You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale Wendell Hostetler 30% PA-28 Cherokee Build

- Thread starter TonyHallo

- Start date

TonyHallo

640cc Uber Pimp

I'm putting the final touches on the Champ fuselage pinking tapes, I keep starring at the Cherokee plans hanging from the ceiling. I'm giving serious thought about making a mold of the fuselage and laying up the next one. This would be a serious mold. This would allow making a detail interior very scale like with an operating door.

I have ordered a cowl and wheel pants from Fibertech N More. They have changed their business plan and are currently taking orders for Hostetler parts only, they state the change is due to their time constraints. I do enjoy their quality parts and hope they are here for the long haul. But it does make me wonder why? I would expect it takes the same amount of time to lay up a Hostetler Cherokee cowl as a Hurley Extra 300 cowl. I still remember my dad's saying when I would complain about him taking in another job an hour before we had planned to go home on a Saturday afternoon, "You got to make the hay while the grass is green". A backlog is healthy for a business and in many areas they are the only show in town.

I have ordered a cowl and wheel pants from Fibertech N More. They have changed their business plan and are currently taking orders for Hostetler parts only, they state the change is due to their time constraints. I do enjoy their quality parts and hope they are here for the long haul. But it does make me wonder why? I would expect it takes the same amount of time to lay up a Hostetler Cherokee cowl as a Hurley Extra 300 cowl. I still remember my dad's saying when I would complain about him taking in another job an hour before we had planned to go home on a Saturday afternoon, "You got to make the hay while the grass is green". A backlog is healthy for a business and in many areas they are the only show in town.

The Fibertech wheel pants are OK. But the cowl is strictly an early (1964) 140 Cherokee. Throughout the years Piper has probably used a dozen or more different cowls on the various models of that plane. The differences were driven by different engines, 4 and 6 cylinders and the cooling needs of those engines.

