You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC The new Dalton 300 SP / 330

- Thread starter orthobird

- Start date

WBPU

It is :

water based poly-urethane

Wonder if any different from the stuff you can get at Lowes?

They claim it dries in 20 minutes.

I did not have this experience.

It was still wet one hour later.

I have, in the past, used poly-urethane to glass, and the one I used took about 3 days to dry.

It is :

water based poly-urethane

Wonder if any different from the stuff you can get at Lowes?

They claim it dries in 20 minutes.

I did not have this experience.

It was still wet one hour later.

I have, in the past, used poly-urethane to glass, and the one I used took about 3 days to dry.

Jetpainter

640cc Uber Pimp

A lot of people like the Minwax Polycrylic. They claim it's lighter than Epoxy resin, but in all the testing I did a year or so ago I did not find that to be the case, for me anyway. I made several test panels that I weighed as I went, and the Polycrylic panels took more material and more primer to fill weave. It was easier to use, but the finished product with Z-Poxy finishing resin was better and lighter, from a professional painters standpoint. Other peoples results may vary, and everyone has their favorite. Use what works best for you.

I have cut out the hole in the bottom of the cowl, and was able to install the mounting screws and t-nuts for the cowl to the fuselage.

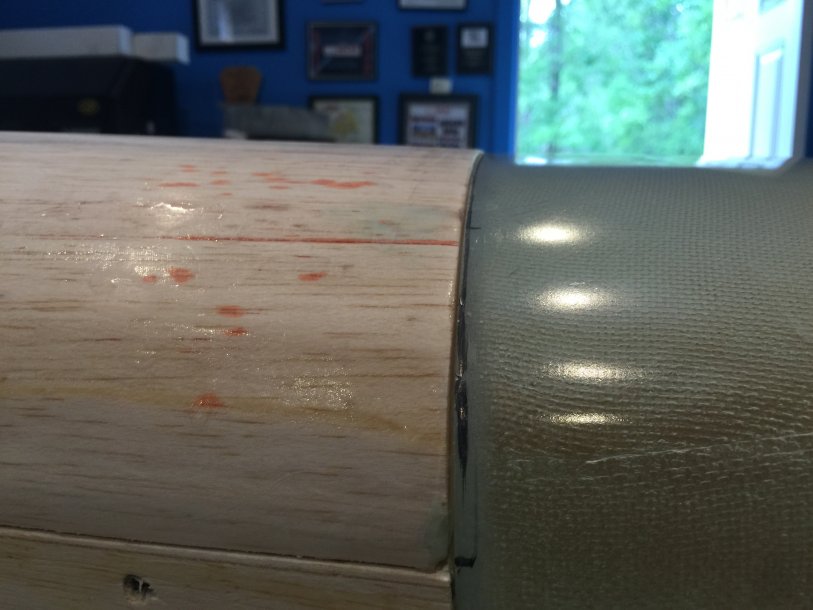

I want to demonstrate the small step off from cowl to the top of the hatch....

i then applied the Dolphin glaze to this, and used the wooden popsicle stick, to make it even, then I used a x-acto blade to split the difference before it cured.

once it is fully dry, I will sand it smooth and retake the picture. Once this is done, I can primer the cowl, hatch, canopy.

I want to demonstrate the small step off from cowl to the top of the hatch....

i then applied the Dolphin glaze to this, and used the wooden popsicle stick, to make it even, then I used a x-acto blade to split the difference before it cured.

once it is fully dry, I will sand it smooth and retake the picture. Once this is done, I can primer the cowl, hatch, canopy.

Maxwell1945

50cc

Hi Van, long time since I hear from you. Looks like you are almost done as well! Love the cuffs!

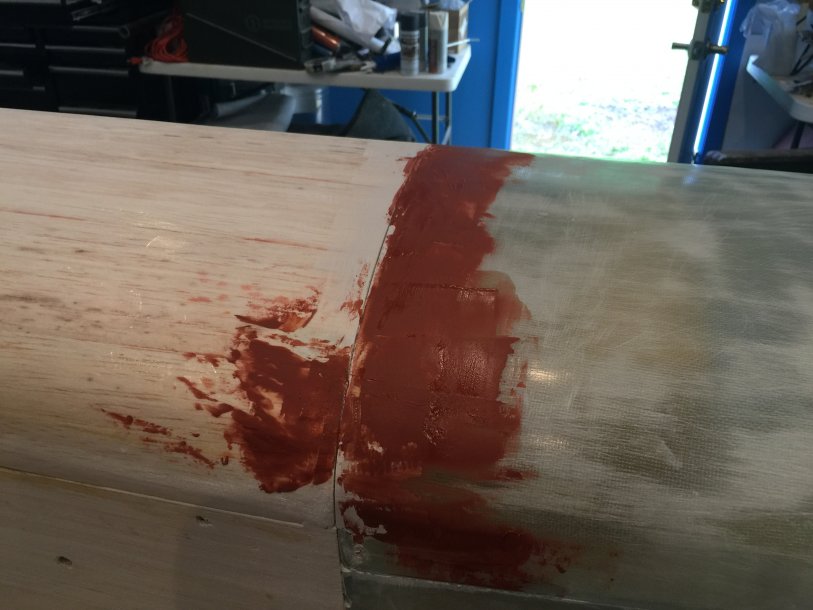

started to sand it down, and both by feel and looking at it, no more step off.

I am very happy with that.

Now, I want to fill the very small defects, and I used glazing putty here, so no mixing required.

once that cures, a final sanding, then I believe I can primer it all.

started to sand it down, and both by feel and looking at it, no more step off.

I am very happy with that.

Now, I want to fill the very small defects, and I used glazing putty here, so no mixing required.

once that cures, a final sanding, then I believe I can primer it all.

dhal22

GSN Sponsor Tier 1

A lot of people like the Minwax Polycrylic. They claim it's lighter than Epoxy resin, but in all the testing I did a year or so ago I did not find that to be the case, for me anyway. I made several test panels that I weighed as I went, and the Polycrylic panels took more material and more primer to fill weave. It was easier to use, but the finished product with Z-Poxy finishing resin was better and lighter, from a professional painters standpoint. Other peoples results may vary, and everyone has their favorite. Use what works best for you.

The key to Minwax poly is sanding sealer 1st. Keeps the weight down.