You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D Edge 540 Profile Build (Glitter JR)

- Thread starter BalsaDust

- Start date

BalsaDust

Moderator

BalsaDust

Moderator

At the root

That’s all for now. Might be a few days before my next post. We have family staying with us for the weekend.

pawnshopmike

Staff member

BalsaDust

Moderator

BalsaDust

Moderator

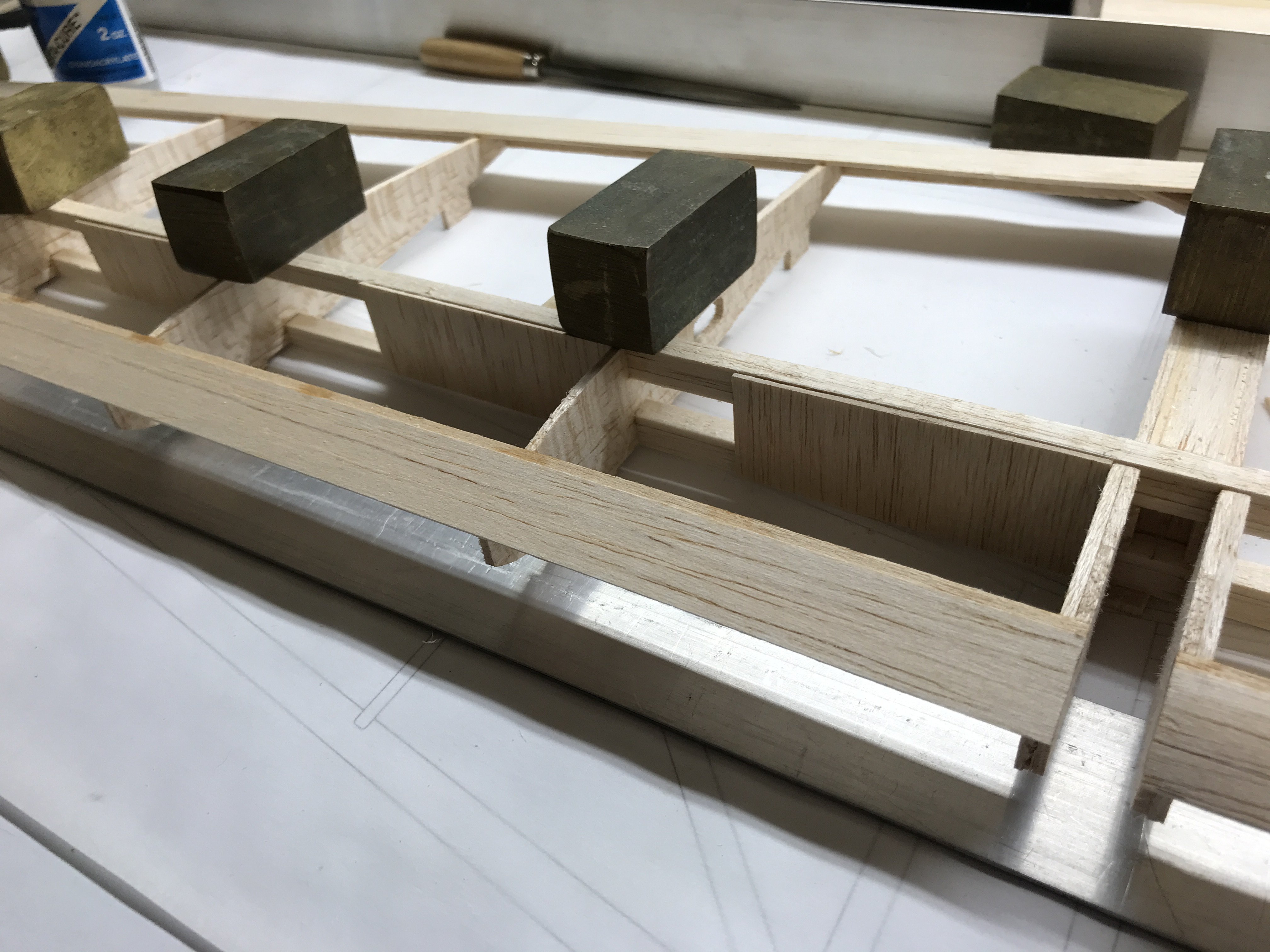

Well back in the flow of things and got a little work done this morning. First up was doing the LE sheeting. I just grabbed a sheet of 1/16”x3”x36” balsa and ripped it into four even 3/4” wide pieces. Mark the center line of the front subspar at each end and glue to this. I’m using softer balsa here so I was able to then just roll it over and glue it doen but if not just spray a little windex on it to help with the curve. The sheeting will overhang the LE of the rib just a bit bit that’s ok well will address that a little later.

After the le sheeting was done I moved onto the sheer webs. Again using 1/16 balsa 3” wide but I selected a little harder piece of balsa for this. I glue mine to the front of the spars and dont feel the need to fill the entire space, just be sure it’s flush to the inside rib.

After the le sheeting was done I moved onto the sheer webs. Again using 1/16 balsa 3” wide but I selected a little harder piece of balsa for this. I glue mine to the front of the spars and dont feel the need to fill the entire space, just be sure it’s flush to the inside rib.

on the otermost bay do the opposite having the sheer web butt up against the outer tip rib. This makes the tip s little stronger in the event of a tip strike.

on the otermost bay do the opposite having the sheer web butt up against the outer tip rib. This makes the tip s little stronger in the event of a tip strike.