I know it Rusty! I just went out to the shop and inspect it, and it came out real good. i did not take my cell, so i was not able to take a picture, I will tomorrow, when I do the ones for the other fuselage. Now time to read on how to build the fuselage sides. At this time, I am confused.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC Double Build, Carden Pro 124" Extra 300 40%

- Thread starter orthobird

- Start date

-

- Tags

- 40% airplane build thread imac

Bunky.F.Knuckle

150cc

By just having the cap screws in the bare wood, threaded, it will leave the gear plate in the fuse,if a gear out situation occurs, but will unfortunately poke holes in the bottom of the wings from the wheel pants. I am all too familiar with that. Be sure to harden the threades with thin super glue.From the manual: (the next step for me)

2. Drill Four #8 Holes in the Landing Gear Pilot holes in the L.G. Mount. Use a drill press. Mark and

drill through the L.G. Mount and ½” by ½” Hardwood with a #8 tap drill. Tap for 8-32 x 4 Socket Head Cap Screws. Nuts are not required.

this is what I did (so far):

used a ruler and a angle to determine where the landing gear needs to go, and then did measurements til i fugured out what was square.

View attachment 52843

i then marked where I thought, the holes would be or should be:

View attachment 52844

here it is, after drilling and tapping, and I am satisfied with this, however......

View attachment 52846

View attachment 52845

You can probably read my mind. I am itching to put an aluminum angle in there, with a aircraft quality plywood and blind nuts to finish it off. Just do not trust leaving that alone, but I am crazy like that....

View attachment 52847

Both of my 35% Extras were built that way, and trust me, is more than adaquete.

They came out well.

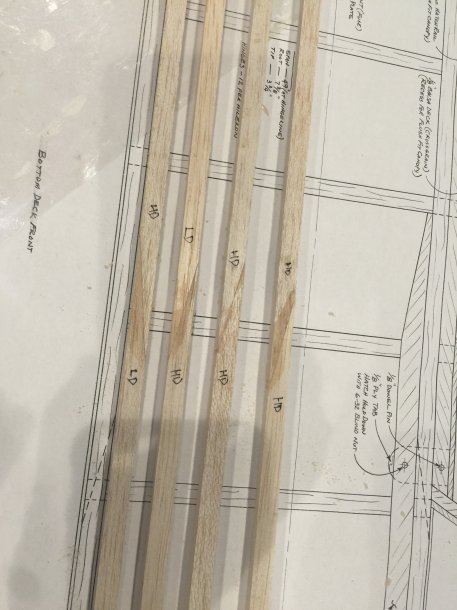

I marked HD for high density

and LD for Low, but really, they are just regular density.

The HD on both sides will be for the upper Longerons

and the hybrid sticks go on the bottom, with the normal density towards the back.

the scrap will be used for cross bracing as well.

Next step, is to obtain some form of wax paper or polyester film to cover the plans, and begin to build the truss fuselage sides.

I marked HD for high density

and LD for Low, but really, they are just regular density.

The HD on both sides will be for the upper Longerons

and the hybrid sticks go on the bottom, with the normal density towards the back.

the scrap will be used for cross bracing as well.

Next step, is to obtain some form of wax paper or polyester film to cover the plans, and begin to build the truss fuselage sides.

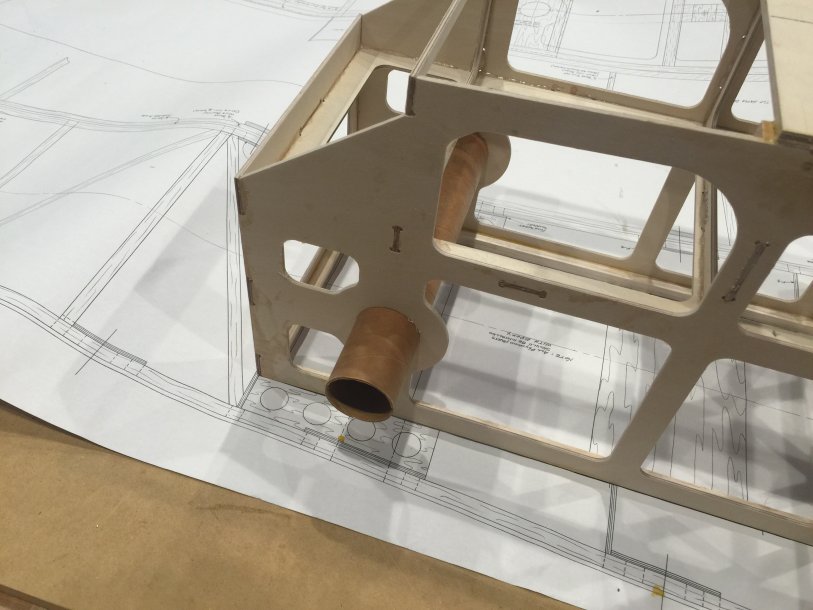

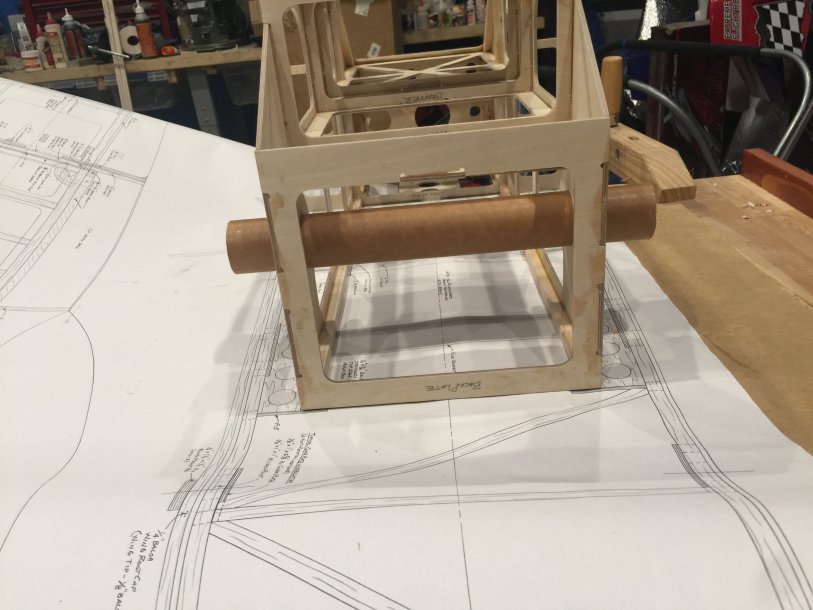

I had skipped a step:

3. Cut the 1 & 1/2" Dia. Socket to 12 & 1/8” for instalation in the Fuselage. Trial fit the Socket. Check and adjust if necessary for a square fit. Socket installation takes place in step #21.

not illustrated, but I used a right angle, and made measurements, to assure that the tube was square to the table top.

3. Cut the 1 & 1/2" Dia. Socket to 12 & 1/8” for instalation in the Fuselage. Trial fit the Socket. Check and adjust if necessary for a square fit. Socket installation takes place in step #21.

not illustrated, but I used a right angle, and made measurements, to assure that the tube was square to the table top.