You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC The new Dalton 300 SP / 330

- Thread starter orthobird

- Start date

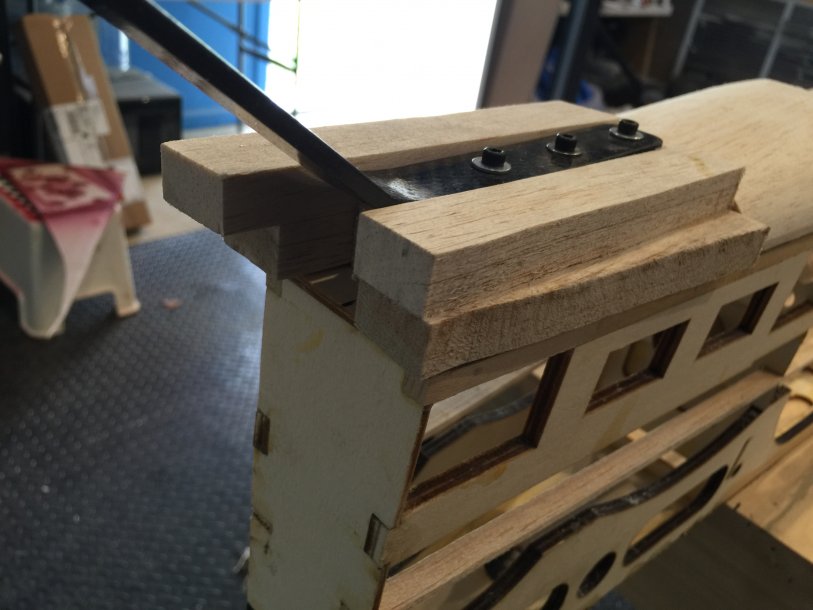

this plate or strip will actually go on the same side as the face of the blind nuts. But yes, when the time comes to glue on the tail wheel mount, I will mount the screws and use that to hold it in place while it cures, and your idea is also good with the vaseline. Thank you. You will see what I mean when I do that step.

Snoopy1

640cc Uber Pimp

If I may ask why did you not just bolt it down on the first plate with out the stand off. Or is the height that important. That will save weight and you can finish it off with 3/32 balsa sheets. And hide all the hardware.

Must say that is one nice plane and a great build.

Must say that is one nice plane and a great build.

good point, if the tail wheel is mounted directly to that plate, then the clearance will be much less. The rudder will be that much closer to the ground. almost an inch, I would say. Once I finish with this step, you will be able to see what I am doing. Hope that does not sound snooty, I do not mean it to be. Let me see If i can find some pictures of the standard ML version. If I do not do this, then the tail will be much lower than the standard ML version, as the standard ML has the stringers bak there.

found them!

here are some pictures from 2013, when I built the 1st ML.

this is the standard 300 ML tail, bottom view. where the tail wheel sits is on the same level as the bottom of the fuselage. This is not the case with the Dalton 300 SP, which is the version I am building now. Look at this picture, and the stringer that is in contact with RCS back, is the level where that cross brace ply plate is located. Too high for me.

Let me know If you can understand what I am trying to explain. IF not, I can try to clarify it more or even make a sketch of it.

best regards

Cam

found them!

here are some pictures from 2013, when I built the 1st ML.

this is the standard 300 ML tail, bottom view. where the tail wheel sits is on the same level as the bottom of the fuselage. This is not the case with the Dalton 300 SP, which is the version I am building now. Look at this picture, and the stringer that is in contact with RCS back, is the level where that cross brace ply plate is located. Too high for me.

Let me know If you can understand what I am trying to explain. IF not, I can try to clarify it more or even make a sketch of it.

best regards

Cam

Here is to give you an idea of what it will look like.

These will be glued on, and then shaped to contour, so it will have same shape as the bottom of the tail on a Dalton 300 ML.

However, I will wait til I glue the fuselage sides on, the belly pan, and the block before I put these on and sand them flush.

These will be glued on, and then shaped to contour, so it will have same shape as the bottom of the tail on a Dalton 300 ML.

However, I will wait til I glue the fuselage sides on, the belly pan, and the block before I put these on and sand them flush.

Here is that plate I made, to glue it all together, so you do not have to worry, years from now, about changing out the tail wheel spring, and then the blind nuts pop off. It would then become a real PITA to put them back in there. Possible, but more difficult.

