Orelelbaz6

30cc

Hey Everyone! Welcome to the build log for the new Aerobeez 105" Extra 330 Reaper. Aerobeez has done a great job with this kit. Aerobeez already cut down a few hours of the build but pre hinging all of you surfaces.

My setup will be:

-DLA-116cc Engine

- (7) Hitec HSB-9380th servos all around

-Hitec HS-5665 on throttle

- Xoar 28x8

-(2) Gens Ace 2s 3500mah RX pack

Before we start building, I highly recommend using lock-tight for every single screw in the airplane.

I like to lay everything out on the table before i begin to make sure i have everything. Than I feel like it is an important to go through all the joints in the fuselage with thin CA.

Next locate your wing, stabilizer, and rudder bag and remove all of your control horns and lay them out in front of you. Using sand paper, sand the bottom part of the control horn as seen in the picture above.

Next locate all of your ball links and linkages, they should already be installed together from the factory. The 4 shortest ones are for your ailerons, the 2 medium sized ones are for your elevators, and the longest one is for you rudder. Slide the control horn plate into 2 control horns and screw in your ball links to the control horn. Use lock tight for the screws. Repeat this step to all of your control horns. I am going with the push-pull method in this build in order to get he servo feel i desire.

Locate the placement for the control horns on the wing. They are located a underneath the servo bay on the aileron and a little to the side. Cut the slits open with a knife so that you can slide in the control horns later.(The wing comes with a option to use 3 servos, i am only using 2 servos so i am using the one that is furthest away from the cord of the wing and the one that is closest, i am not using the middle servo)

Next slide in your control horns and cut the are around it with a sharp knife.

Using masking tape, mask the area around the control horn. This is so epoxy wont get on the covering when we glue in the control horn.

Remove the control horn and pull away the covering we cut earlier.

Now repeat these steps to all of the control surfaces.

At this point we can begin mixing our epoxy. I use 5 minute epoxy but for this step i recommend using at least a 15 minute. Once our epoxy is mixed we can put some epoxy on the control surface itself and also on the control horn, on the side that is going to be inserted into the wing. Now install the control horn the control horn.

Using a paper towel that has been dampened with acetone clean away the excess epoxy.

While the epoxy is still wet, peel away the masking tape an go over that area with a paper towel dampened with acetone. Continue this step to all of the control surfaces.

Now locate your carbon fiber landing gear, wheel pants, gear cuffs, and landing gear accessory bag.

Slide the gear cuffs onto the landing gear, make sue its on the correct way. The front of the landing gear is the flat side, the rear is a bit tapered as you can see in the picture above. The right side of the gear in the picture is the front. The shortest part of the gear cuff should be in the front of the rear, the rear part of the cuff extends out a little bit more for looks. Do not glue in the cuffs yet!

Now screw in the axle into the carbon fiber landing gear. Make sure to put locktite on the threads of the axle!

Find all four of the wheel collars and take them out of the bag. Remove all of the set screws and lay them out on the table. Put locktite in all of the collars where the set screw goes in, this is a very important step! Without the locktite the set screws are bound to vibrate loose! Put the set screws into the collars but do not tighten all the way.

Slide the collar onto he axle, do not tighten i yet. Put the wheel pant where it is supposed to be in order to determine the distance between the collar and the axle. Once you have determined the proper distance for the collar to be tighten the collar, slide on the wheel, slide on the other collar and tighten. Repeat the same steps for the other side. Aerobeez has taken the liberty of putting the blind nut in the wheel pants for you, but i do not like putting the wheel pants on the landing gear just yet because i do not want them to get scratched. So put in your bolts in the wheel pants and keep them in a safe place until he end.

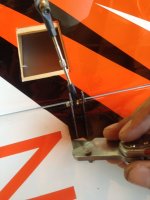

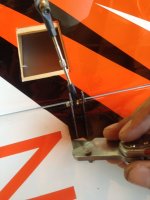

Flip the airplane over to its underside, remove the gear cover from where it is supposed to be and test fit the main gear.

Slide he bolts though the gear cover plate.