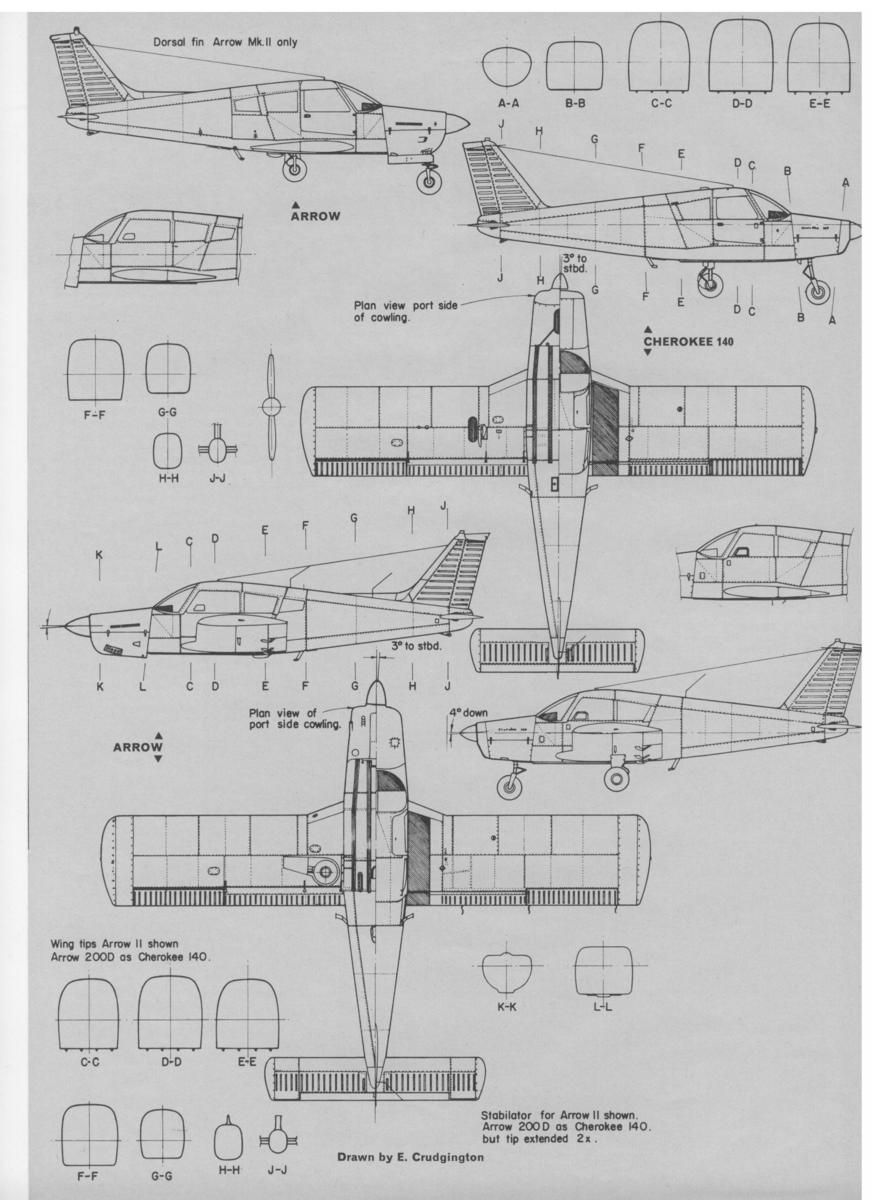

The engine on the real one has 3 degrees of both right and down offset. This is quite obvious when looking at the front of the cowl from above. Go to E-Bay and do a search for Piper Cherokee Fuselage. Lots of bits and pieces will result but the cowl pics will really show the effects of the engine offset. Pic attached below.

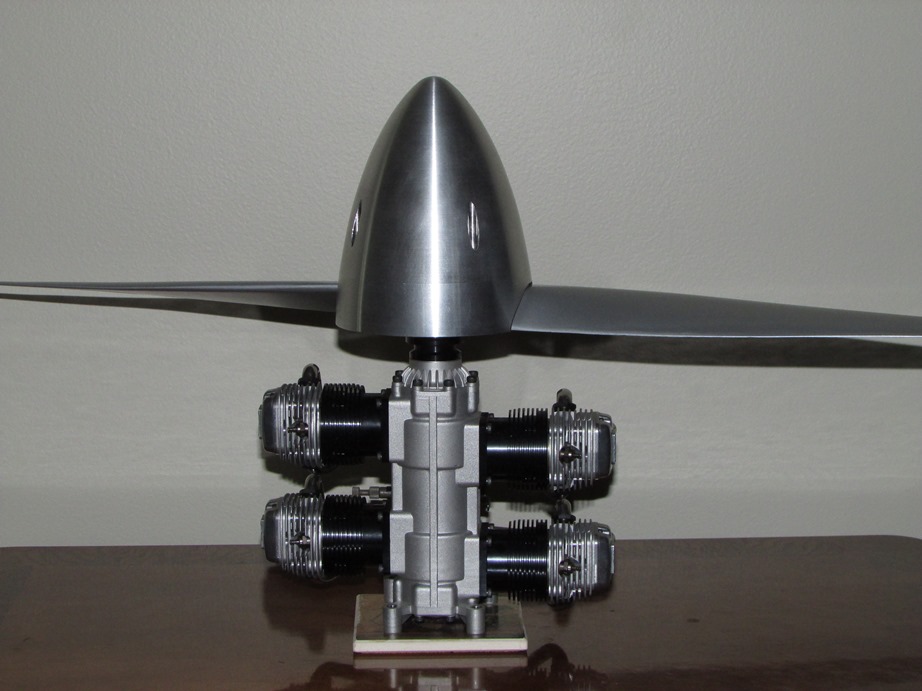

The spinner too is important as Piper used a number of different diameters, lengths and profiles as part of the cooling system. So pick your plane and research the spinner too. My particular one uses a 4.2 inch diameter by 5.4 inch long spinner. I had mine made by a fellow down under.

For a glass fuselage I would do a few things. I'd make just the front half in glass. This lends itself to making a two part fuselage for transport should one want to. Starting with the scale firewall in the front and going to F-5 on the WH Plans. I would also cant both the Firewall and F-5 seven degrees towards the rear as does Piper with the real one. Get a good side pic and follow the panel lines to locate the Firewall and F-5.

Going with the scale firewall location allows one to use an engine box or standoffs of approx 5 inches depending on engine. Or one can do like I am and slowly piece together a scale like steel tube engine mount.

I am converting WH Cherokee 140 to a more accurate scale Cherokee 180C. Like the one my Father owned way, way back. Health has greatly slowed my progress on it but I do have a ton of research should anyone have questions.

Pic of a 180 cowl top as seen from above. Of note is the right engine offset:

My spinner and a real one:

The engine on the real one has 3 degrees of both right and down offset. This is quite obvious when looking at the front of the cowl from above. Go to E-Bay and do a search for Piper Cherokee Fuselage. Lots of bits and pieces will result but the cowl pics will really show the effects of the engine offset. Pic attached below.

The spinner too is important as Piper used a number of different diameters, lengths and profiles as part of the cooling system. So pick your plane and research the spinner too. My particular one uses a 4.2 inch diameter by 5.4 inch long spinner. I had mine made by a fellow down under.

For a glass fuselage I would do a few things. I'd make just the front half in glass. This lends itself to making a two part fuselage for transport should one want to. Starting with the scale firewall in the front and going to F-5 on the WH Plans. I would also cant both the Firewall and F-5 seven degrees towards the rear as does Piper with the real one. Get a good side pic and follow the panel lines to locate the Firewall and F-5.

Going with the scale firewall location allows one to use an engine box or standoffs of approx 5 inches depending on engine. Or one can do like I am and slowly piece together a scale like steel tube engine mount.

