You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Scale 18% De Havilland DHC-2 Beaver by MR Aerodesign

- Thread starter WMcNabb

- Start date

WMcNabb

150cc

A bit more sheeting, carving and sanding to go. Then glass.Nice Wade, fabric soon?

WMcNabb

150cc

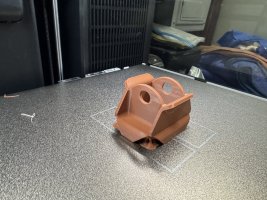

The jack pad is comprised of 5 individual components which were modeled from the original Beech drawings and then modified to fit the airplane. The pieces are from 1/8” sheet chrome moly steel, will be laser cut and then welded together to create the final part.

I’ll find out which specific material we have sourced and which service we’re using. The process was simply sending the CAD files and then receiving a quote. We chose the standard service meaning pieces by the end of the month. Expedited service was available with pieces arriving in 2-3 days.

I’ll find out which specific material we have sourced and which service we’re using. The process was simply sending the CAD files and then receiving a quote. We chose the standard service meaning pieces by the end of the month. Expedited service was available with pieces arriving in 2-3 days.

Last edited: