Time to build a fuel tank. I've built a lot of PSP fuel tanks and never had one leak, fault in any way. Here is how I do it:

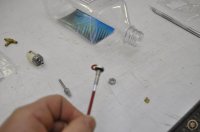

- The O-ring fitting has an allen head in it so it's easy to hold.

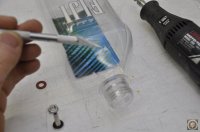

- Decide where you want your fitting and use a sharp hobby knife to make about a 1/8" square hole.

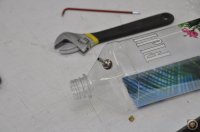

- Use a tapered carbide dremel tool to enlarge the hole so it is JUST large enough for the threads to slide through, the threads should not "bite" and thread through the hole. If you get the hole too large........drink another bottle of water and start over.

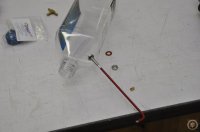

- Install the fitting from the inside, install the washer and nut, tighten until snug.

- I use Viton inside the tank. The barbs on the cap itself are very sharp and the fitting is larger than average so I don't use any type of zip tie, you can if it makes you happy.

- I like to install a 3" section of brass tubing inside the viton hose to keep it from flopping towards the front of the tank too far. If it is difficult I put a drop of redline in the hose and then it slides in easily. Push it in with an allen wrench to where you want it.

- I like the extra large felt clunks from taildraggerrc.com. I do use a zip tie on this because the barb is kinda smooth.

- Make sure the O-ring is in the cap and install on the bottle tightly.

I like a two line system to save weight and the sheer volume of hoses, fittings etc. required. It's always been effective for me, just make sure you use a quality fuel dot and a good quality "T" fitting a couple inches in front of the tank.