scruffmeister

50cc

(I wasn't sure if this should go in telemetry forum, or engine forum - I settled on engines as it's really a question about how to attach things to engine cooling fins).

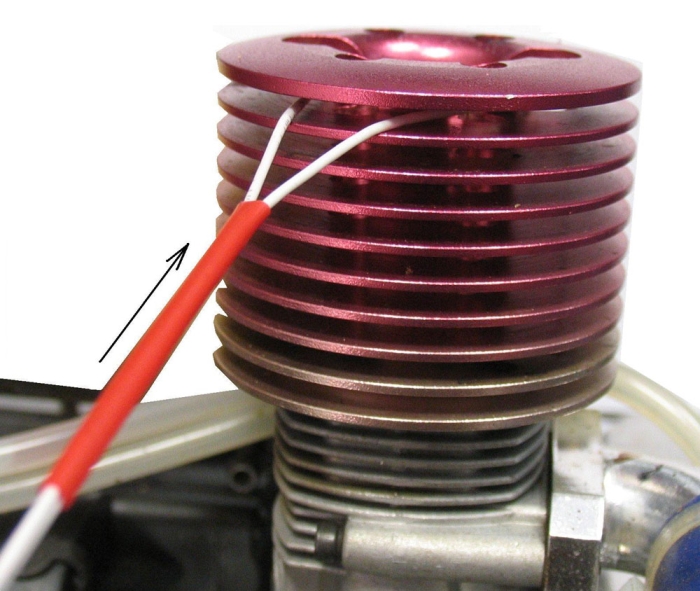

I have a temperature sensor I would like to attach to the cooling fins on my DA120. It has a lasso loop (see pic), but I can't get this tight enough to hold the sensor still once the engine is running - it slips around getting tangled up. So, I'd like to fix the sensor in place using an appropriate "glue" of some kind.

Has anyone got on tips on the best way to stick something like this on please? I was thinking maybe small blob of high-temp gasket sealant (copper RTV) on the wire/fin? Ideally I'd like the glue to be fairly easily removable in the future.

Cheers.

I have a temperature sensor I would like to attach to the cooling fins on my DA120. It has a lasso loop (see pic), but I can't get this tight enough to hold the sensor still once the engine is running - it slips around getting tangled up. So, I'd like to fix the sensor in place using an appropriate "glue" of some kind.

Has anyone got on tips on the best way to stick something like this on please? I was thinking maybe small blob of high-temp gasket sealant (copper RTV) on the wire/fin? Ideally I'd like the glue to be fairly easily removable in the future.

Cheers.