You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

IMAC The new Dalton 300 SP / 330

- Thread starter orthobird

- Start date

Bartman

Defender of the Noob!

good thing you let all the spots dry (from where your sweat was dripping onto the balsa!) before you took the photos!

would have been fun to watch a heartrate monitor as you stepped up to cut them! unless you've done it a bunch of times before, then it's business as usual.

i've never done foam wings so it's looks a little scary from where i'm sitting (in case you didn't figure that out!).

would have been fun to watch a heartrate monitor as you stepped up to cut them! unless you've done it a bunch of times before, then it's business as usual.

i've never done foam wings so it's looks a little scary from where i'm sitting (in case you didn't figure that out!).

sparkx38

50cc

LOL. I have driven some short distances. Still feel like a bobble head doll when riding in a car. Been practicing every day. (with my stick plane).hello Stacey, how are you now? Driven a car yet? been out flying / practicing for next weekend?

Sent from my XT1254 using Tapatalk

good thing you let all the spots dry (from where your sweat was dripping onto the balsa!) before you took the photos!

would have been fun to watch a heartrate monitor as you stepped up to cut them! unless you've done it a bunch of times before, then it's business as usual.

i've never done foam wings so it's looks a little scary from where i'm sitting (in case you didn't figure that out!).

I thought you were kidding with me.

OK, I take it you have some insight into that step, otherwise, you would not have made the comment.

Many different ways of doing that step...

This will be my 6th pair of wings that I prepare that are foam core and balsa sheeted, for 40% airplanes.

I will elaborate...

#1 . have someone else do it for you.... this is what I did on the 1st set of wings, in fact, Tony Russo sheeted them for me, and then my partner, who is a hand surgeon, he cut them out for me, in his shop, using a large band saw. He did a great job!!

2. the 2nd set of wings, I did it myself, using my small band saw....

not really a problem, since you make sure you err on the '"buffer zone", and not cut into the good sheeting, but the one that will be removed, since we remove a 1" strip.

the 3rd way of doing it, which is much easier.

is to get a long ruler, and mark out the aileron on both sides, and using a very sharp blade, cut thru the balsa only, using the ruler as a guide.

do both sides, then remove the balsa strip, and then using a hot wire, cut thru the foam, the balsa will be the guide. it is, the easiest way of doing it, and safest. Also, you do not want to use any thing that is too hot, as this will burn more foam, and you will have a depression on the surface.

no matter which way you do it, I use a sand belt on a flat surface, and then move the wing and the aileron to and fro, until it is perfectly flat and smooth. Just a few strokes is all that is required. then you can glue on the LE and TE of the hinge line.

Bartman

Defender of the Noob!

@orthobird i was just kidding, too much caffeine this morning maybe. but i really haven't ever had the pleasure of a set of foam wings on the bench.

you don't need me to tell you the plane's looking great but I'll tell you anyway, the plane's looking great!

you don't need me to tell you the plane's looking great but I'll tell you anyway, the plane's looking great!

here is an update... at this time, the build is going very slowly. I do one step per day or every few days. SO it is a slow crawling speed.

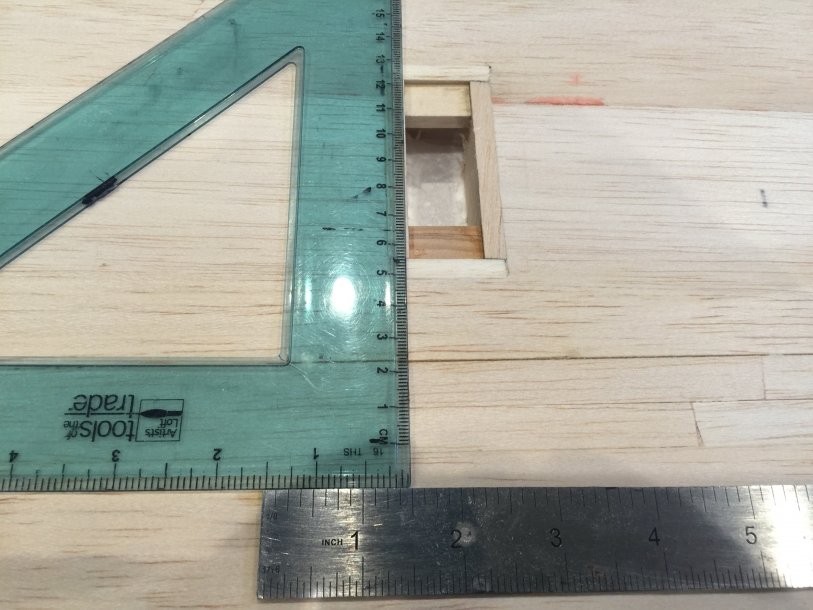

both servo boxes are glued in and sanded flush, in both wings.

next is to calculate the position for the center of the hard point. I will be using 1.25" servo arms, but I will also make sure that the distance from the hinge line to the control horn is at least 1.25" as well.

this is the hole for making the tunnel, using my copper tube, however, because I will be using an MPX plug that connects into the fuselage side, therefore, there has to be room in the root side of the wing for the wires to "pocket" into. This will be demonstrated much later.

this was done using a router....

will not get to do much more for now. I have a contest in Little Rock this weekend, so that will be fun. Wish me luck....

both servo boxes are glued in and sanded flush, in both wings.

next is to calculate the position for the center of the hard point. I will be using 1.25" servo arms, but I will also make sure that the distance from the hinge line to the control horn is at least 1.25" as well.

this is the hole for making the tunnel, using my copper tube, however, because I will be using an MPX plug that connects into the fuselage side, therefore, there has to be room in the root side of the wing for the wires to "pocket" into. This will be demonstrated much later.

this was done using a router....

will not get to do much more for now. I have a contest in Little Rock this weekend, so that will be fun. Wish me luck....

TazmanianDevil

Xtreme by DeFinition !

Awesome building thread. Great job with the cowl.