stangflyer

I like 'em "BIG"!

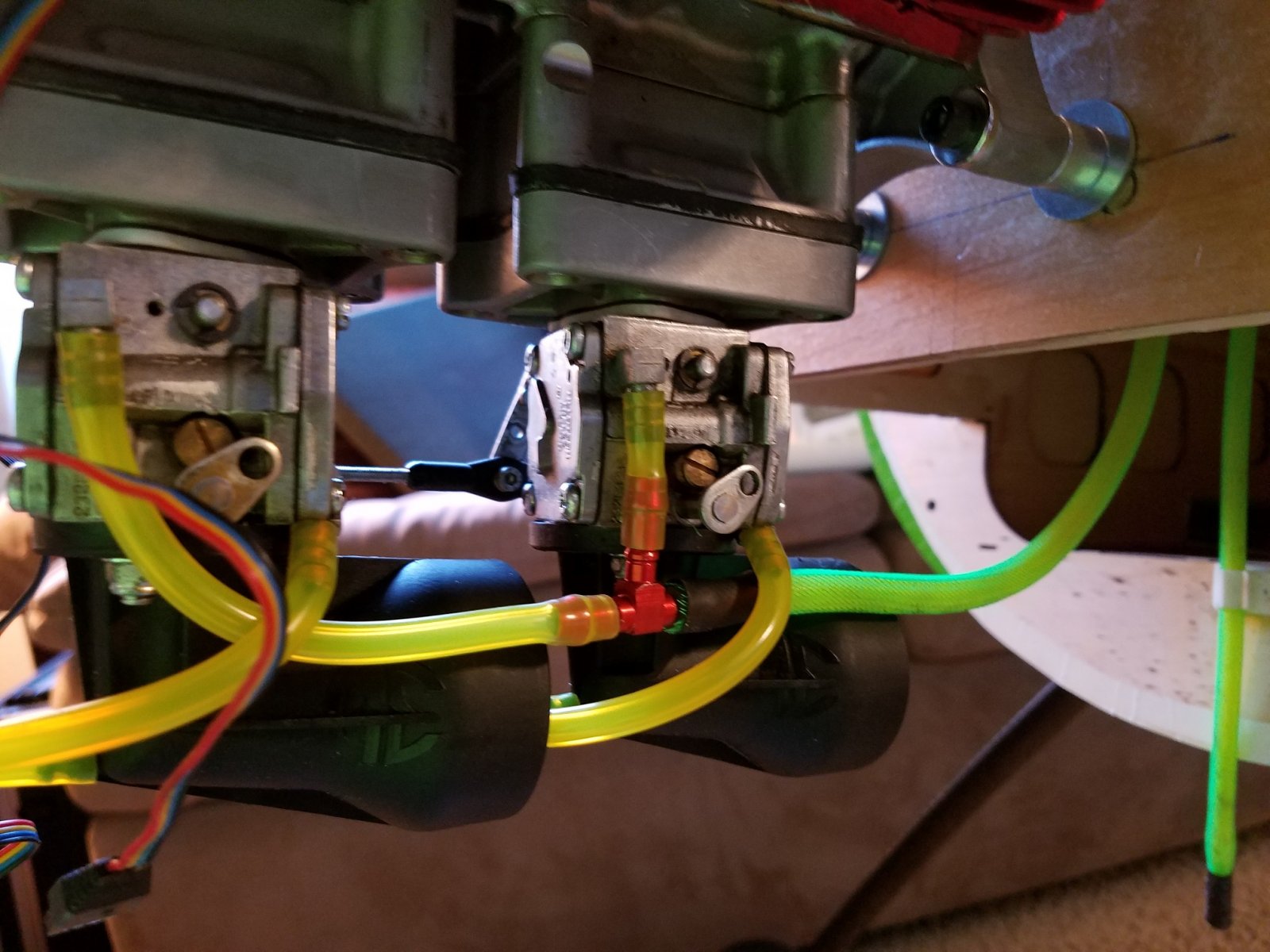

A little more progress of the install of the 212 on the Behemoth Yak. Long days at work are slowing the process, but a little each day and I should have it ready to button up soon. First, the fuel system is complete now. New vent tubing on the air horns along with new 5/32" fuel tubing from the tank to the carb split "T". New 1/8" Tygon after the "T" feeding each carb.

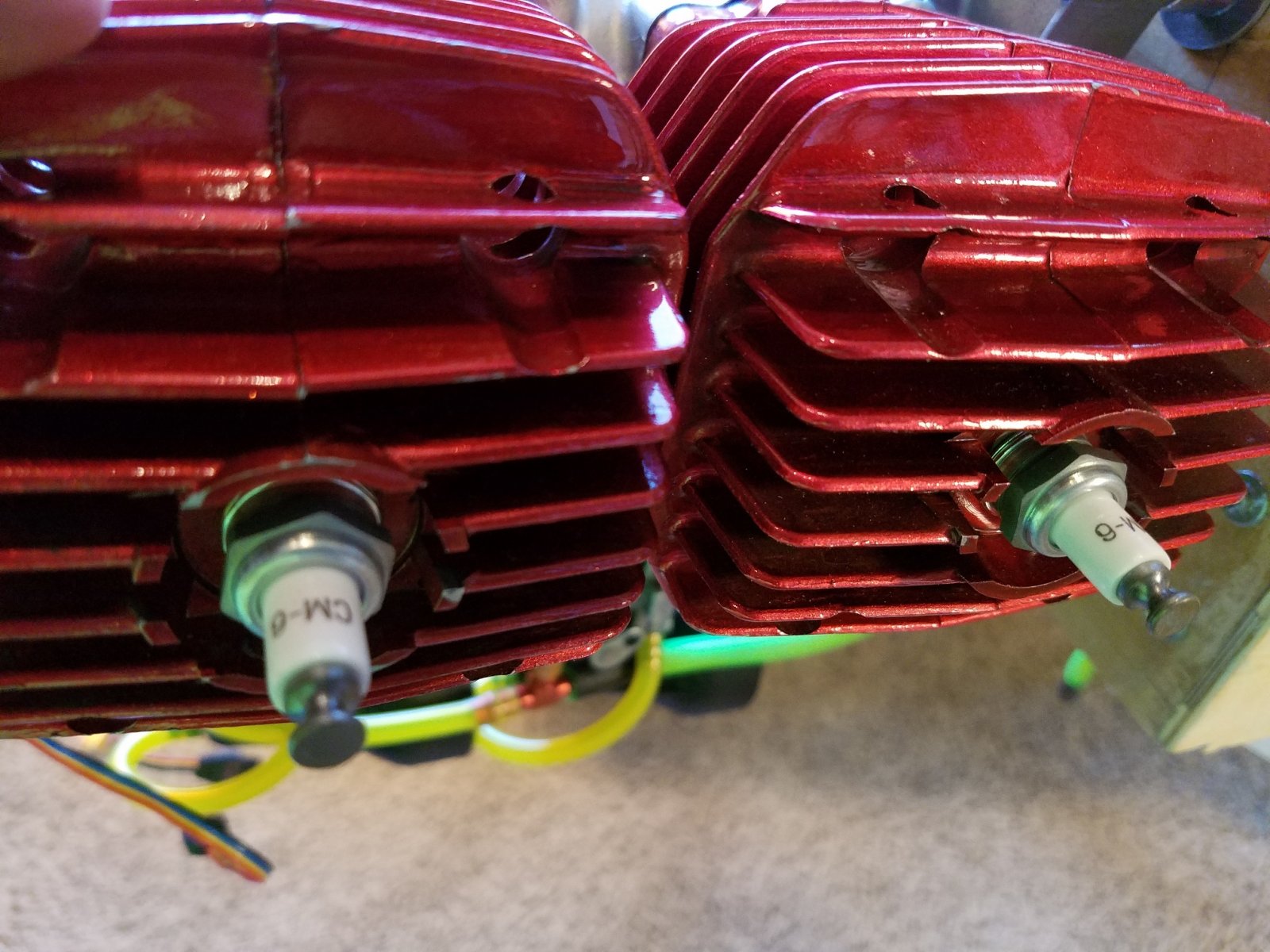

Next, four new NGK CM6 spark plugs gapped to .0185. One for each red head jug.

I needed to do a quick mock install of the headers to see where they were going to line up. For what ever reason, I got these dang things headed right down the can tunnel. They're supposed to be like this, right? LOL. I just remember the last time I had this engine on the Yak way back last year, the exhaust was so far away from going straight down the can tunnel. I am going to lay odds that with the rebuild after the mishap last year, everything got put back the way it was supposed to be. I dunno. I will order up the L80 canisters tomorrow. Hopefully they will be here by the time I am ready to install them.

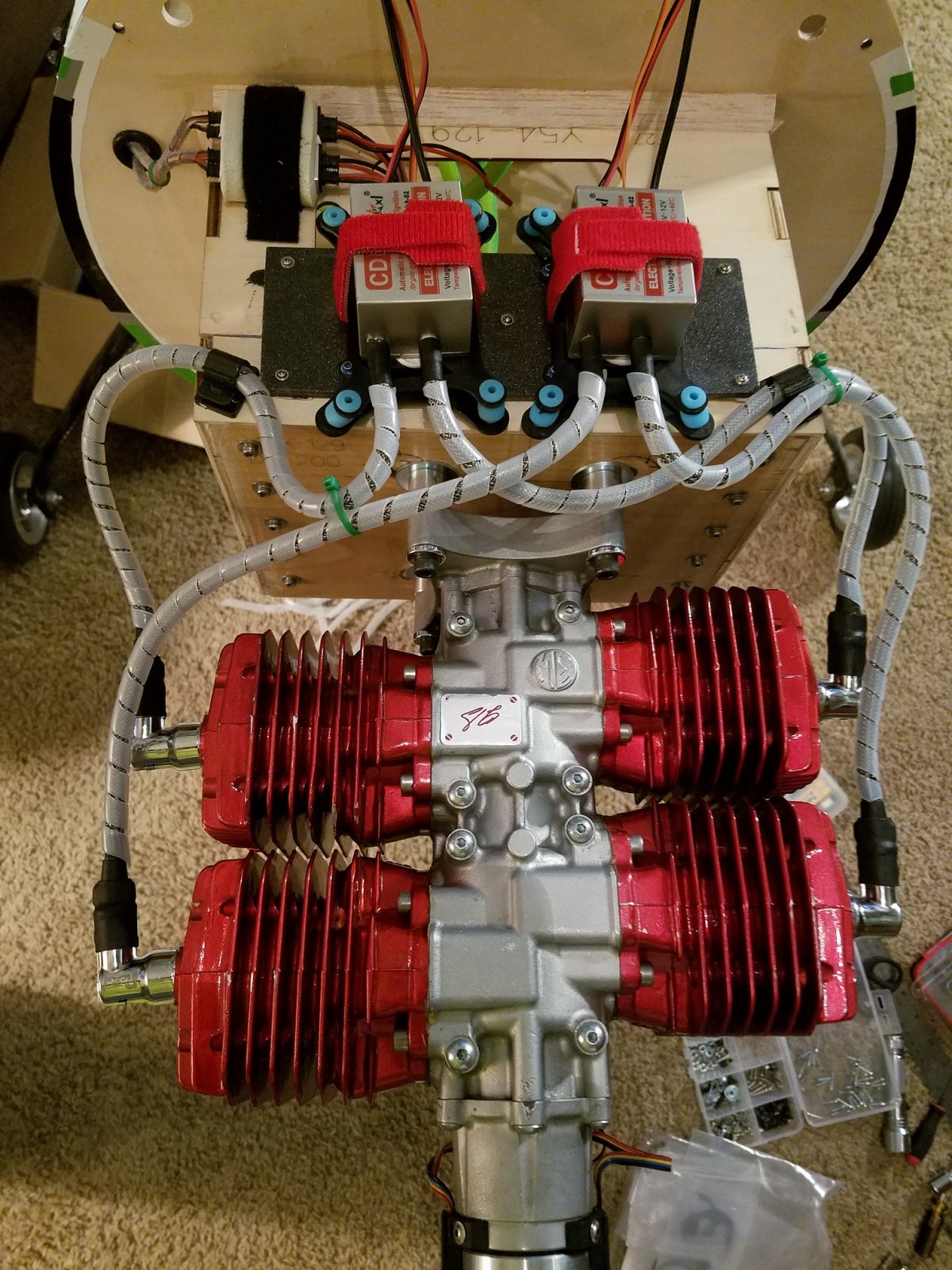

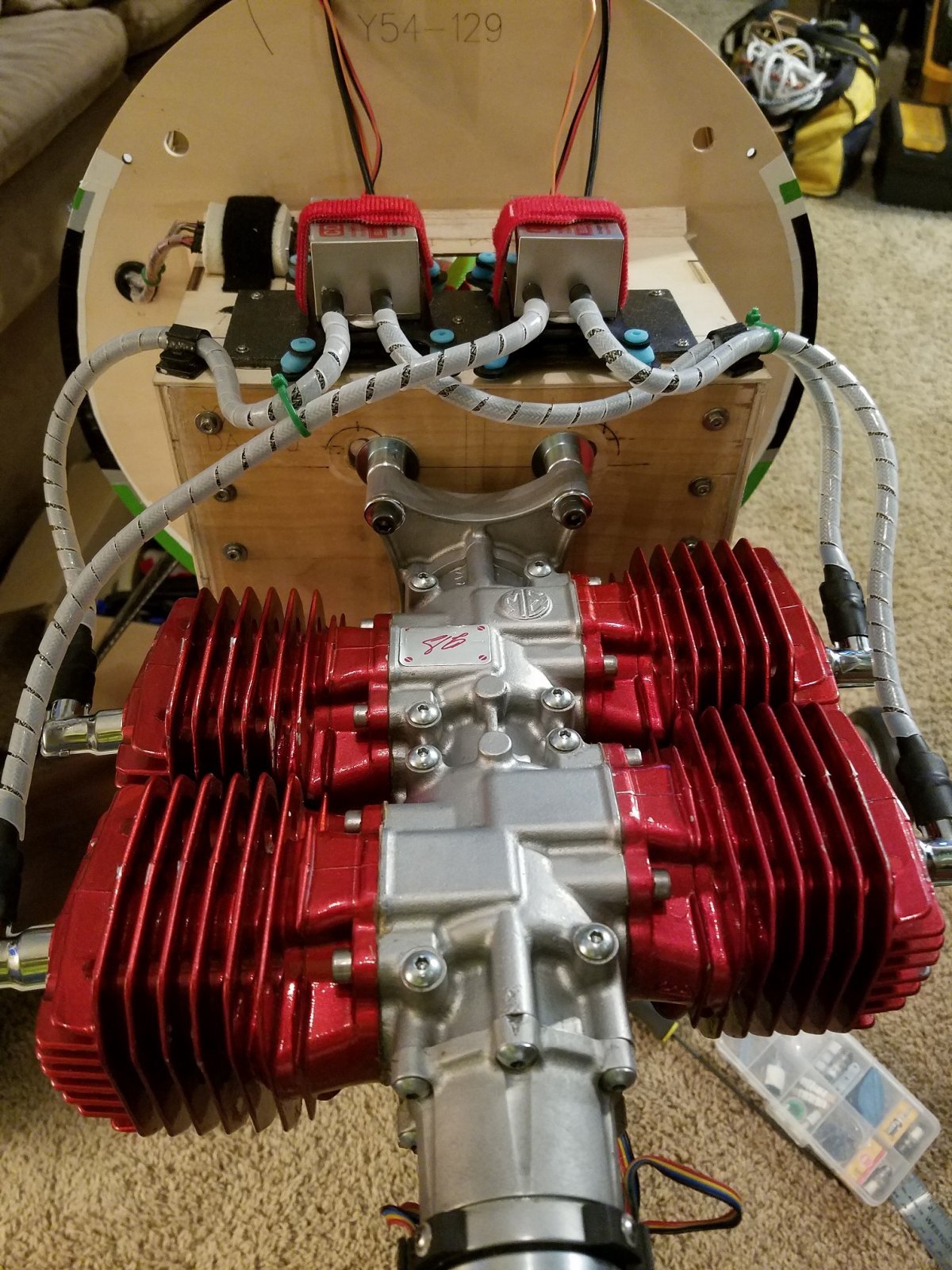

After the quick check of the exhaust headers, I mounted the Taildragger RC Ignition Module "Vibra Mounts". I saved the bolt plate from the 210csts twin install. It layed back into it's original position.

After the module mounts were installed, I installed the twin RC Excel Ignition Modules.

Once the module were in place, I went through the wiring to make sure everything was correct. Wouldn't you know it, I had the modules reversed of the order they needed to be in. In other words, front cylinders were being fed the spark from the rear cylinder hall sensor. Doah... No big. Simply change the location of the spark plug leads and swap Hall sensors connections. Now it is pretty much straight and all that needs to be done is tidy the wiring up. I am sure the way I have my ignitions wired is probably overkill, but I do like redundancy. Two 2600mah 7.4 Relions feeding two separate RC Excel ignition kill switches. Those two kill switches feeding two separated ignition modules. Each ignition module feeding a separate set of cylinders. I try to keep things organized so that later if I need to go back to something for what ever reason, It won't be a confusing mess. Example, Ignition battery #1 connects directly to ignition kill switch #1, (Which is the forward switch on top of the motor box) That kill switch controls the "RIGHT" ignition module. Which in turn delivers the spark to the forward cylinders. Battery #2 feeds the rear cylinders in the same type of configuration.

Tomorrow I will replace the 3w hall sensors with the RC Excel hall sensors. Then tidy up the wiring and that will do it for the engine install. If I had some sort of exhaust, I would probably start this thing tomorrow.

Next, four new NGK CM6 spark plugs gapped to .0185. One for each red head jug.

I needed to do a quick mock install of the headers to see where they were going to line up. For what ever reason, I got these dang things headed right down the can tunnel. They're supposed to be like this, right? LOL. I just remember the last time I had this engine on the Yak way back last year, the exhaust was so far away from going straight down the can tunnel. I am going to lay odds that with the rebuild after the mishap last year, everything got put back the way it was supposed to be. I dunno. I will order up the L80 canisters tomorrow. Hopefully they will be here by the time I am ready to install them.

After the quick check of the exhaust headers, I mounted the Taildragger RC Ignition Module "Vibra Mounts". I saved the bolt plate from the 210csts twin install. It layed back into it's original position.

After the module mounts were installed, I installed the twin RC Excel Ignition Modules.

Once the module were in place, I went through the wiring to make sure everything was correct. Wouldn't you know it, I had the modules reversed of the order they needed to be in. In other words, front cylinders were being fed the spark from the rear cylinder hall sensor. Doah... No big. Simply change the location of the spark plug leads and swap Hall sensors connections. Now it is pretty much straight and all that needs to be done is tidy the wiring up. I am sure the way I have my ignitions wired is probably overkill, but I do like redundancy. Two 2600mah 7.4 Relions feeding two separate RC Excel ignition kill switches. Those two kill switches feeding two separated ignition modules. Each ignition module feeding a separate set of cylinders. I try to keep things organized so that later if I need to go back to something for what ever reason, It won't be a confusing mess. Example, Ignition battery #1 connects directly to ignition kill switch #1, (Which is the forward switch on top of the motor box) That kill switch controls the "RIGHT" ignition module. Which in turn delivers the spark to the forward cylinders. Battery #2 feeds the rear cylinders in the same type of configuration.

Tomorrow I will replace the 3w hall sensors with the RC Excel hall sensors. Then tidy up the wiring and that will do it for the engine install. If I had some sort of exhaust, I would probably start this thing tomorrow.