You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Glassing and Painting techniques

- Thread starter Terryscustom

- Start date

Terryscustom

640cc Uber Pimp

That nasty four letter word "Work" has been getting in the way, but I did manage to prime a few of the test panels I've been working on. Some of them I sprayed with two coats of Nason 421-19 2K urethane primer with Nason 483-87 activator. I reduced the activated primer by about 10% with Nason 441-21 reducer to make it lay a little smoother.

Cool, I'm getting pretty pumped to do a fully painted plane now more than ever. I used that primer a couple of times now in the last month and have had extremely good results for an inexpensive product!

Jetpainter

640cc Uber Pimp

They are 24 sq".What is the area of the test panels?

They were done with the intention of testing fillers and primers and number of resin coats to see what combination yields the lightest, yet smooth and stable painting surface. The weight per square inch of these panels is higher than it would be on an airplane because I used 1.5 ounce cloth instead of .56 which I was out of at the time. Tonight I'm going to start on a few new ones with .56 ounce cloth and weigh them from start to finish with a paint mixing scale down to the tenth of a gram.

Jetpainter

640cc Uber Pimp

Nason has a lot of good, relatively inexpensive products. Another plus is availability since a lot of O'reilly auto parts stores carry it or can get it.Cool, I'm getting pretty pumped to do a fully painted plane now more than ever. I used that primer a couple of times now in the last month and have had extremely good results for an inexpensive product!

got smoke?

50cc

the West systems 105 was what I was wanting to trythanks for your quick reply at least now I know I'm on the right track thanksI use West systems only. Resin is 105 and I use slow hardener 206 for all my parts. I have tried some other brands but like the west systems better. Some may like polyester but I have many molds that were made with poly from years back and they all have cracks in them.

For you project if you can get to the inside I would sand with some 80 grit and then some with 180 to remove any residue in a bout a 2”-3” line down the crack. Mix up some glue and mix in 1 to 1 to 2 ratio of micro balloons and cabosil and flocked cotton fiber as a fill brush this along crack then lay in 2 layers of 4oz fiberglass cloth. You can also use the mixed fill on the cracked seam on the outside once the inside was done. This mix will sand fairly easy.

This would of course depend on the damge area.

Capt.Roll

70cc twin V2

They are 24 sq".

They were done with the intention of testing fillers and primers and number of resin coats to see what combination yields the lightest, yet smooth and stable painting surface. The weight per square inch of these panels is higher than it would be on an airplane because I used 1.5 ounce cloth instead of .56 which I was out of at the time. Tonight I'm going to start on a few new ones with .56 ounce cloth and weigh them from start to finish with a paint mixing scale down to the tenth of a gram.

Thanks. Using .56 cloth would not add much weight. I'd like to paint a set of wings for my 104" EF Extra, it seems like glass plus paint would not be much heavier than mono/ultrakote.

Jetpainter

640cc Uber Pimp

Last night I started on several more test panels. This time with lightweight glass cloth. I weighed them carefully with a paint scale before glassing and used hair spray on some. This time I should be able to tell if the hair spray panels use less resin of not. I'll sand and weigh them tonight and see.

Last night before leaving work I sprayed two of the original panels with epoxy primer. Today I sanded and weighed them.

Panel #1:

Weight after cloth and 1 coat of resin, sanded. 0.29 ounces

Weight after 2nd coat of resin, sanded. 0.29 ounces

Weight after 1 coat of joint compound, sanded. 0.29 ounces

weight after 2 coats of Nason epoxy primer, sanded 0.30 ounces

The technique used on this panel in my opinion is the best of the ones I've done. It gained the least weight from glass to ready to paint and I don't think it will have any shrinkage down the road.