Once you know the main gear fits, locate the 4 bolts and nuts that are needed to install the lading gear, put the washer on the screw and some locktight on the threads.

Slide the screws in place through the bottom side of the air frame.

Put the washers and nuts on and tighten.

Move your gear cuffs to the desired location and put a few strips of masking tape on the bottom of the gear cuff.

Slide down the gear cuff and place some epoxy on the place where the gear cuff meets the landing gear.

Slide the gear cuff in place, remove the masking tape, and clean up excess epoxy.

Repeat these steps for both sides.

At this point you can also remove the tape holding the hatch i the back as shown in the picture above.

Locate the wood screws that are meant to screw the hatch to the wood. Now in the log, i did not cut away the covering in the hatches but over time i found that it helps with cooling so i recommend to cut away the covering in the holes.

Install the hatches.

Now the easiest part of the whole build, hinging the rudder, you must first find the rod used as a pin for the rudder hinges and the collar attached to it. Remove the collar, and line up the rudder, slide the pin though the rudder hinge slot.

Once you have slipped the rod through put a collar on the bottom side of the rod that sticks out, lock tight the set screw.

Now locate your tail wheel assembly, springs, wood screw, and the three bolt all supplied with the kit. Aerobeez took the liberty of pre-installing the tail wheel on the tail wheel assembly to help you get your plane flying just a little bit faster!

Slide the bolts into the tail wheel assembly and put locktit on the threads of all the bolts.

Bolt the tail wheel assembly in place

Now take both of the springs and bend the end about 270degrees.

Slide the bent part of the springs into the holes on the assembly.

Slide the bent piece into the spring.

Follow the same steps to this piece.

Pull until the springs have tension.

Now screw it in place.

Once the wing control horns have dried, we can now work on connecting the servos to it. Remove the servo bays from the wings and remove the covering as shown in the picture.

Attach the arms to your servos, for servos i chose the Hitec HSB-9380th servo.

Screw the servo in place. (I chose to cut off the wood on the side because my servo arm was rubbing on it.

Locate the line in the fuselage to help run your servo extensions to the outside of the wing.

Tie one end to your servo extension.

Pull through the end. Repeat this step for both wing servos and for both wings.

Screw your servo bay in with the supplied wood screws, and connect your servo to the ball links, remember to use locktite. Repeat this step for both wings.

Cut away the covering for where the servo arm will stick out of.

Screw in your elevator servo, and connect your push rod to your servo arm. Remember to use locktite.

Cut the servo hole for the rudder and elevators. The rudder servo location is directly under the elevators and the elevator servo locations are directly in front of the elevators on either side of the fuselage. On the right side of the fuselage inside the tail, there is the piece of string used to run the servo extensions to the fuselage. At the end, you will need to use a bit of grey covering that comes with the kit ad cover up the right square so that it won show up when you put the elevators on, but for building purposes it is necessary to cut this hole.

Run all of your servo extensions through this hole and tie them to the string like shown.

Pull through the inside of the fuselage.

Now you can install the fuel tank. Arobeez has made his step supper easy by pre-plumbing you fuel tank for you. Remember to remove the spare o-rings that come inside.

Remove the covering from the little hole shown above, and screw in your fuel dot.

Run your fuel lines to the necessary locations.

Now we can install the engine, tape your engine mounting template to the firewall. Make sure to line up the lines to he firewall.

Drill out the holes, and mount your engine. Remember to use locktite.

Install your throttle servo in the desired location and connect it to the engine.

Than cut the holes in your cowl by lining it up under your engine.

You are now complete with your Aerobeez 105" Reaper Extra 330sc! Happy Flying!

PRO TIPS:

CG-

Using a DLA-116cc engine with the rudder servo in the rear and a Gens Ace 3500mAh 2s RX pack strapped righ behind the wing tube i got the CG to balance right on the wing tube.

Throws:

For 3D throws i recommend starting off on the elevators and rudder at around 55degrees, and the ailerons at around 30degrees. I generally start off with around 60% expo on the radio. Work your way from these measurements at roughly 5degree increments.

For low rates i recommend setting everything at around 20degrees with around 50% expo and work your way from there at roughly 3degree increments.

