I have noticed recently on another forum, two different threads on motor mounts, one by an independent person and the other by Blazing star.

Blazing star makes what sort of what I am looking for, except, only for motors 120 and under. This is distributed by Extreme Flight. Was originally designed and manufactured by "gravy goodness", or something like that. LOL...

the DA 150, 170, and 200 all share the same mount pattern, which is 80 mm by 90 mm.

I have, for about 2 years, been trying to find a way to get someone to make me one, but at no avail.

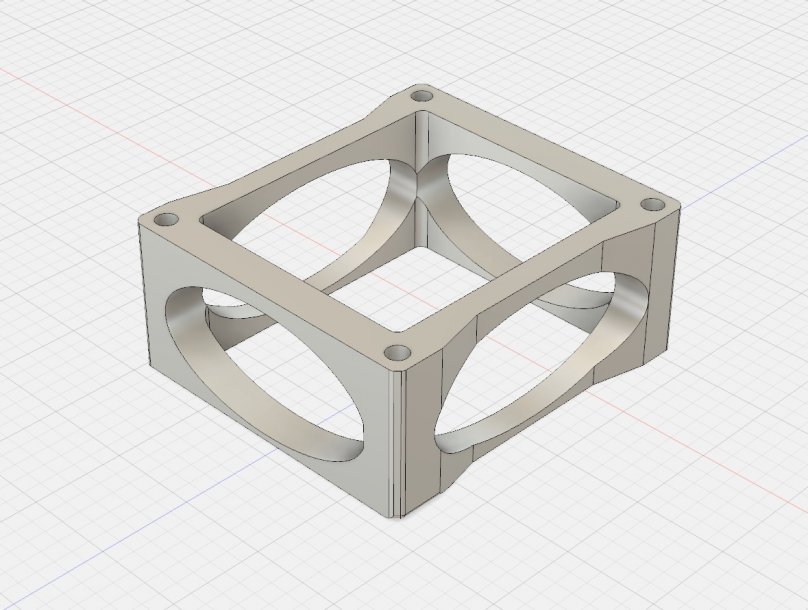

In the past 2 weeks, I have learned to use Autodesk Fusion 360, and I was able to make the model of the mount I am looking for.

I have forwarded this to several companies in USA. I was able to find these companies by making a Google search : "Custom CNC aluminum machining"

I got replies from several of them, and most will not do one or two, they want an order of over 100 of these bad boys.

Then, one replied, they can do it, for 840 dollars!!!

WOW, I would be nuts to pay that much money.

I actually have the aluminum and need to get it cut down to size, and maybe by shipping this to someone, they can machine it for me.

If anyone knows of someone with a CNC machine who can make this for me, please PM me.

I have the model of it in the auto cad file ( .iges)

thank you

Cam

Blazing star makes what sort of what I am looking for, except, only for motors 120 and under. This is distributed by Extreme Flight. Was originally designed and manufactured by "gravy goodness", or something like that. LOL...

the DA 150, 170, and 200 all share the same mount pattern, which is 80 mm by 90 mm.

I have, for about 2 years, been trying to find a way to get someone to make me one, but at no avail.

In the past 2 weeks, I have learned to use Autodesk Fusion 360, and I was able to make the model of the mount I am looking for.

I have forwarded this to several companies in USA. I was able to find these companies by making a Google search : "Custom CNC aluminum machining"

I got replies from several of them, and most will not do one or two, they want an order of over 100 of these bad boys.

Then, one replied, they can do it, for 840 dollars!!!

WOW, I would be nuts to pay that much money.

I actually have the aluminum and need to get it cut down to size, and maybe by shipping this to someone, they can machine it for me.

If anyone knows of someone with a CNC machine who can make this for me, please PM me.

I have the model of it in the auto cad file ( .iges)

thank you

Cam