I am converting WH Cherokee 140 to a more accurate scale Cherokee 180C. Like the one my Father owned way, way back. Health has greatly slowed my progress on it but I do have a ton of research should anyone have questions.

Pic of a 180 cowl top as seen from above. Of note is the right engine offset:

My spinner and a real one:

TonyHallo

640cc Uber Pimp

I do not understand your reasoning for canting the firewall, it is overlapped by the cowl by several inches so nobody is going to see it. It would also complicate mounting the engine. I used machined standoffs to set the right and down thrust. I already have a custom nose wheel bearing set at whatever angle was shown on the drawing, I assume it is 7 degrees as it matches the angle shown for the cowl on the WH drawing. I wasn't happy with the fit of the cowl on the previous build so that will be an area where I plan to spend more time.

As far as F5 I assume you are talking about F5A, I changed the angle on the previous build and made F5A match the angle shown on the drawing. See photo below.

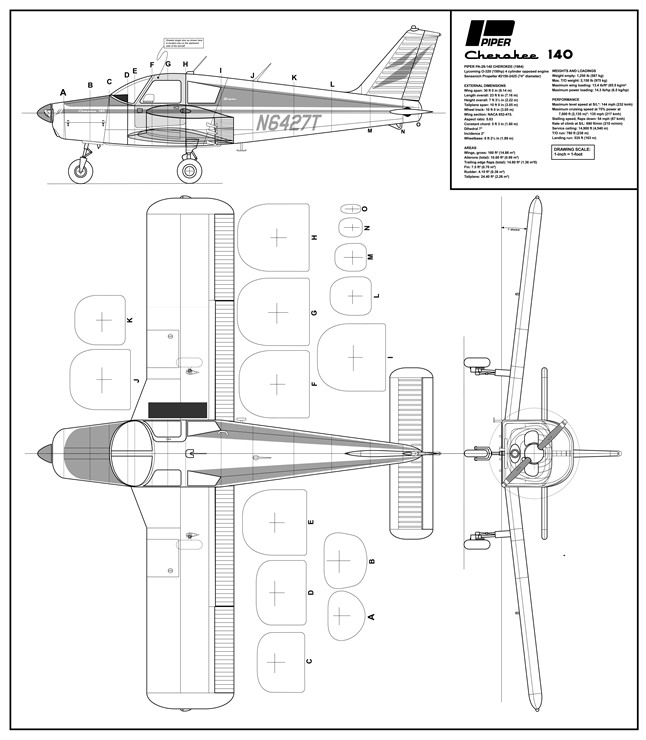

Once the mold is made if a person wanted a two piece fuselage that would be possible. Based on the three views I have the rear portion of the fuselage needs a little contour work. I can made this area out of thicker balsa and sand it to shape. I think I can do a better job with the shape by building the complete fuselage then glassing it for the plug. Do you an accurate three view with sections you care to share? I believe you told me the ones I have are inaccurate?

Thank you for your comments and input here.

As far as F5 I assume you are talking about F5A, I changed the angle on the previous build and made F5A match the angle shown on the drawing. See photo below.

Once the mold is made if a person wanted a two piece fuselage that would be possible. Based on the three views I have the rear portion of the fuselage needs a little contour work. I can made this area out of thicker balsa and sand it to shape. I think I can do a better job with the shape by building the complete fuselage then glassing it for the plug. Do you an accurate three view with sections you care to share? I believe you told me the ones I have are inaccurate?

Thank you for your comments and input here.

I'm canting the firewall simply because the real one is. I "attempt" to do what use to be called precision scale.

I don't have what I consider accurate drawings of the cross sections. The cabin sides under the windows I believe are nearly flat and become a little more rounded once behind the cabin. But not as rounded as the WH plans show. The curvature is about half of what WH shows. The second or lower 3 view you posted here has what I feel are the closest sections. The trick is to accurately enlarge them to model size. I'm not a CAD guy. Pencils and rulers for me. As for the last one in the tail to which a flying stab would mount to. I worked up an accurate section from pictures I got off E-Bay. Here's one of them. Did the same for the firewall.

It's been a while since I've worked any on my Cherokee. My health has kept me quiet for that last year or so

I don't have what I consider accurate drawings of the cross sections. The cabin sides under the windows I believe are nearly flat and become a little more rounded once behind the cabin. But not as rounded as the WH plans show. The curvature is about half of what WH shows. The second or lower 3 view you posted here has what I feel are the closest sections. The trick is to accurately enlarge them to model size. I'm not a CAD guy. Pencils and rulers for me. As for the last one in the tail to which a flying stab would mount to. I worked up an accurate section from pictures I got off E-Bay. Here's one of them. Did the same for the firewall.

It's been a while since I've worked any on my Cherokee. My health has kept me quiet for that last year or so