Final Thoughts:

Aerobeez did a real good job on this frame, this frame snaps clean, and tracks strait and true. For 3D it harriers rock solid and over all has the same good flying charictoristics from its younger brothers.

-Orel Elbaz

My setup will be:

-DLA-116cc Engine

- (7) Hitec HSB-9380th servos all around

-Hitec HS-5665 on throttle

- Xoar 28x8

-(2) Gens Ace 2s 3500mah RX pack

Before we start building, I highly recommend using lock-tight for every single screw in the airplane.

I like to lay everything out on the table before i begin to make sure i have everything. Than I feel like it is an important to go through all the joints in the fuselage with thin CA.

Next locate your wing, stabilizer, and rudder bag and remove all of your control horns and lay them out in front of you. Using sand paper, sand the bottom part of the control horn as seen in the picture above.

Next locate all of your ball links and linkages, they should already be installed together from the factory. The 4 shortest ones are for your ailerons, the 2 medium sized ones are for your elevators, and the longest one is for you rudder. Slide the control horn plate into 2 control horns and screw in your ball links to the control horn. Use lock tight for the screws. Repeat this step to all of your control horns. I am going with the push-pull method in this build in order to get he servo feel i desire.

Locate the placement for the control horns on the wing. They are located a underneath the servo bay on the aileron and a little to the side. Cut the slits open with a knife so that you can slide in the control horns later.(The wing comes with a option to use 3 servos, i am only using 2 servos so i am using the one that is furthest away from the cord of the wing and the one that is closest, i am not using the middle servo)

Next slide in your control horns and cut the are around it with a sharp knife.

Using masking tape, mask the area around the control horn. This is so epoxy wont get on the covering when we glue in the control horn.

Remove the control horn and pull away the covering we cut earlier.

Now repeat these steps to all of the control surfaces.

At this point we can begin mixing our epoxy. I use 5 minute epoxy but for this step i recommend using at least a 15 minute. Once our epoxy is mixed we can put some epoxy on the control surface itself and also on the control horn, on the side that is going to be inserted into the wing. Now install the control horn the control horn.

Using a paper towel that has been dampened with acetone clean away the excess epoxy.

While the epoxy is still wet, peel away the masking tape an go over that area with a paper towel dampened with acetone. Continue this step to all of the control surfaces.

Now locate your carbon fiber landing gear, wheel pants, gear cuffs, and landing gear accessory bag.

Slide the gear cuffs onto the landing gear, make sue its on the correct way. The front of the landing gear is the flat side, the rear is a bit tapered as you can see in the picture above. The right side of the gear in the picture is the front. The shortest part of the gear cuff should be in the front of the rear, the rear part of the cuff extends out a little bit more for looks. Do not glue in the cuffs yet!

Now screw in the axle into the carbon fiber landing gear. Make sure to put locktite on the threads of the axle!

Find all four of the wheel collars and take them out of the bag. Remove all of the set screws and lay them out on the table. Put locktite in all of the collars where the set screw goes in, this is a very important step! Without the locktite the set screws are bound to vibrate loose! Put the set screws into the collars but do not tighten all the way.

Slide the collar onto he axle, do not tighten i yet. Put the wheel pant where it is supposed to be in order to determine the distance between the collar and the axle. Once you have determined the proper distance for the collar to be tighten the collar, slide on the wheel, slide on the other collar and tighten. Repeat the same steps for the other side. Aerobeez has taken the liberty of putting the blind nut in the wheel pants for you, but i do not like putting the wheel pants on the landing gear just yet because i do not want them to get scratched. So put in your bolts in the wheel pants and keep them in a safe place until he end.

Flip the airplane over to its underside, remove the gear cover from where it is supposed to be and test fit the main gear.

Slide he bolts though the gear cover plate.

Once you know the main gear fits, locate the 4 bolts and nuts that are needed to install the lading gear, put the washer on the screw and some locktight on the threads.

Slide the screws in place through the bottom side of the air frame.

Put the washers and nuts on and tighten.

Move your gear cuffs to the desired location and put a few strips of masking tape on the bottom of the gear cuff.