Additionally, this airplane, with a 200 upfront, will have a tendency to be nose heavy. SO i would not core out any of the tail foam. If you are using a 150 with stock muffs, then go for it. Even a 170, go for making tail as light as possible.

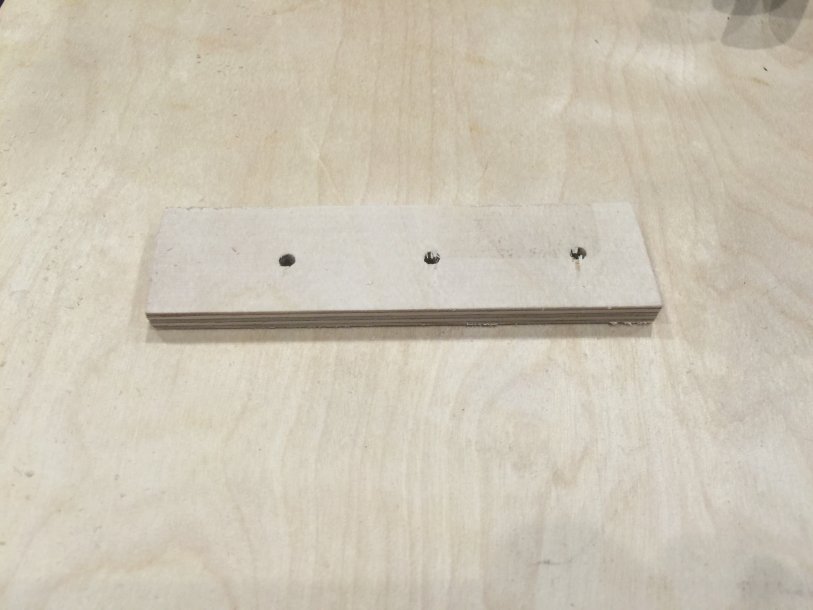

here is the plate, this will be glued in from the inside of the fuselage. The purpose of this is to cover the blind nuts, so they cannot pop off.

I have countersunk the wood, so there is full contact of the ply around to adhere to.

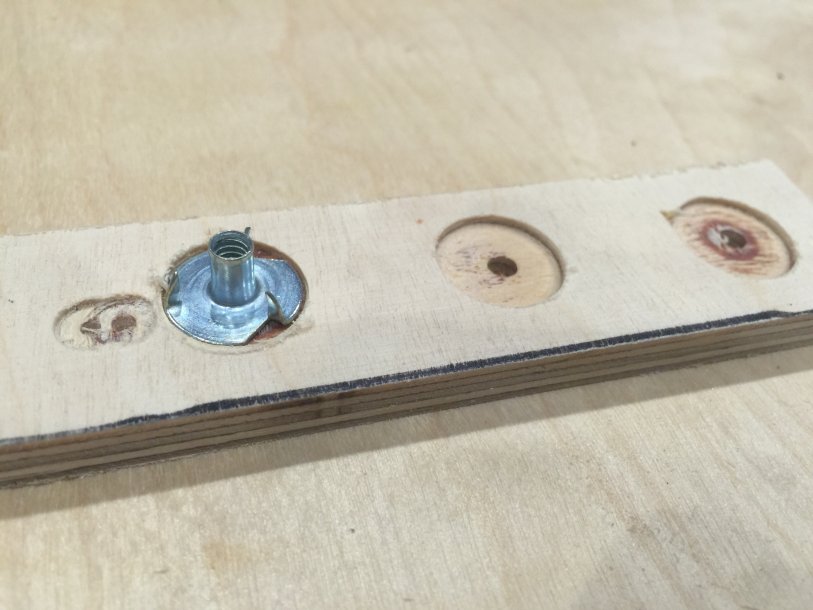

here are the exposed blind nuts:

currently, it is being glued in. When I get home from work, I will take the clamps off, and show what it looks like.

Additionally, this airplane, with a 200 upfront, will have a tendency to be nose heavy. SO i would not core out any of the tail foam. If you are using a 150 with stock muffs, then go for it. Even a 170, go for making tail as light as possible.

here is the plate, this will be glued in from the inside of the fuselage. The purpose of this is to cover the blind nuts, so they cannot pop off.

I have countersunk the wood, so there is full contact of the ply around to adhere to.

here are the exposed blind nuts:

currently, it is being glued in. When I get home from work, I will take the clamps off, and show what it looks like.