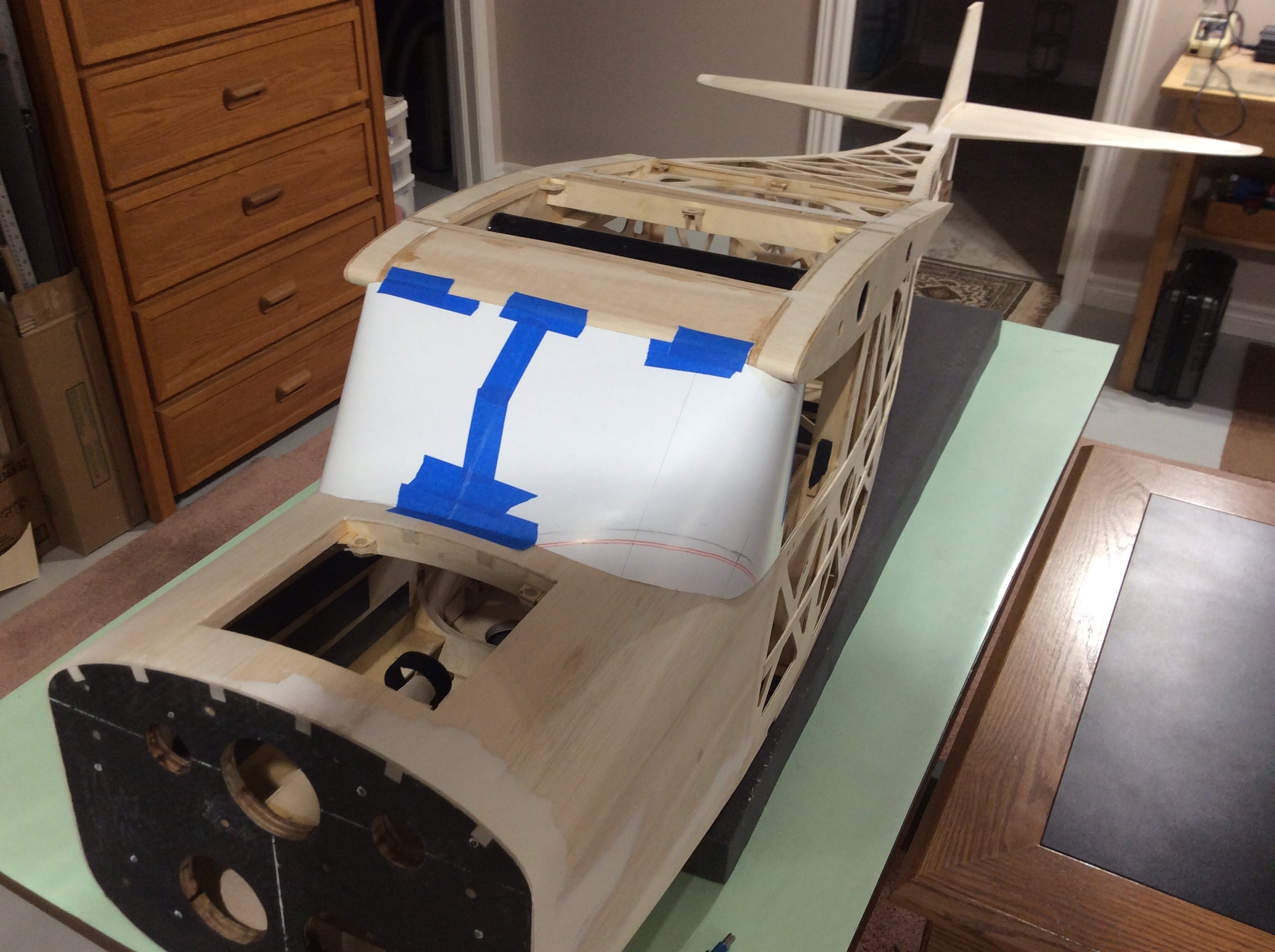

View attachment 122403View attachment 122404

Still trying to get my hands on some windshield material it is turning out to be quite difficult. The size I need is the problem need 11 by 24 inches. It’s the 24 inches that is the problem I may have to split the windshield into two parts really do not want to do that but it may be my only solution.

Snoopy1

640cc Uber Pimp

Changes made and a new template made. It took a few tries but this one looks good and all fits. But I do know that when I get my hands on some windshield material I can continue. I also know the plastic well NOT shape and bend like cardboard so it will most likely need to be refitted but I am close now.

Snoopy1

640cc Uber Pimp

I am trying to get 0.30” and ordered that thickness. I hope that it is the correct thickness. It seems 0.020” is easier to get. Hopefully I get confirmation that they managed to get it for me tomorrow.What thickness are you trying to get? .02 or .03"?

Snoopy1

640cc Uber Pimp

Well called the person about the windshield material, does not have it, he said he needs another week to have the material. Starting to run out of things to do. I am having doubts if I will scratch build another plane, it is becoming difficult and impossible to get all the bits and pieces to build a plane. There was a time you take run to the local hobby store get almost anything you needs if not he could order it, within week. Starting realize why the hobby is dying difficult to get stuff and no local hobby shops to go to and walk around and see the latest stuff.