Okay... that was time consuming. First plane that has taken longer than a couple of minutes to work out. First plane I wasn't able to get ideal geometry, resolution, leverage, linearity and synchronization without a total makeover. Leverage and resolution I had in the 3 pics I showed up thread. But, I still hadn't put on a protractor to check synchronization and adjust for linearity.

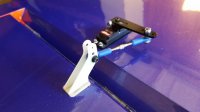

First... linearity. I was not able to get it with the ball link where I show it up thread in the 3 pics. With the ball link on the side of the stock control horns like that the best I could get was 7 degrees different, up vs. down, off of center. I was able to get equal travel (47 degrees up, 47 degrees down) by putting the ball links on the opposite side of the stock control horns (the outside instead of the inside). But, that left me with no leverage, and lots of pry load vs. side load. So, that was out. I ended up going with the stock ball link location at 6 degrees different, up vs. down, off of center as a compromise between leverage and linearity. Reason for not getting it ideal, like usual? The servo location. It's so close to the hinge line that the pushrods are very short (1-1/2"), so the angles get too severe. So, anyway, now, one of my ailerons will always be moving just a frog hair faster than the other one. Never have had that since I first figured all this out in like 2003. If I fall in love with the plane I could always, at any time, move the servos out another 2-1/2". If I did that it would end up ideal like all my other planes.

Next up... synchronization. Having the outboard servo traveling the same distance (104 degrees in this case) as the inboard servo in order to make the surface travel a specific chosen distance (13", in this case). I always get this with finely adjustable bolt style control horns, but never so far with factory located non bolt style control horns. This case was no different. I used the low hole for the inboard servo and needed 104 degrees of travel on the servo arm to achieve 6-1/2" of aileron travel up, and 6-1/2" of aileron travel down, from center. On the outboard servo I needed 108 degrees of travel to achieve the same 6-1/2" of aileron travel, up and down. At least it is only 4 degrees off, but the numbers let you know, that if anything, the middle hole should be slightly lower. So, for those that put in a middle servo in the middle hole, and the outside servo in the high hole... things would be way off.

So, now that I've returned to a normal stock setup... I'm only 6 degrees off on the linearity and only 4 degrees off on the synchronization.

Again, usually it doesn't go like this... with the servos out far enough to use 2-1/2" to 4" pushrods I'm usually setup all perfect in minutes. But, on this one I took some time to sort it out and realize that I couldn't get it perfect, but I could get it close.

But nice work Joe.