Slide down the gear cuff and place some epoxy on the place where the gear cuff meets the landing gear.

Slide the gear cuff in place, remove the masking tape, and clean up excess epoxy.

Repeat these steps for both sides.

At this point you can also remove the tape holding the hatch i the back as shown in the picture above.

Locate the wood screws that are meant to screw the hatch to the wood. Now in the log, i did not cut away the covering in the hatches but over time i found that it helps with cooling so i recommend to cut away the covering in the holes.

Install the hatches.

Now the easiest part of the whole build, hinging the rudder, you must first find the rod used as a pin for the rudder hinges and the collar attached to it. Remove the collar, and line up the rudder, slide the pin though the rudder hinge slot.

Once you have slipped the rod through put a collar on the bottom side of the rod that sticks out, lock tight the set screw.

Now locate your tail wheel assembly, springs, wood screw, and the three bolt all supplied with the kit. Aerobeez took the liberty of pre-installing the tail wheel on the tail wheel assembly to help you get your plane flying just a little bit faster!

Slide the bolts into the tail wheel assembly and put locktit on the threads of all the bolts.

Bolt the tail wheel assembly in place

Now take both of the springs and bend the end about 270degrees.

Slide the bent part of the springs into the holes on the assembly.

Slide the bent piece into the spring.

Follow the same steps to this piece.

Pull until the springs have tension.

Now screw it in place.

Once the wing control horns have dried, we can now work on connecting the servos to it. Remove the servo bays from the wings and remove the covering as shown in the picture.

Attach the arms to your servos, for servos i chose the Hitec HSB-9380th servo.

Screw the servo in place. (I chose to cut off the wood on the side because my servo arm was rubbing on it.

Locate the line in the fuselage to help run your servo extensions to the outside of the wing.

Tie one end to your servo extension.

Pull through the end. Repeat this step for both wing servos and for both wings.

Screw your servo bay in with the supplied wood screws, and connect your servo to the ball links, remember to use locktite. Repeat this step for both wings.

Cut away the covering for where the servo arm will stick out of.

Screw in your elevator servo, and connect your push rod to your servo arm. Remember to use locktite.

Cut the servo hole for the rudder and elevators. The rudder servo location is directly under the elevators and the elevator servo locations are directly in front of the elevators on either side of the fuselage. On the right side of the fuselage inside the tail, there is the piece of string used to run the servo extensions to the fuselage. At the end, you will need to use a bit of grey covering that comes with the kit ad cover up the right square so that it won show up when you put the elevators on, but for building purposes it is necessary to cut this hole.

Run all of your servo extensions through this hole and tie them to the string like shown.

Pull through the inside of the fuselage.

Now you can install the fuel tank. Arobeez has made his step supper easy by pre-plumbing you fuel tank for you. Remember to remove the spare o-rings that come inside.

Remove the covering from the little hole shown above, and screw in your fuel dot.

Run your fuel lines to the necessary locations.

Now we can install the engine, tape your engine mounting template to the firewall. Make sure to line up the lines to he firewall.

Drill out the holes, and mount your engine. Remember to use locktite.

Install your throttle servo in the desired location and connect it to the engine.

Than cut the holes in your cowl by lining it up under your engine.

You are now complete with your Aerobeez 105" Reaper Extra 330sc! Happy Flying!

PRO TIPS:

CG-

Using a DLA-116cc engine with the rudder servo in the rear and a Gens Ace 3500mAh 2s RX pack strapped righ behind the wing tube i got the CG to balance right on the wing tube.

Throws:

For 3D throws i recommend starting off on the elevators and rudder at around 55degrees, and the ailerons at around 30degrees. I generally start off with around 60% expo on the radio. Work your way from these measurements at roughly 5degree increments.

For low rates i recommend setting everything at around 20degrees with around 50% expo and work your way from there at roughly 3degree increments.

Final Thoughts:

Aerobeez did a real good job on this frame, this frame snaps clean, and tracks strait and true. For 3D it harriers rock solid and over all has the same good flying charictoristics from its younger brothers.

-Orel Elbaz