You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mini lathe (and mill) discussion.

- Thread starter dhal22

- Start date

Snoopy1

640cc Uber Pimp

Most of your comments are over my head but I want to make my own stuff so I will figure it out. Still seems like that size is too much for our hobby.

If you can you will never regret buying it. Good tools are always a good investment, and they last a life time.

dhal22

GSN Sponsor Tier 1

Looks like a nice machine, like the power crossfeed and reverse feed. They are 25 miles from my home and never heard of them? The slim live center would be a good option if you with them.

Tony, what other brands are out there? I'm seeing a couple of brands but not many.

pawnshopmike

Staff member

Harbor Freight is probably good enough for what we do. I just bought a used Harbor Freight mini mill off a friend of mine. Hoping to pick it up sometime today.

TonyHallo

640cc Uber Pimp

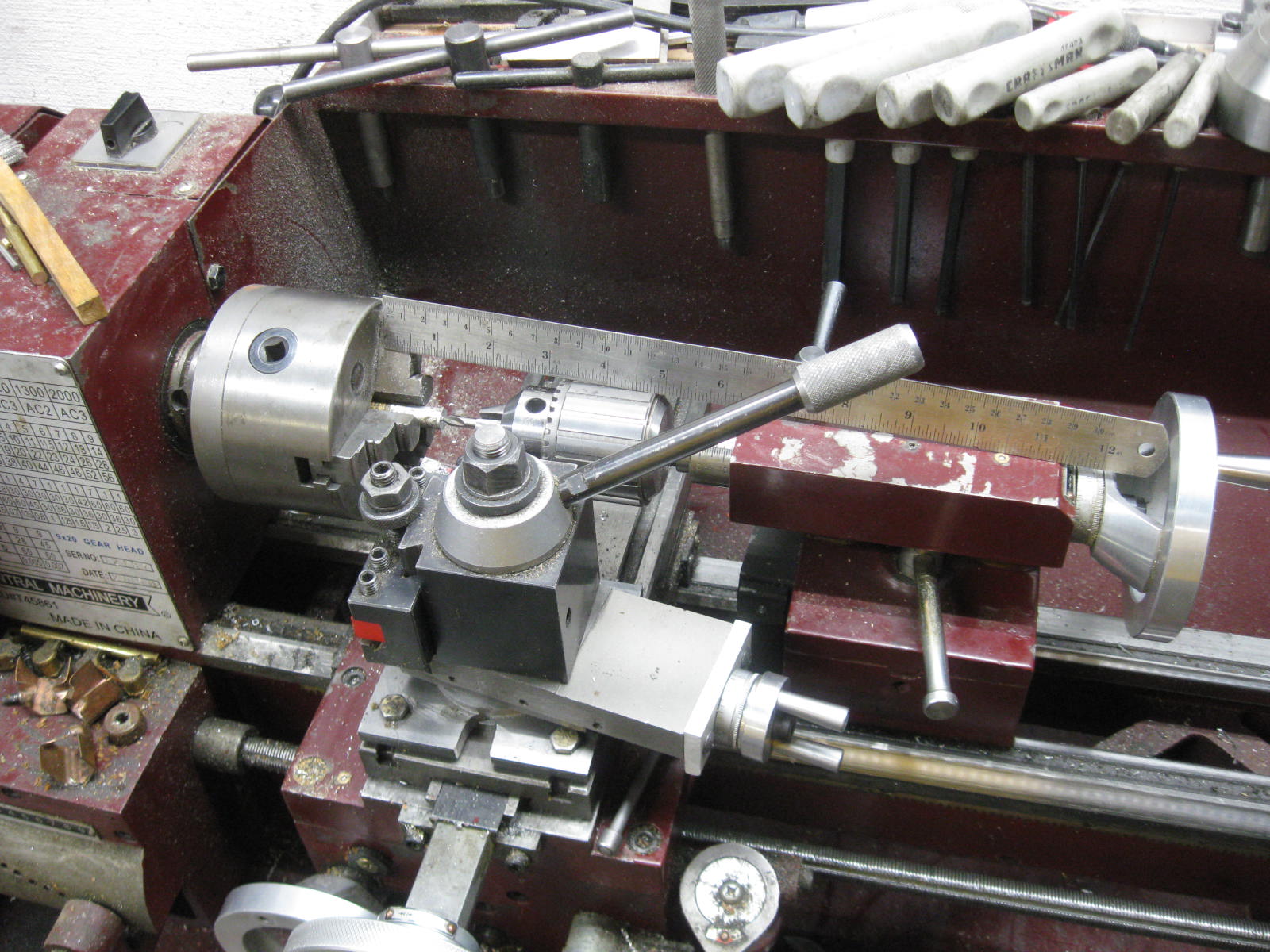

Here's a photo from yesterday, was center drilling a piece stock to hold the rod end screws while the heads were faced. Took 12" of the way just to drill, needed to push the tailstock out of the to tap, this is why a larger machine is better. I would get the 30" bed if possible

dhal22

GSN Sponsor Tier 1

Here's a photo from yesterday, was center drilling a piece stock to hold the rod end screws while the heads were faced. Took 12" of the way just to drill, needed to push the tailstock out of the to tap, this is why a larger machine is better. I would get the 30" bed if possible

So the PM1030v is now on the bigger side of my search.