Panel #2:

Weight after cloth and 1 coat of resin, sanded. 0.27 ounces

Weight after 1st coat of joint compound, sanded 0.29 ounces

Weight after 2nd coat of joint compound, sanded 0.29 ounces

Weight after 2 coats of Nason epoxy primer, sanded 0.31 ounces

Though this panel turned out well it gained more weight than others techniques. Also it showed a lot of areas in the primer that has soaked into the joint compound. It sanded out well, but I would have concerns with shrinkage out in the hot sun.

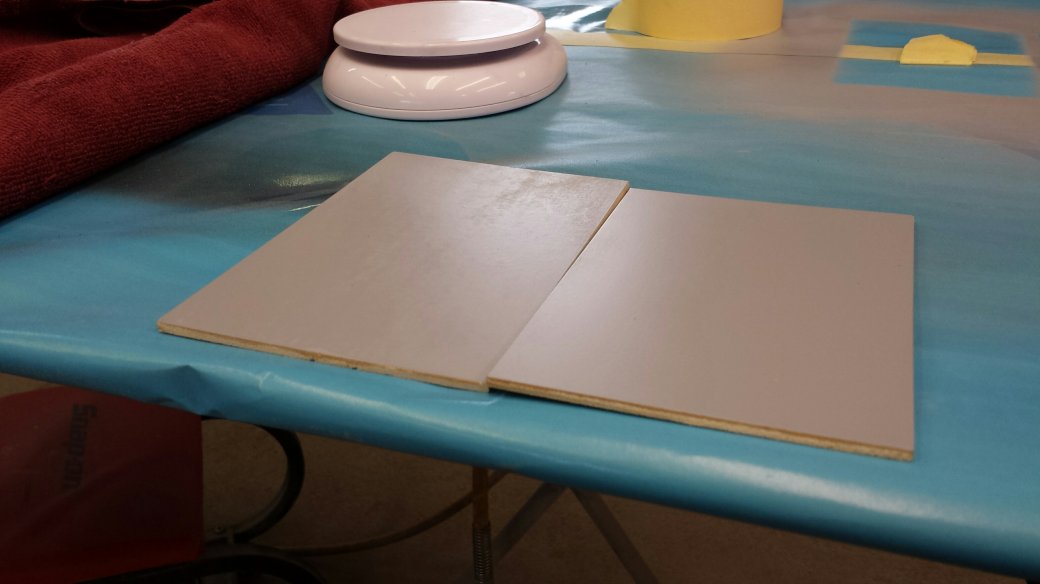

The panel on the left is the one that the primer soaked into the joint compound. The right one was nice and smooth.

Last night before leaving work I sprayed two of the original panels with epoxy primer. Today I sanded and weighed them.

Panel #1:

Weight after cloth and 1 coat of resin, sanded. 0.29 ounces

Weight after 2nd coat of resin, sanded. 0.29 ounces

Weight after 1 coat of joint compound, sanded. 0.29 ounces

weight after 2 coats of Nason epoxy primer, sanded 0.30 ounces

The technique used on this panel in my opinion is the best of the ones I've done. It gained the least weight from glass to ready to paint and I don't think it will have any shrinkage down the road.

Panel #2:

Weight after cloth and 1 coat of resin, sanded. 0.27 ounces

Weight after 1st coat of joint compound, sanded 0.29 ounces

Weight after 2nd coat of joint compound, sanded 0.29 ounces

Weight after 2 coats of Nason epoxy primer, sanded 0.31 ounces

Though this panel turned out well it gained more weight than others techniques. Also it showed a lot of areas in the primer that has soaked into the joint compound. It sanded out well, but I would have concerns with shrinkage out in the hot sun.

The panel on the left is the one that the primer soaked into the joint compound. The right one was nice and smooth.

dhal22

GSN Sponsor Tier 1

That nasty four letter word "Work" has been getting in the way, but I did manage to prime a few of the test panels I've been working on.

I like my job, I own my own company, but man it get's in the way of building and flying.

Terryscustom

640cc Uber Pimp

WOW , awesome thread you started Terry .Very informative . I am ready to graduate from spray cans .

Spray cans!!!!!!!!!!!!!!!!!!